Considering the demographic development and the fact that the baby boomers will retire within the next

fifteen years, industrial production will have to be guaranteed in the future with increasingly scarce human

resources. A drastic population decline is also forecast in China. Thus, the disappearance of the world's

extended workbench is a very realistic scenario. For production-oriented economies, digitalization to

automate all processes is an increasingly important topic. Digitalization and Industry 4.0 are not a "luxury",

but a necessity to maintain innovation and production with significantly less manpower in the future.

In this context, digitalization in the sense of Industry 4.0 serves to achieve optimal efficiency in

automation and to seamlessly link the entire digital process chain from design to construction to

manufacturing in the entire lifecycle of a product. This applies to classic production methods but also to

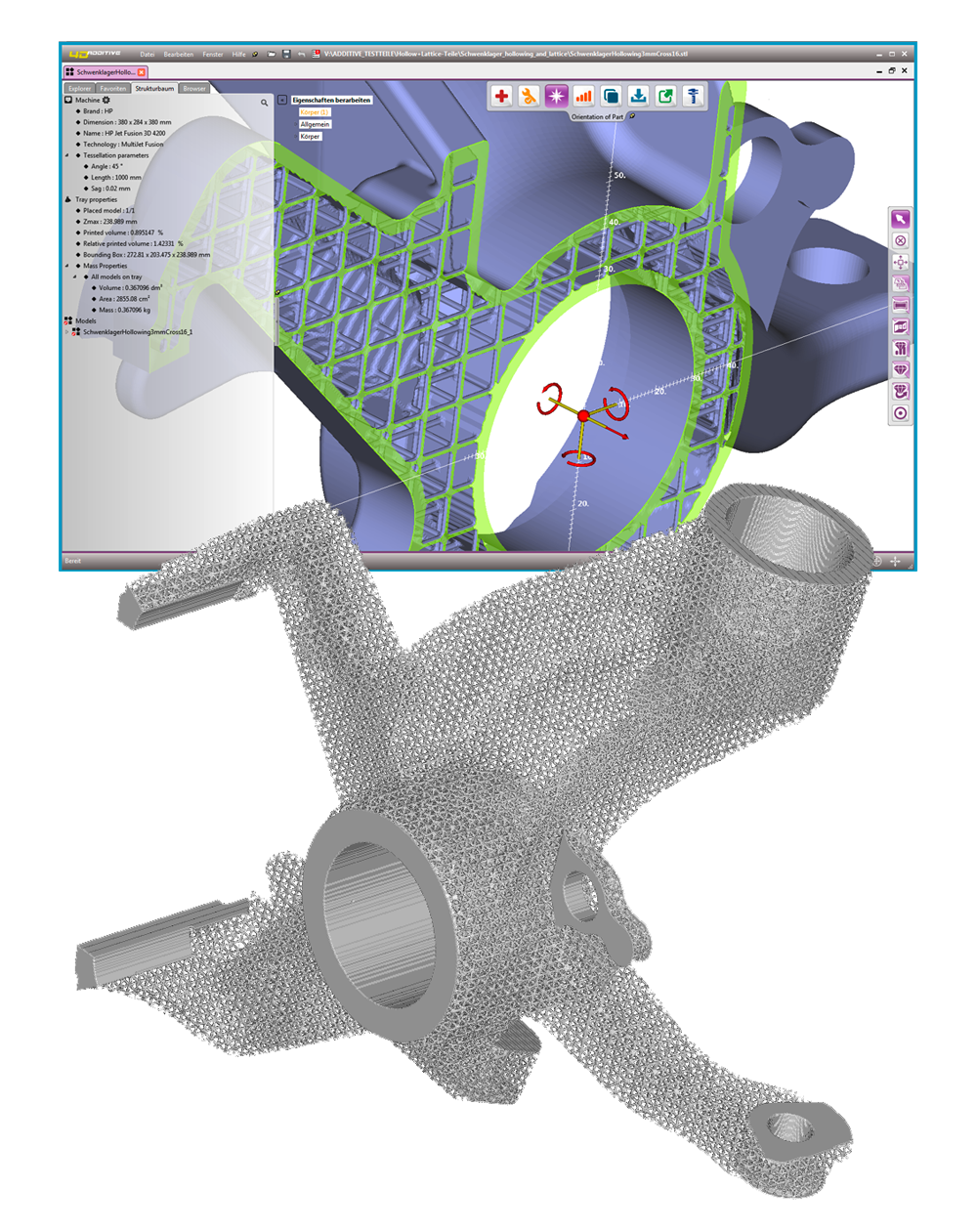

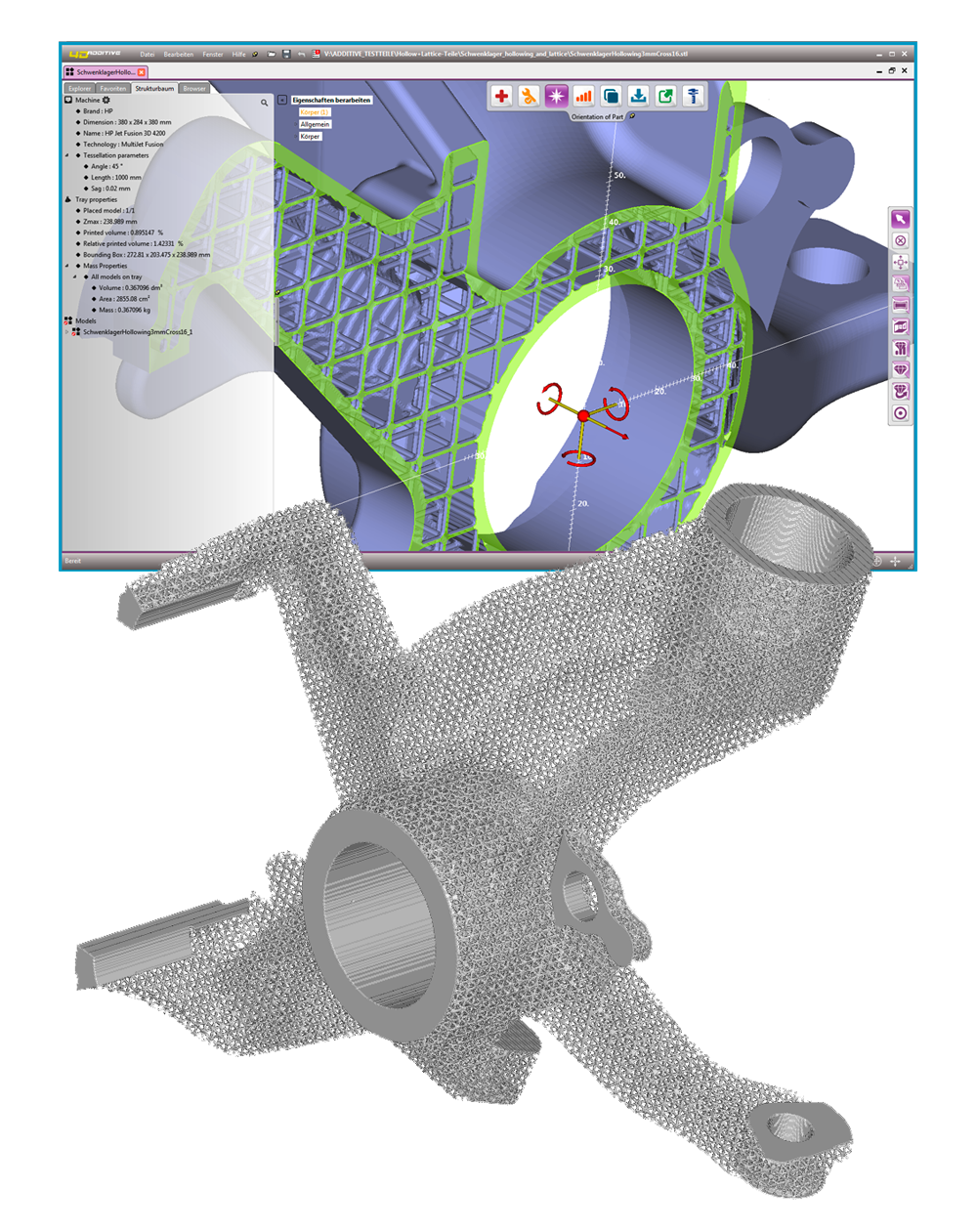

Additive Manufacturing, which perfectly embodies the philosophy of the virtual 3D model that is sent

directly to the 3D printer without any intermediate steps.

3D printing aka Additive Manufacturing (AM) is

changing and revolutionizing the industrial production technology of tomorrow, because products are

materialized exactly where they are needed in terms of time and space.

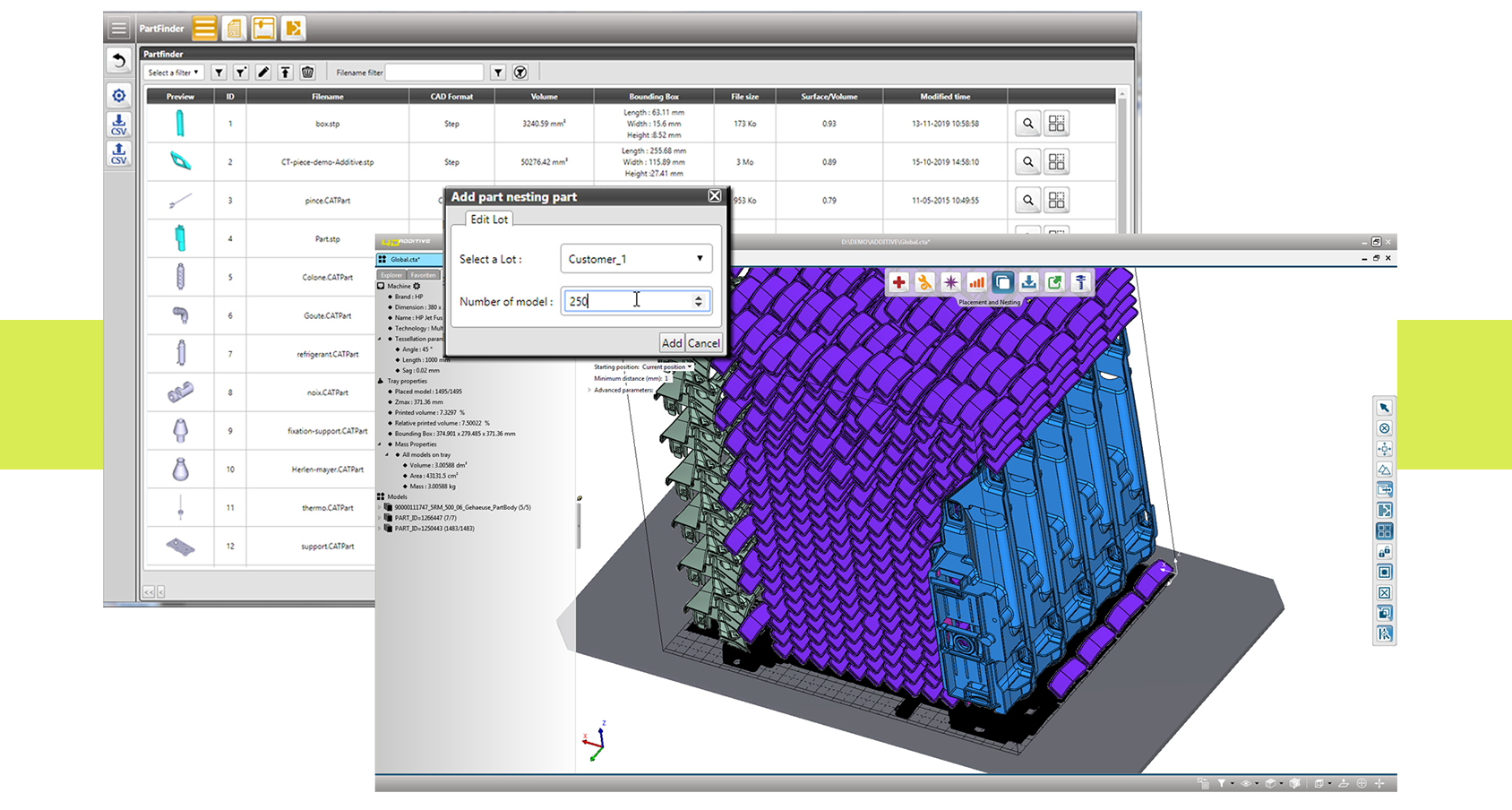

Simplified machine loading

With the latest version of the 3D printing software 4D_Additive, CoreTechnologie introduces a data

management concept for automated Additive Manufacturing. Here, the CAD models stored in the system's own

database are simply ordered and sent directly to the printer. The arrangement and orientation of the

components, the so-called nesting, takes place automatically and does not require any 3D printing-specific

know-how on the part of the user. This significantly simplifies and accelerates the manual process of

machine loading, which was still time-consuming up to now.