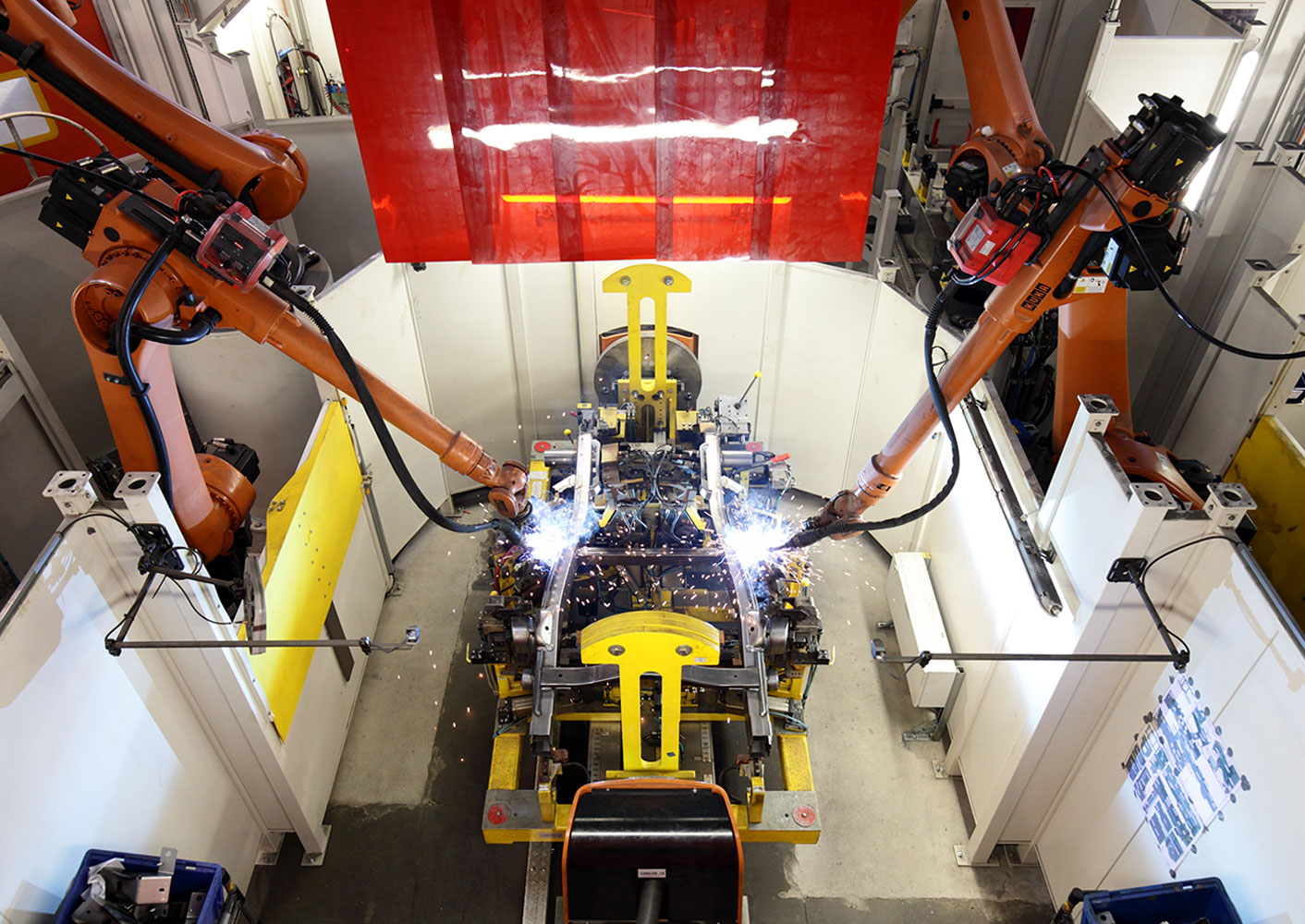

Fully automatic production line

A new era in frame manufacturing at MAGNA Presstec

Since 1979 it has been blazing a trail through woods and fields, mud, gravel and snow: the Mercedes

G-Class.

To

make this feasible, the manufacturer uses particularly stable ladder frames. These frames are built at

MAGNA

Presstec in the Austrian town of Lebring near Graz. Since 2017, production of the facelift model has

been

running fully automatically on a line from KUKA. Specialists from the two companies collaborated closely

to

resolve various challenges, including the particular geometry of the production shop and the size and

weight

of

the components.