Fast format change with IO-Link

In Bäretswil in the Swiss canton of Zurich Combitool AG – a division of PackSys Global – develops and

produces innovative solutions for manufacturing plastic and laminate tubes. To realize the new machine

generation of the BLM Laminat Body Maker, the development engineers at Combitool set ambitious goals for

themselves. The system should not only be resource friendly, but also significantly increase machine

availability and productivity by drastically reducing setup and startup time. The use of intelligent sensors with IO-Link from Balluff made a significant contribution in this regard.

In analyzing the optimization potential, it was the complicated, time-consuming setup and adjustment process of

the photoelectric contrast sensor used for print mark detection that stood out especially. The print mark,

sometimes in the form of an inconspicuous line on the back side of the tube, is used during the production

process for precise orientation of the tube regardless of its shape. Later, when the tube is filled, closed,

sealed and packed, the print mark serves as a reference for the tube orientation, so that the tubes filled with

high-value face creams sit in the exact same orientation on the drugstore shelf and have a uniform, harmonious

appearance.

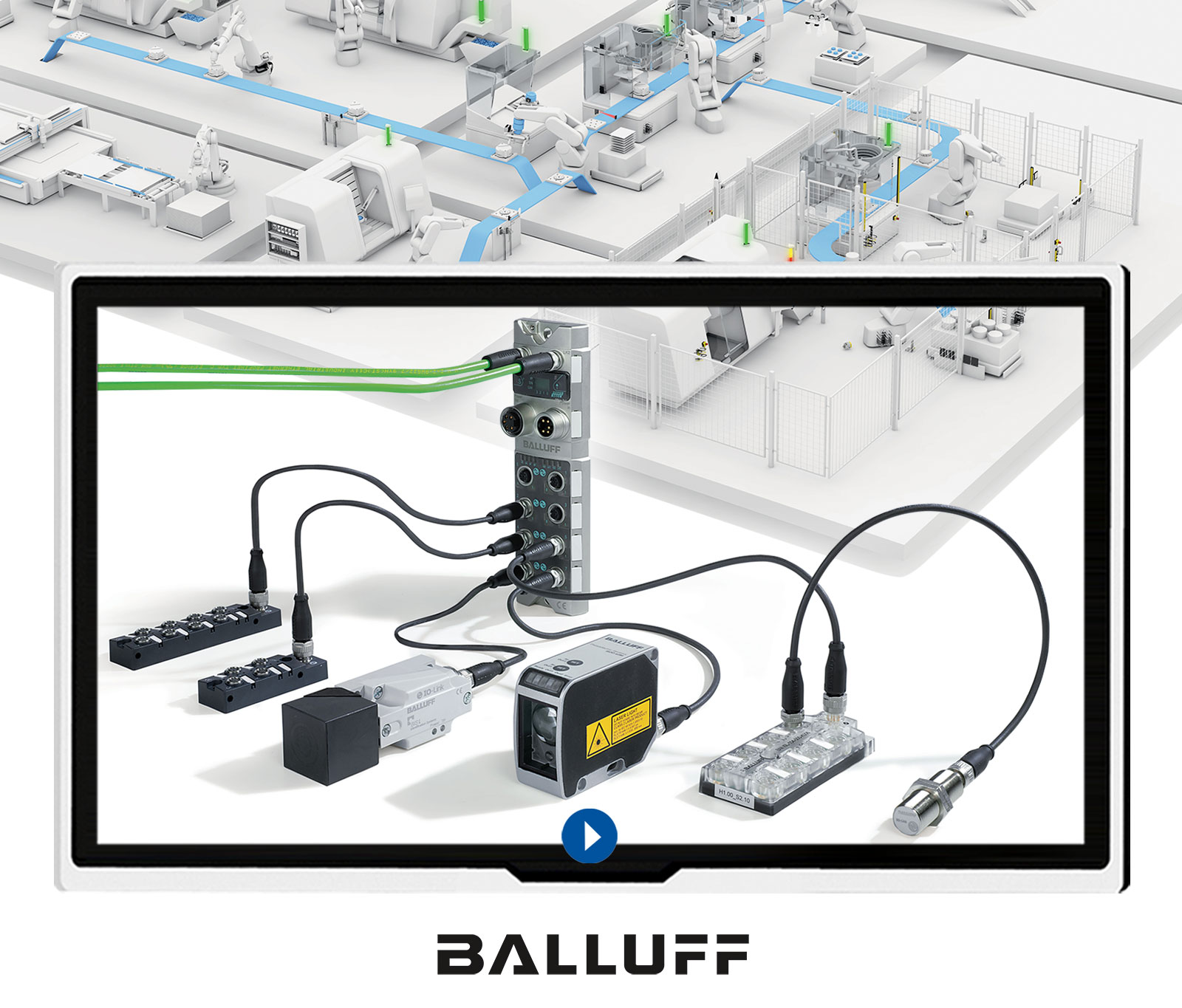

IO-Link process devices can be employed as plug-and-play using an IO-Link master in integrated system concepts. Additional information such as the device identity and diagnostic data, but also including parameter data, are then simple to transmit.

The latter are needed for example when a size or recipe change needs to be performed on-the-fly for flexible lot sizes.

The particular benefit: all communication tasks require no more than a standard, unshielded 3-conductor cable with M12 connector for digital point-to-point connection.

Print mark sensor with potential for improvement

The previous setting procedure for the existing print mark sensor using keys directly on the sensor and in teach-in mode proved to be time-consuming and only rarely repeatable, so that the settings always had to be started over from the beginning, even if the same configuration had already been used many times. The remedy here was to use a sensor with IO‑Link interface.IO-Link process devices can be employed as plug-and-play using an IO-Link master in integrated system concepts. Additional information such as the device identity and diagnostic data, but also including parameter data, are then simple to transmit.

The latter are needed for example when a size or recipe change needs to be performed on-the-fly for flexible lot sizes.

The particular benefit: all communication tasks require no more than a standard, unshielded 3-conductor cable with M12 connector for digital point-to-point connection.

The "BLM Laminat Body Maker" profits from the use of modern IO‑Link sensors. The BTL6 profile magnetostrictive transducer ensures the optimal level of the film accumulator while feeding the film

×

![]()