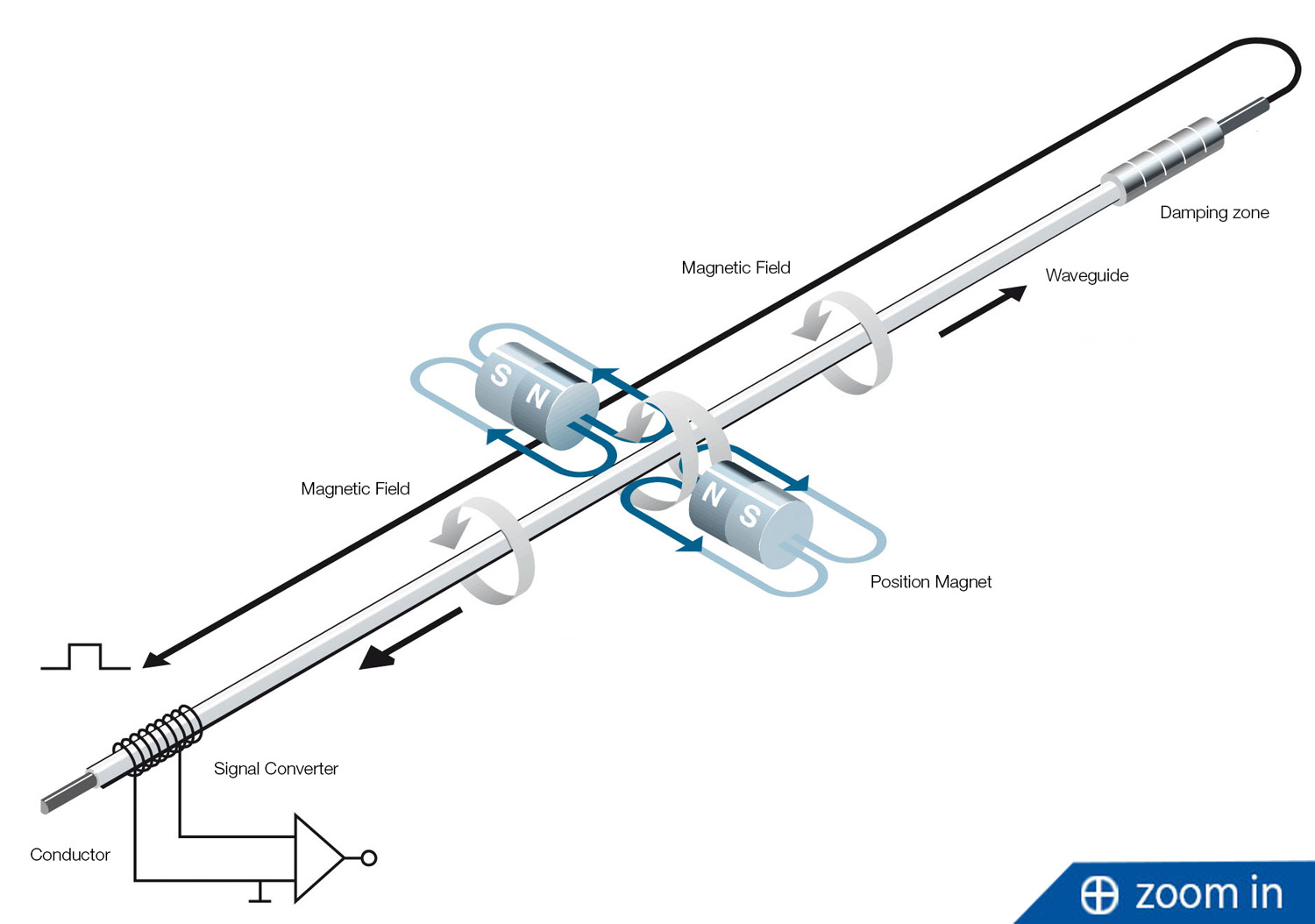

How magnetostrictive sensors work

Magnetostrictive sensors are characterized by high reliability and precision in position and speed

measurement. They can be installed in hermetically sealed housings as they transmit the current position

information via magnetic fields contactlessly through the housing wall to the internal magnetostrictive

sensor element. Thanks to their high resistance to shock and vibration, they are suitable for heavy

machinery and plant construction.

The sensor element – the waveguide – is a metallic tube made of magnetostrictive material into which a copper conductor is threaded.

The sensor element – the waveguide – is a metallic tube made of magnetostrictive material into which a copper conductor is threaded.

Design principle of magnetostrictive sensors

During the measuring process, the excitation current pulse induces a circular

magnetic field, which is bundled thanks to the soft magnetic properties of the waveguide.

A permanent magnet (in the illustration called position magnet) which is mounted on the moving component to

be measured, serves as a passive position sensor. At the measuring point, both magnetic fields overlap at

right angles and deform the waveguide minimally by magnetostriction. The elastic deformation generates a

mechanical wave that propagates to both sides at 2,850 metres per second. The induction coil at one end of

the waveguide converts the mechanical wave into a current pulse so that the evaluation electronics can

precisely determine the position on the basis of the wave propagation time. At the other end of the

waveguide, a damping element prevents disturbing reflections of the mechanical wave.

▪

Author: Dr. Detlef Zienert, Press Relations Manager, Balluff GmbH