Of all the environments for electronic equipment, mobile ones are perhaps the most

severe. But it is a growing market across all sectors, from railways to materials

handling equipment, EVs to e-scooters, and much more. In rail rolling stock applications

particularly, automation is being increasingly incorporated for safety and efficiency

savings, along with convenience features such as data connectivity and intelligent

signage. All of this must operate reliably in the typical rail environment of high

pollution, shock, and vibration with power most often from the traditional DC rail

of 110 VDC nominal, with some global variations down to 24 VDC.

The standard that

typically applies is EN 50155, currently version July 2021, which defines the electrical

and physical environment and technical construction features, reliability, maintenance,

service life, documentation, and testing.

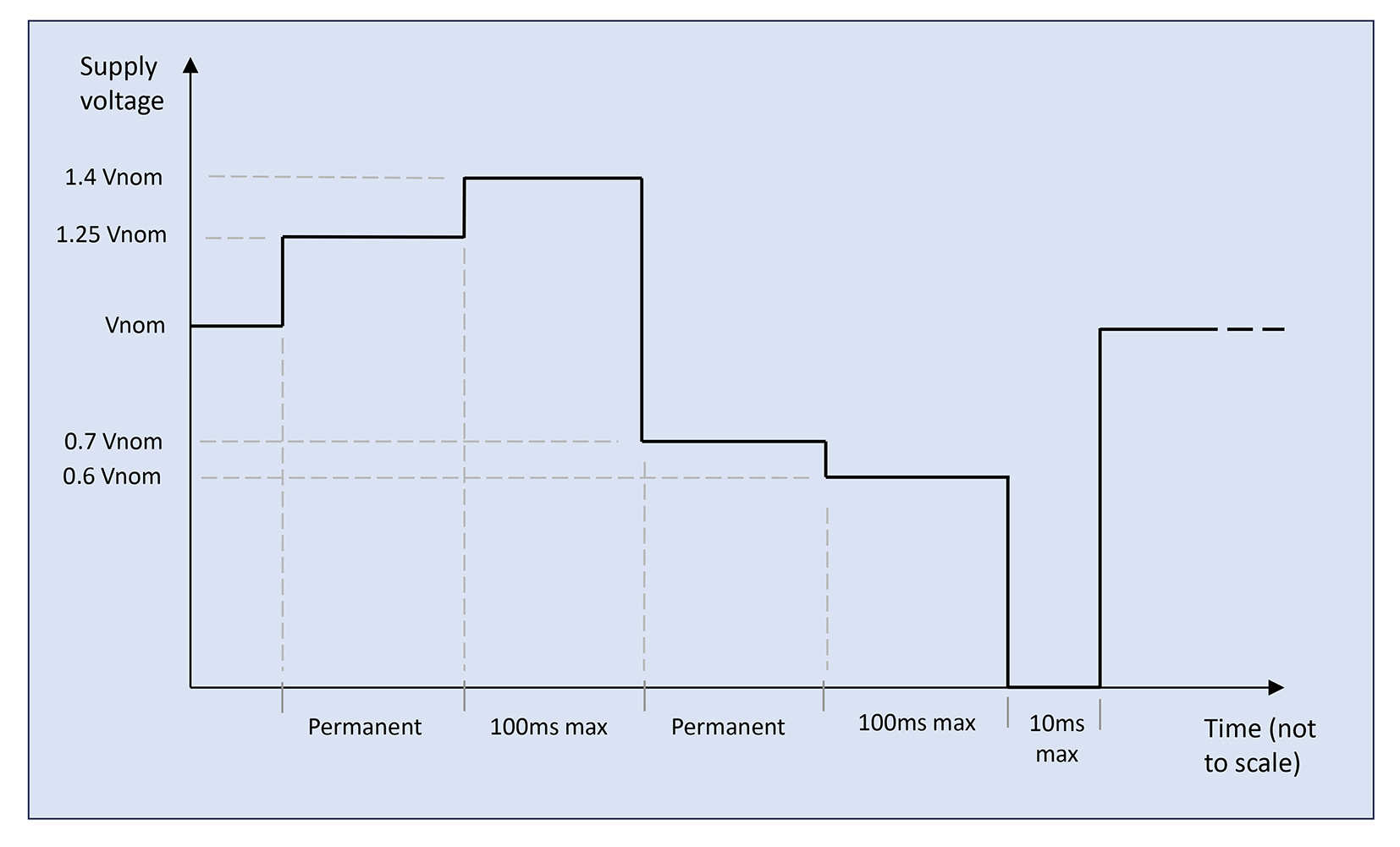

Rail supply voltages vary widely

As well as meeting environmental, isolation, and EMC specifications, the power supply modules

that convert the DC supply to a clean rail for the sensitive electronics must cope with

wide variations in input voltage, which also has superimposed surges, dips, and drop-outs.

Figure 1 shows the levels defined in EN 50155 for no impact on performance.