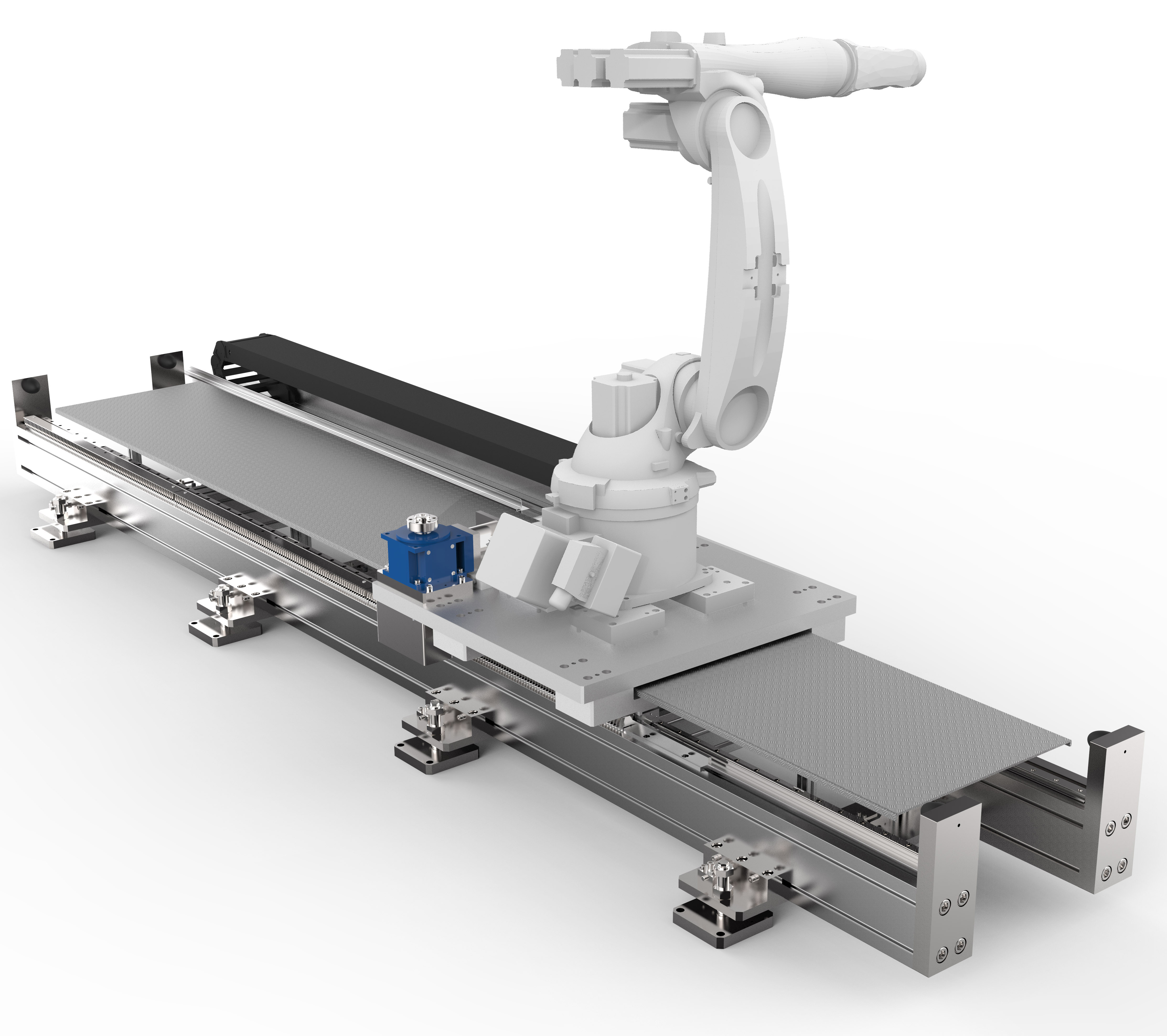

If it is mobilised with a seventh axis, a single robot can perform palletizing tasks at several

different locations

Seventh Axis for robots

The concept of the seventh axis provides robot applications with an increased motion range. With the

Seventh Axis system from the Actuator System Line Rollon offers a practical solution for this task.

The shuttle system moves robots on a ground-level linear axis made of aluminum profiles very dynamically over

long distances. It allows robots to perform tasks in multiple locations to achieve better utilization. Due to

the low dead weight of the Seventh Axis system, only low ceiling loads occur, so that it can also be used

without problems in production halls with basements. Seventh Axis is suitable for carrying out palletizing

tasks, operating machine tools, bending and handling sheet metal as well as welding and painting work or for

gluing components.