Linear servomotors from NPM have high precision and are free of

cogging

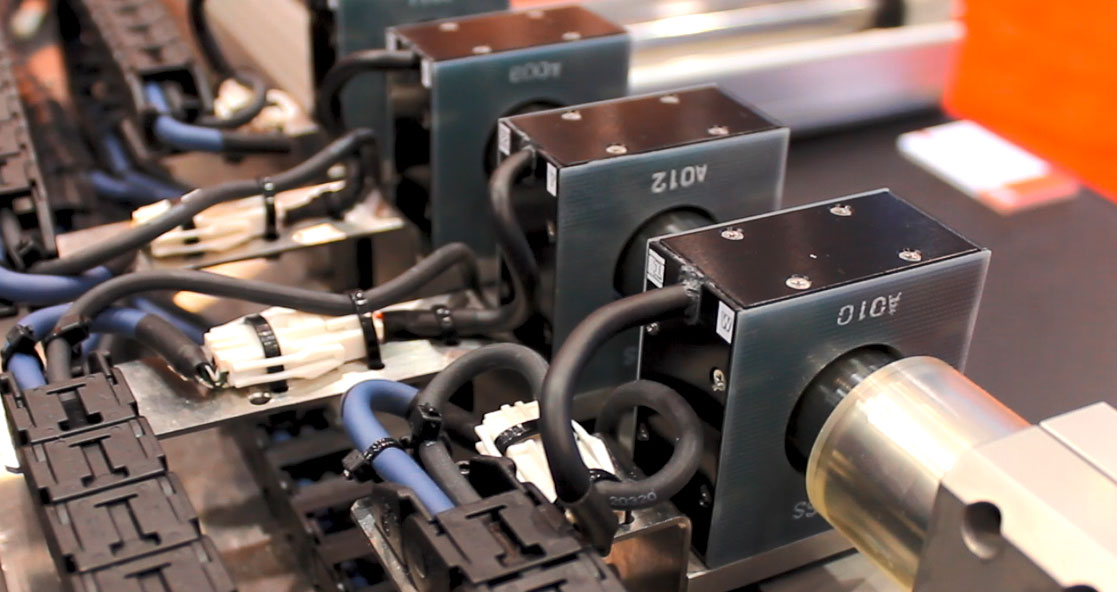

The NPM linear servomotors are suitable for applications requiring a high-precision direct-driven motor. They

are ideal not only for complex motion in confined spaces, but also for parallel drive systems with, for

example, two or more parallel linear motors controlled by a single drive controller.

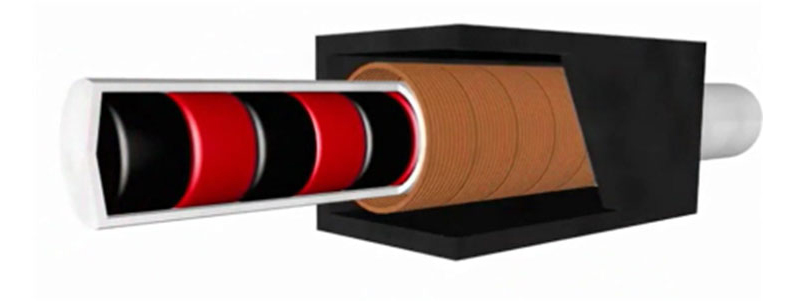

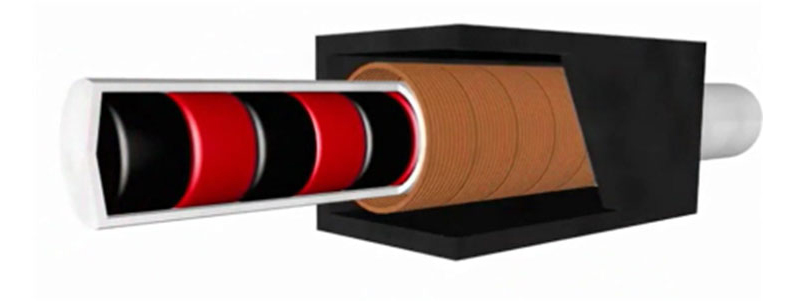

There is no iron in either the shaft or the coil (forcer), which ensures high precision and no cogging. The

coils themselves form the core and thus give the motor the necessary stiffness. These linear servomotors are

contactless. Since the coil wraps completely around the magnets, the magnetic flux is used effectively. This

allows a large annular nominal air gap of 0.5 to 5 mm. This air gap is non-critical, meaning there is no

variation in force. The linear shaft motor does not require lubrication and does not show any power drop due

to wear and aging.

DThe play between shaft and driver eliminates the need for settings such as guide

positioning or concentric settings. Dust and noise, as with ball screws and pneumatic systems, do not occur

in the linear servo motor. This is not only beneficial for cleanroom applications, but also helps to improve

the working environment. The linear shaft motor enables a level of precision not achieved by ball-screws and

allows you to drastically improve the yield of high precision processes, which are limited by other linear

mechanism. The precision of repetitive positioning is dependent on the resolution of the linear encoder.

Complex movements

within limited spaces

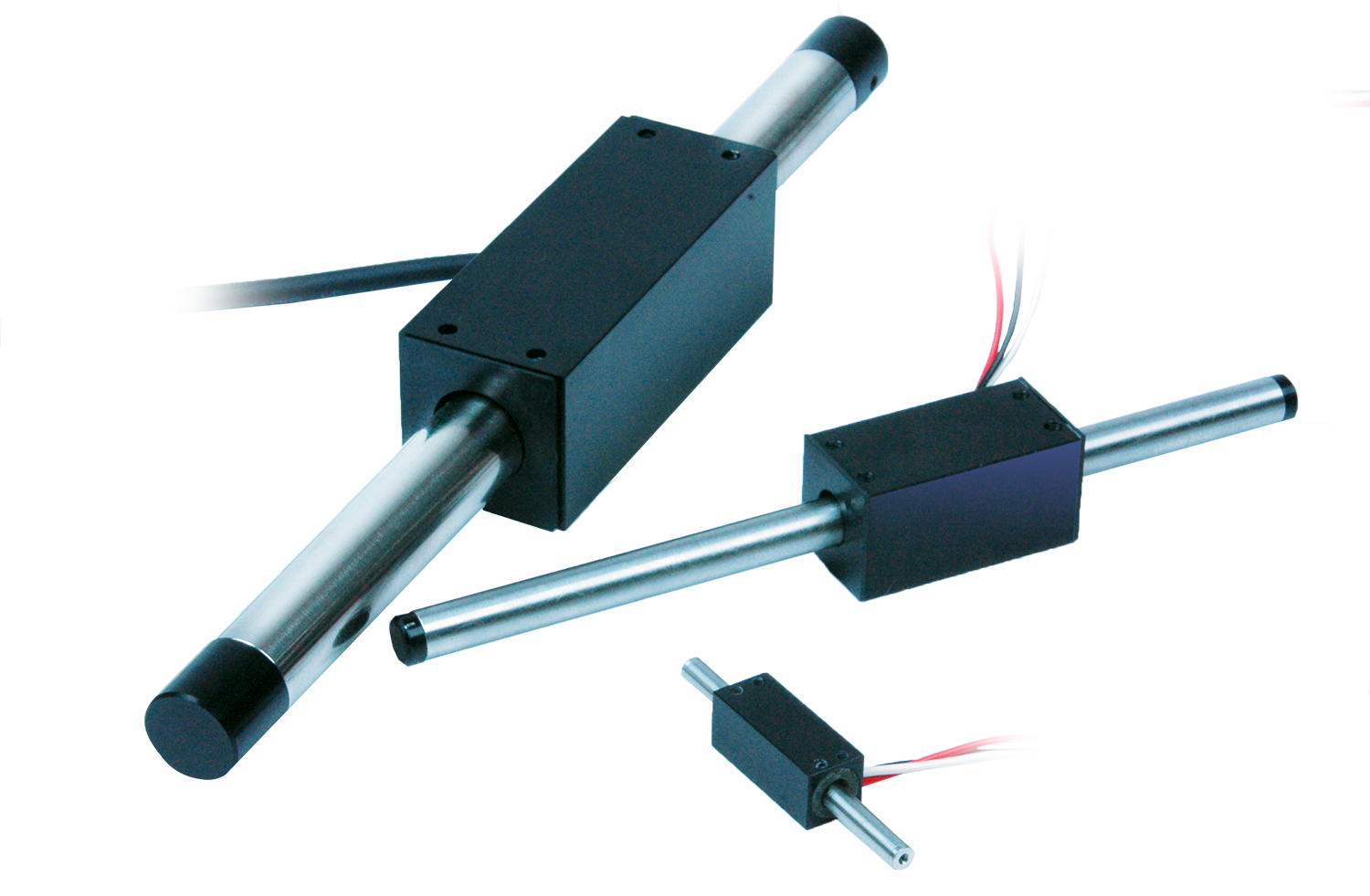

The SS series of linear servomotors are an economical solution for applications that perform multiple

complex movements under confined spaces with high reproducibility.

The linear motor has the smallest available runner (Forcer) with a diameter of 25 mm and a length of 30

mm. It has a higher thrust compared with other standard motors in the market. The maximum usable travel

distance on a shaft is larger than two meters. The compact Forcer enables a high-density implementation.

Upon customer request, the servo motors can be manufactured in the desired length.

Linear servo motor

Linear servo motor