The automation at the beginning and end of a line depends on how the workpieces are fed and stored. If the

delivery just involves removing a single layer of goods from a pallet, contour or feature recognition is

sufficient for enabling automated gripping and transfer to the follow-up process. If the workpieces are in

several layers, such as stacked blister packs or tablet packages, the robot requires a 2½D or 3D system. In

the former case, the third dimension is extrapolated using contour distances or gray-scale values. For a

real 3D process, the system measures using points in space.

Flexible loading and unloading

The same is true of positioning. The more accurately the workpiece has to be placed, the more demanding the

requirements put on the vision system.

Placement on a conveyor belt is simple; positioning within a machine

tool is challenging. The more flexibility required for loading and unloading a workpiece (into and out of

the machine), the more complex the system.

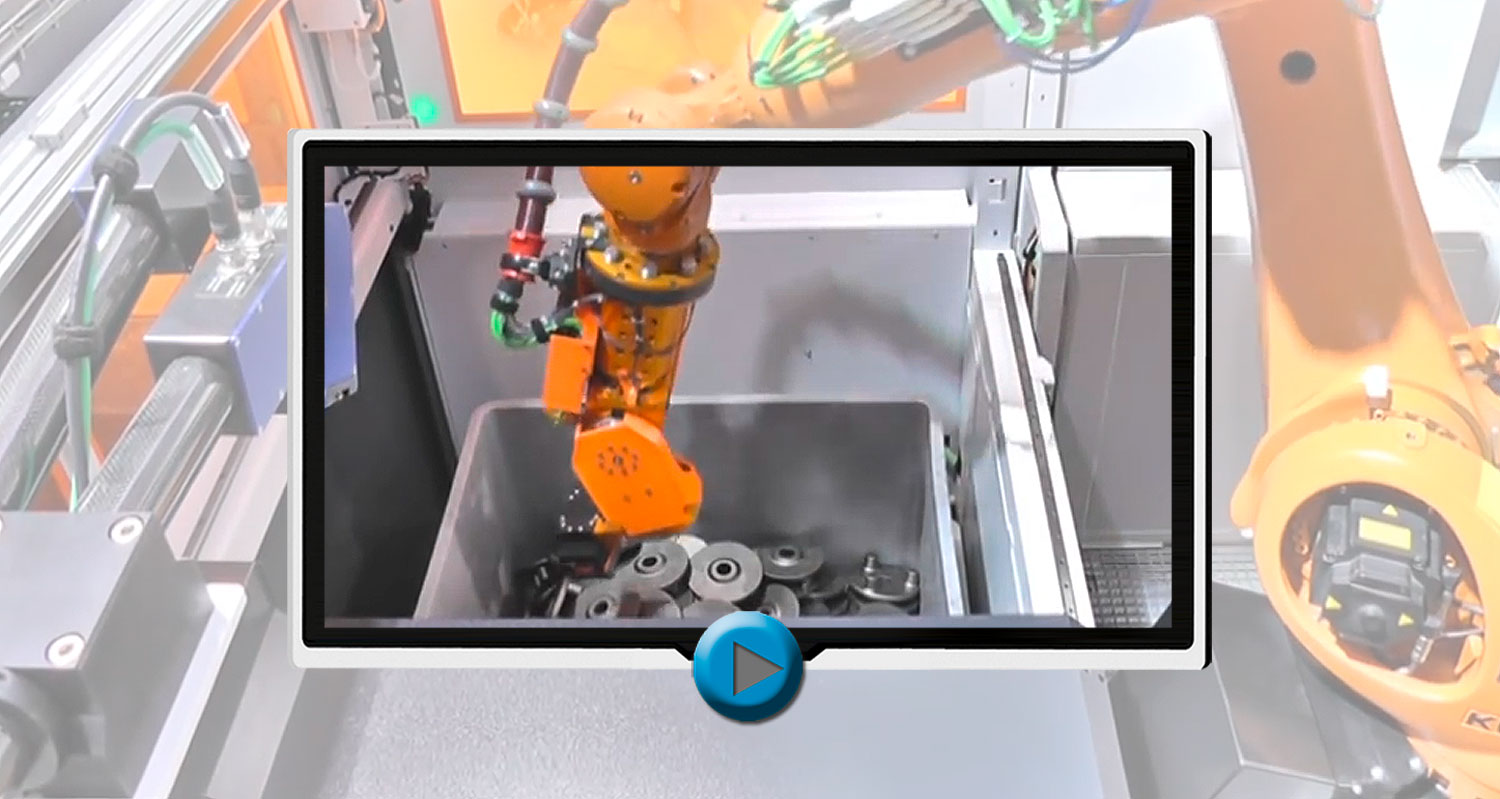

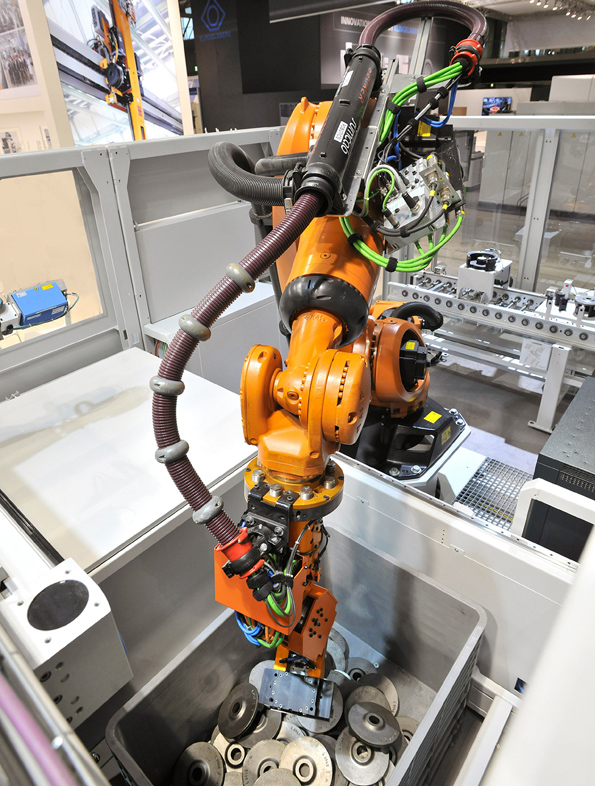

A robot removes unsorted parts from a deep box