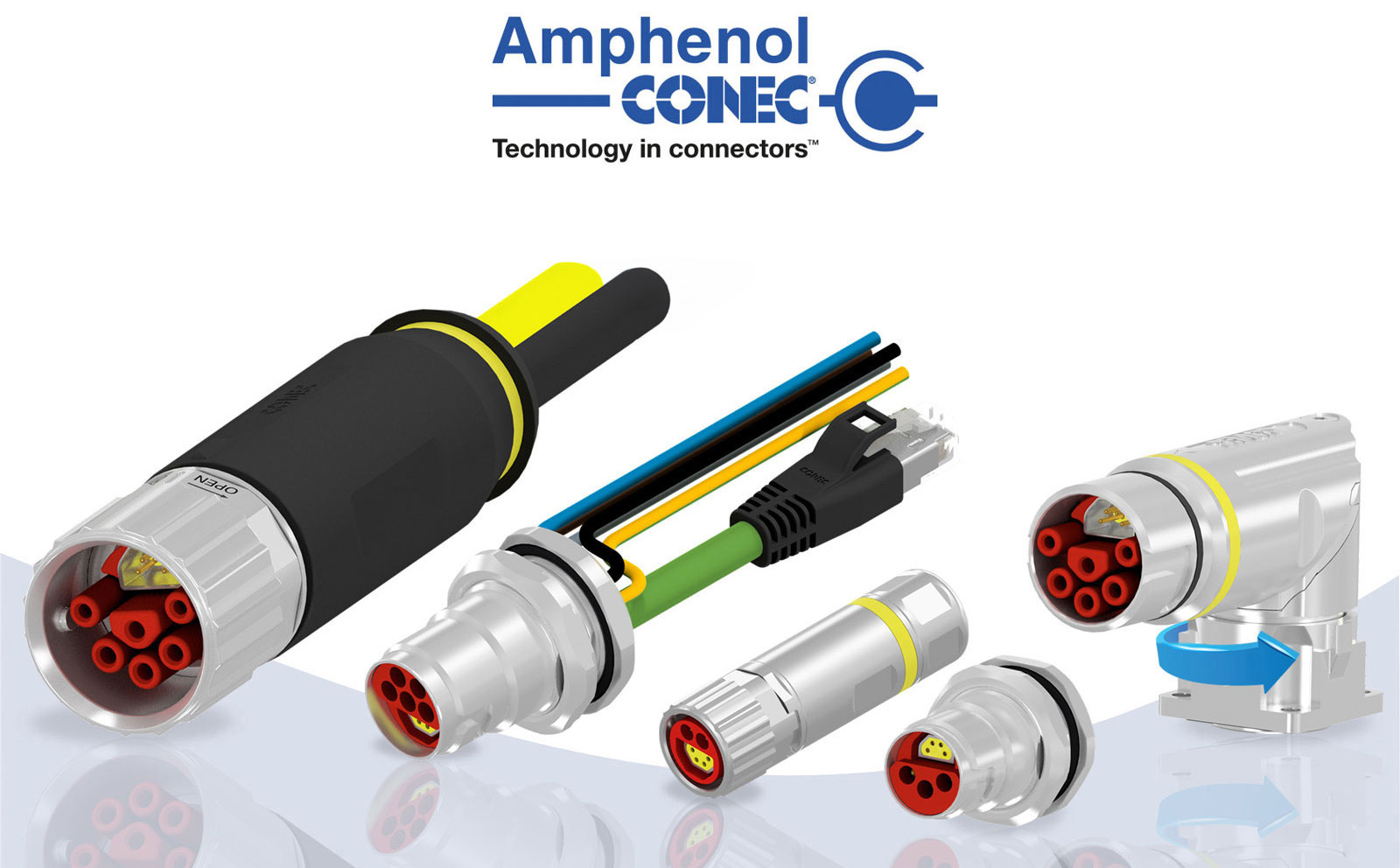

One-Cable Hybrid Connectors

Power supply and data transmission in one connector

Conventional cabling of electric motors, servo drives or linear units is often very complex. Separate cables

are used for power, data and signal transmission for different tasks. This wiring concept is not only

expensive, but also difficult to maintain. It also takes up a lot of space.

CONEC hybrid connectors excel with shorter assembly times and reduced weight on the end device (for example, a motor). With various sizes (B12, B17, B23, B40), CONEC offers the suitable hybrid connector for nearly every power class, whether it is a small DC drive or a powerful servo drive.

Strand cross-sections up to AWG22/0.34 mm² and strand diameters up to 1.6 mm can be easily assembled.

The continuous trapezoidal shielding sleeves of the data element provide 360-degree shielding over the entire length of the connection. The four sizes are complemented by a number of power contacts tailored to the respective application.

CONEC hybrid connectors will be certified in the future according to IEC standard 61076-2-118.

CONEC hybrid connectors excel with shorter assembly times and reduced weight on the end device (for example, a motor). With various sizes (B12, B17, B23, B40), CONEC offers the suitable hybrid connector for nearly every power class, whether it is a small DC drive or a powerful servo drive.

Four-pole centerpiece with three data module variants

The four sizes of CONEC Hybrid Connectors all have the same centerpiece: a separately shielded, four-pin data element for transmitting Industrial Ethernet. In addition to the four-pole data element with Ethernet/Ethercat protocol, it is also possible to equip the data element as a blind module – for use as a pure power connector or with a two-pole insert for two-wire BUS protocols. The modular design of the connectors offers advantages in terms of both assembly and installation.Strand cross-sections up to AWG22/0.34 mm² and strand diameters up to 1.6 mm can be easily assembled.

The continuous trapezoidal shielding sleeves of the data element provide 360-degree shielding over the entire length of the connection. The four sizes are complemented by a number of power contacts tailored to the respective application.

CONEC hybrid connectors will be certified in the future according to IEC standard 61076-2-118.