New single-axis

vibration sensor monitors drives

Turck expands condition monitoring sensor portfolio

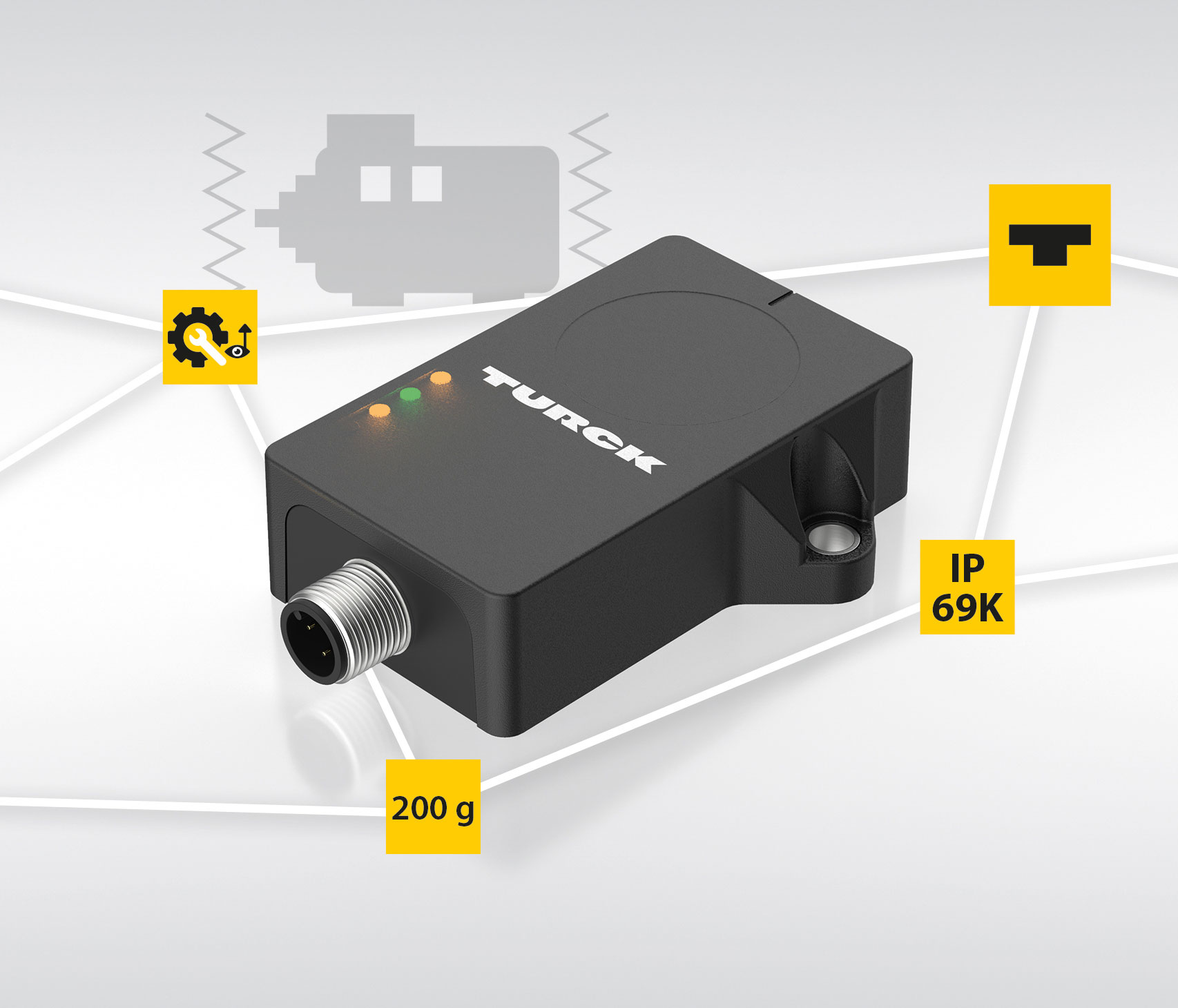

Turck's CMVT-M8T in a compact stainless-steel housing uses vibration measurement to monitor the condition of motors and drives. With single-axis measurement, easy installation in the service bore via M8 screw-in thread including mounting adapter up to M30 and three selectable output signals, the sensor ensures precise vibration monitoring with minimum installation effort.

The CMVT-M8T detects vibrations along one axis and is therefore suitable for typical

applications on drives, pumps or fans where the main direction of vibration is

orthogonal to the axis of rotation. With IO-Link,

PNP switching and 4...20 mA analog outputs, the condition monitoring sensor

can be used universally and thus effectively reduces inventory costs.

The measuring accuracy is ±0.5 percent at 159.2 Hz. The sensor also provides

peak acceleration values in addition to effective values (RMS).

Integration into existing systems also possible

The device can also be commissioned without a connection to a controller using

the Vibration Monitor app in the Turck Automation Suite (TAS) or via an IO-Link master

with a web server.

In combination with a warning light, autonomous condition

monitoring systems can easily be set up without a controller,

which is particularly useful in existing systems.

The sensor complies with ISO standard 10816-3 for the entry of critical vibration values.

Condition monitoring portfolio grows

The new single-axis sensor is the fourth sensor type that Turck has developed specifically

for easy-to-use and retrofittable condition monitoring applications.

It complements the existing range consisting of the CMVT-QR20 three-axis

vibration/temperature sensor, the CMMT magnetic field/temperature sensor

and the CMTH for humidity and temperature measurements.

Three-axis vibration/temperature sensor CMVT-QR20

The CMVT-QR20 detects vibration on three axes and evaluates them internally.

It outputs a warning signal directly if the set limit values are exceeded –

either via IO-Link or as a switching signal.

Vibration and temperature are the key characteristic values

for detecting machine faults early on, such as those caused by the

imbalance of rotating parts.

Magnetic field/temperature

sensor CMMT

With the CMMT, the combined measurement of magnetic field and

temperature enables simple detection of faults on motors or in processes with magnetic components.

In addition, the new sensor also opens up applications that were previously impossible,

such as the non-contact detection of the rotation and movement of metal objects

without visual contact.

With an IO-Link output and two switching outputs, the CMVT-QR20 is ideal for condition monitoring in existing or new plants

Turck's CMMT magnetic field and temperature sensor detects magnetic field changes across three axes and calculates the vector sum of the measurements