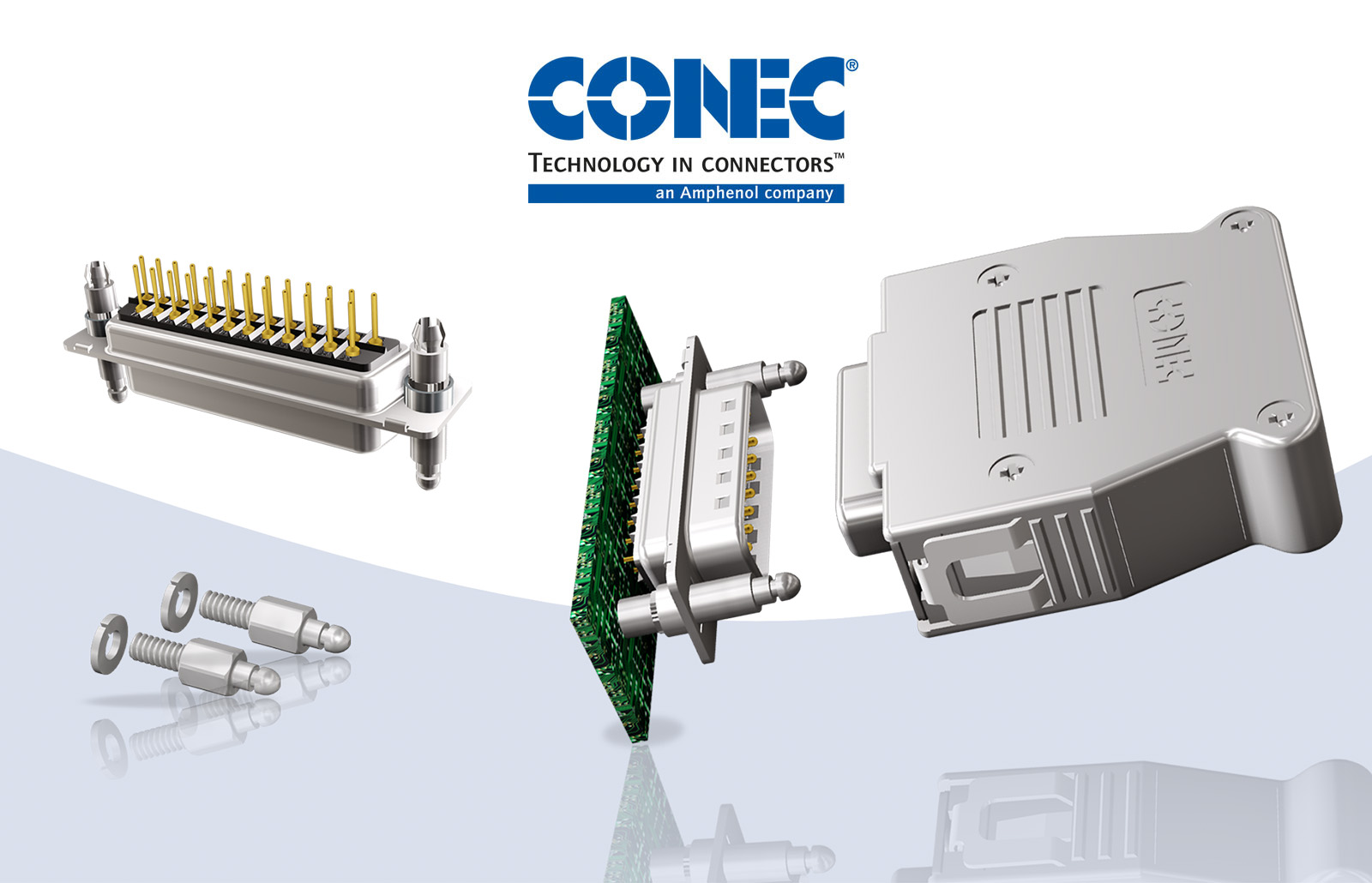

CONEC SnapLock Hoods and

D-SUB Connectors

CONEC SnapLock is the ideal solution for anyone looking for a D-SUB quick-locking

system with fast locking and unlocking without additional tools, which also

enables locking with an audible and tangible "click", even at poorly visible device interfaces.

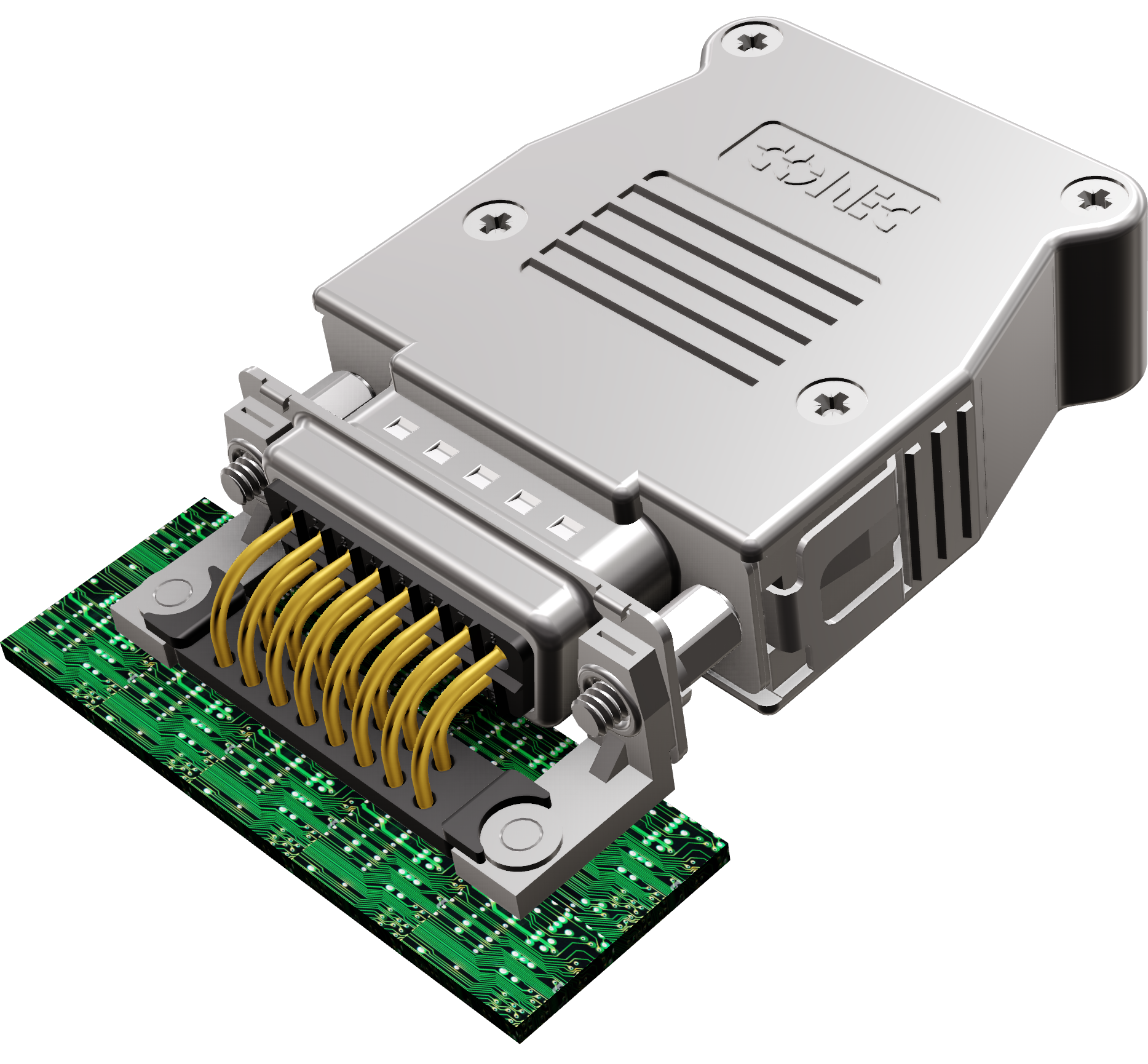

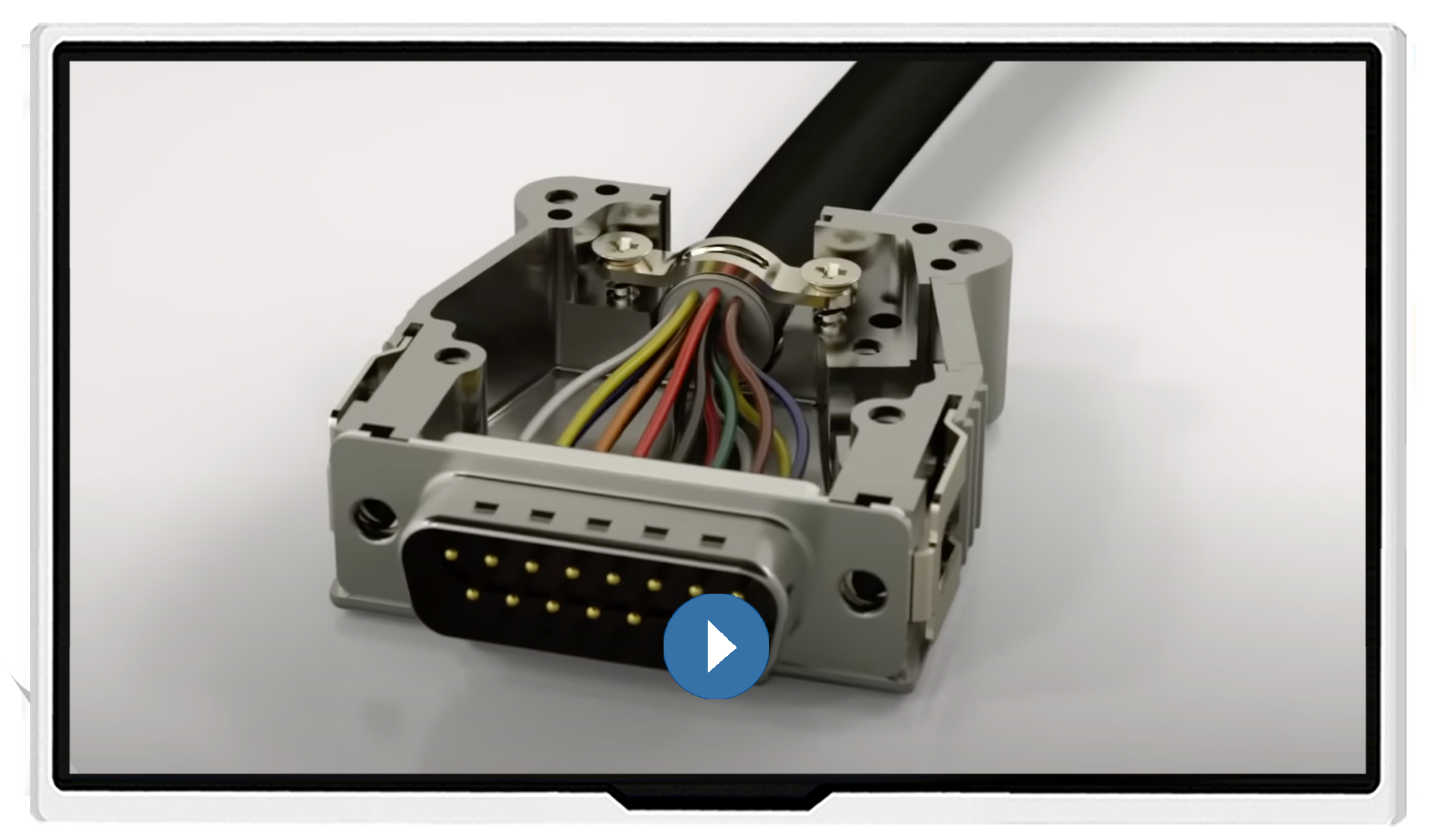

The CONEC SnapLock locking system consists of D-SUB connectors and

D-SUB hoods allowing quick and safe locking without any additional

screwing. A spring-loaded clip integrated in the hood locks in place with

the locking bolt mounted to the mating connector and ensures a quick and

safe connection. The locking bolt for the connector is available in two variants.

One variant is firmly integrated in the connector, for example with a standard thread insert.

One variant is firmly integrated in the connector, for example with a standard thread insert.