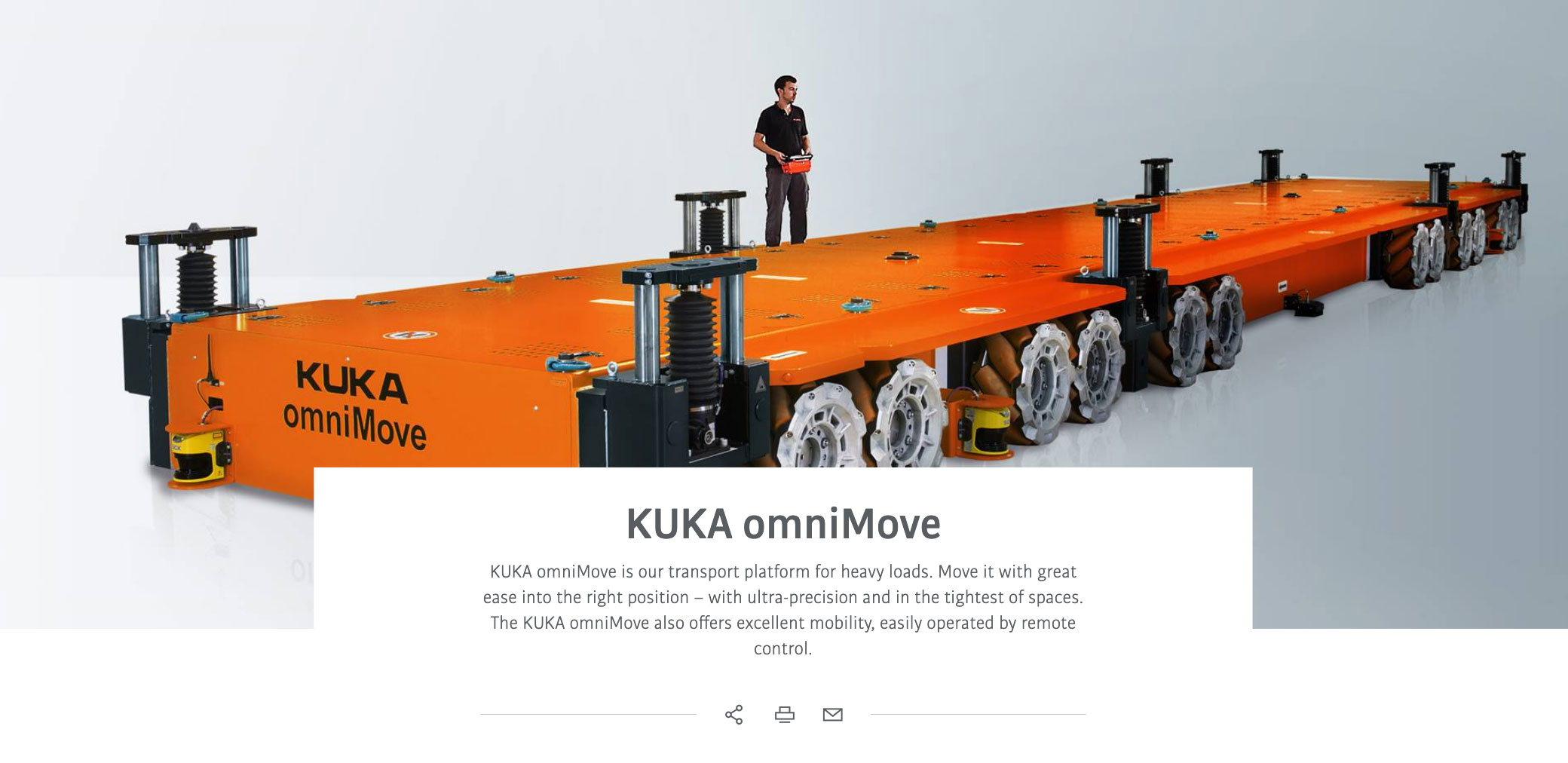

The aluminum plates, measuring up to 12 m in

length and weighing up to 8.5 tonnes, lie waiting at goods receiving. There is a QR code attached to the

underside of the carrier on which the plates are stacked. Equipped with a camera, the omniMove identifies the

aluminum plates assigned to it on the basis of the QR code. The omniMove collects them by moving underneath the

stack with millimeter precision. The lift spindles are extended and the omniMove lifts the carrier complete with

the aluminum plates. Laden with the XXL package, it navigates autonomously through the production shop and

unloads the plates at the pre-determined machining station. As soon as the finishing process has been completed,

the heavy-duty platform fetches the aluminum plates again and transports them to the next station.

Automation achieves

AMAG is highly satisfied with the omniMove. The automation of the intralogistics system has brought many

advantages for the company. Compared with a crane or fork lift truck solution, work can be performed much more

flexibly, faster and safer with the omniMove. Use of the transport frame has also considerably reduced packaging

requirements. In three-shift operation, the finishing facilities are supplied with aluminum plates around the

clock by the two heavy-duty transporters.

▪

Automation achieves

the desired success

AMAG is highly satisfied with the omniMove. The automation of the intralogistics system has brought many

advantages for the company. Compared with a crane or fork lift truck solution, work can be performed much more

flexibly, faster and safer with the omniMove. Use of the transport frame has also considerably reduced packaging

requirements. In three-shift operation, the finishing facilities are supplied with aluminum plates around the

clock by the two heavy-duty transporters.

▪ Author: Sebastian Schuster, Global PR & Content Manager, Division Industries, KUKA AG

Find out more now!

Siemens:

Siemens: Yamaichi: Y-Circ P Push Pull Circular Connector

Yamaichi: Y-Circ P Push Pull Circular Connector

KUKA:

KUKA:  Kontron: Industrial Panel PCs & Monitors

Kontron: Industrial Panel PCs & Monitors

mb connect line:

mb connect line:  Weidmüller:

Weidmüller: Siemens:

Siemens: Turck:

Turck: