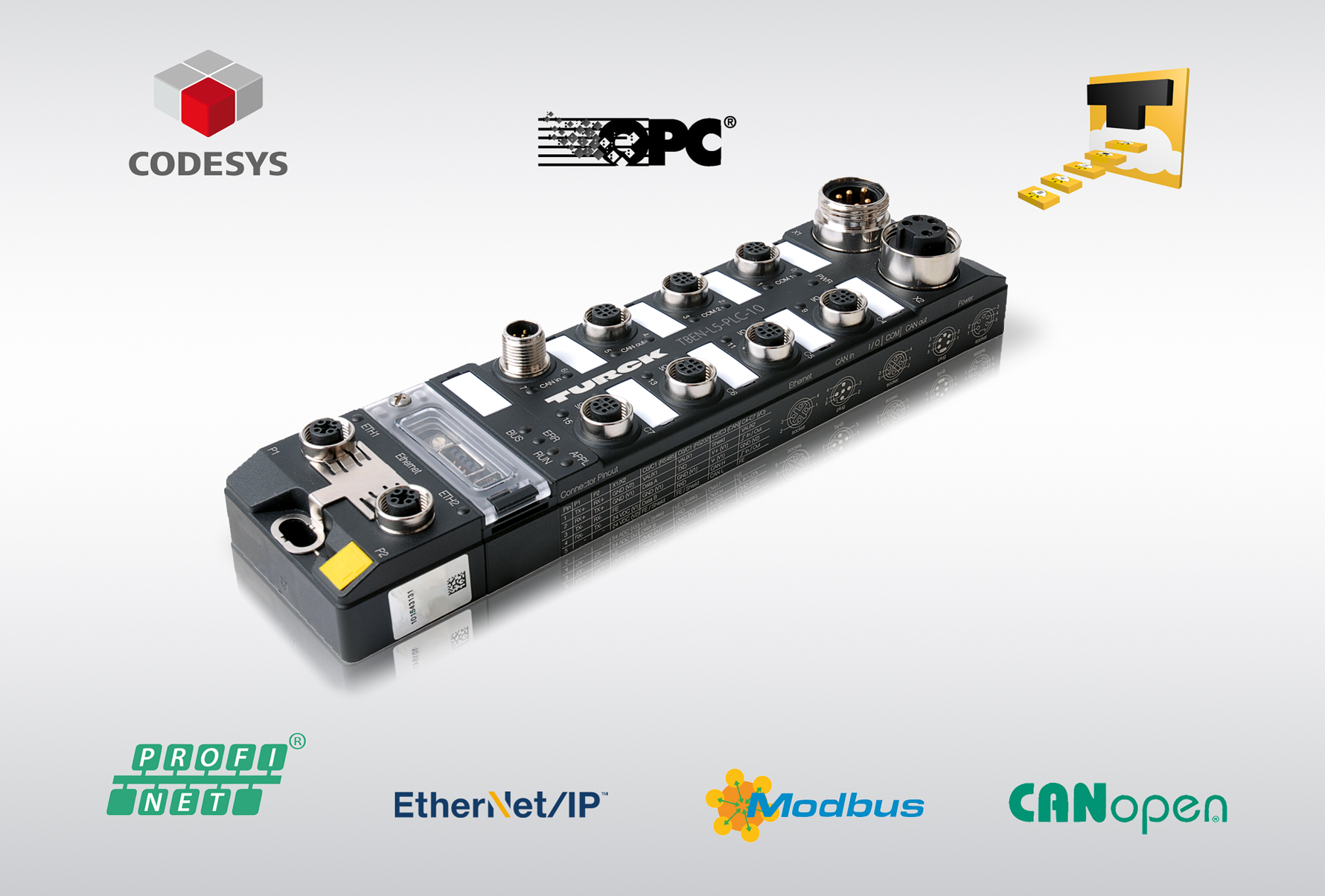

IP67 PLC with Direct Cloud Connection and Multiprotocol Ethernet

Robust control TBEN-L-PLC with integrated Edge Gateway

Turck has presented the TBEN-L PLC as the world's first IP67 controller for industrial applications,

which not only offers an onboard CODESYS PLC but also enables a cloud connection and communication

with different Ethernet protocols at the same time, thanks to its multiprotocol technology.