BOGE stands out from the competition with its innovative new service

package, while also providing added value for its customers

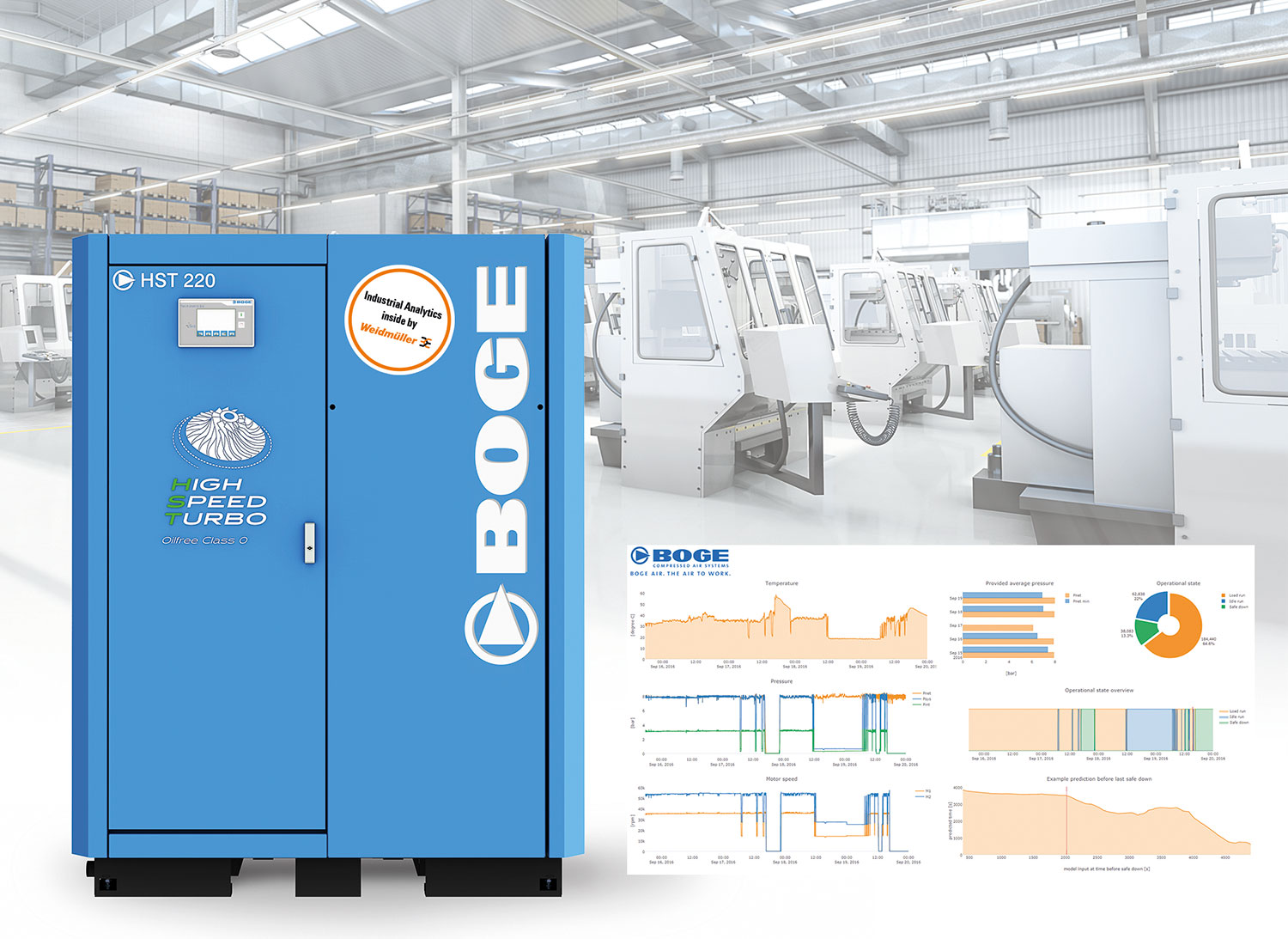

Weidmüller will be presenting a live application of its Industrial Analytics solution at the Hannover Messe in

hall 11, stand B58, using BOGE Compressors as an example. An HST 220 (High Speed Turbo) high-performance

compressor by compressor manufacturer BOGE will be demonstrated here, which uses the Industrial Analytics

software for preventative maintenance from Weidmüller to detect errors and operational anomalies. The highlight

of the live application is the analysis of parameters that can be adjusted directly on the machine. This means

that visitors can adjust the cooling system, for example, in order to simulate engine problems. The analytics

software from Weidmüller quickly detects the adjusted framework conditions and uses a special forecasting

algorithm to indicate the new probability of failure due to the manipulation, and to warn the machine user in

the event of a potential failure. The data from the analytics software is processed offline, directly on the

compressor IPC – data is visualised via a browser display, meaning that it can be viewed on different end

devices at the trade fair stand.

Preventive error avoidance

The new BOGE HST compressors represent a key milestone in the development of class 0 oil-free compressed air

production. The application areas of BOGE HST compressors include the pharmaceutical and food industries,

industrial paint shops and semiconductor production. In all application areas, the consequences of machine

downtime can be catastrophic. Preventative error prevention is a prerequisite for increased process reliability

and optimal energy management for customers. That's why BOGE has been continuing to drive forward its strategy

Compressed Air 4.0 in the areas of service and maintenance.