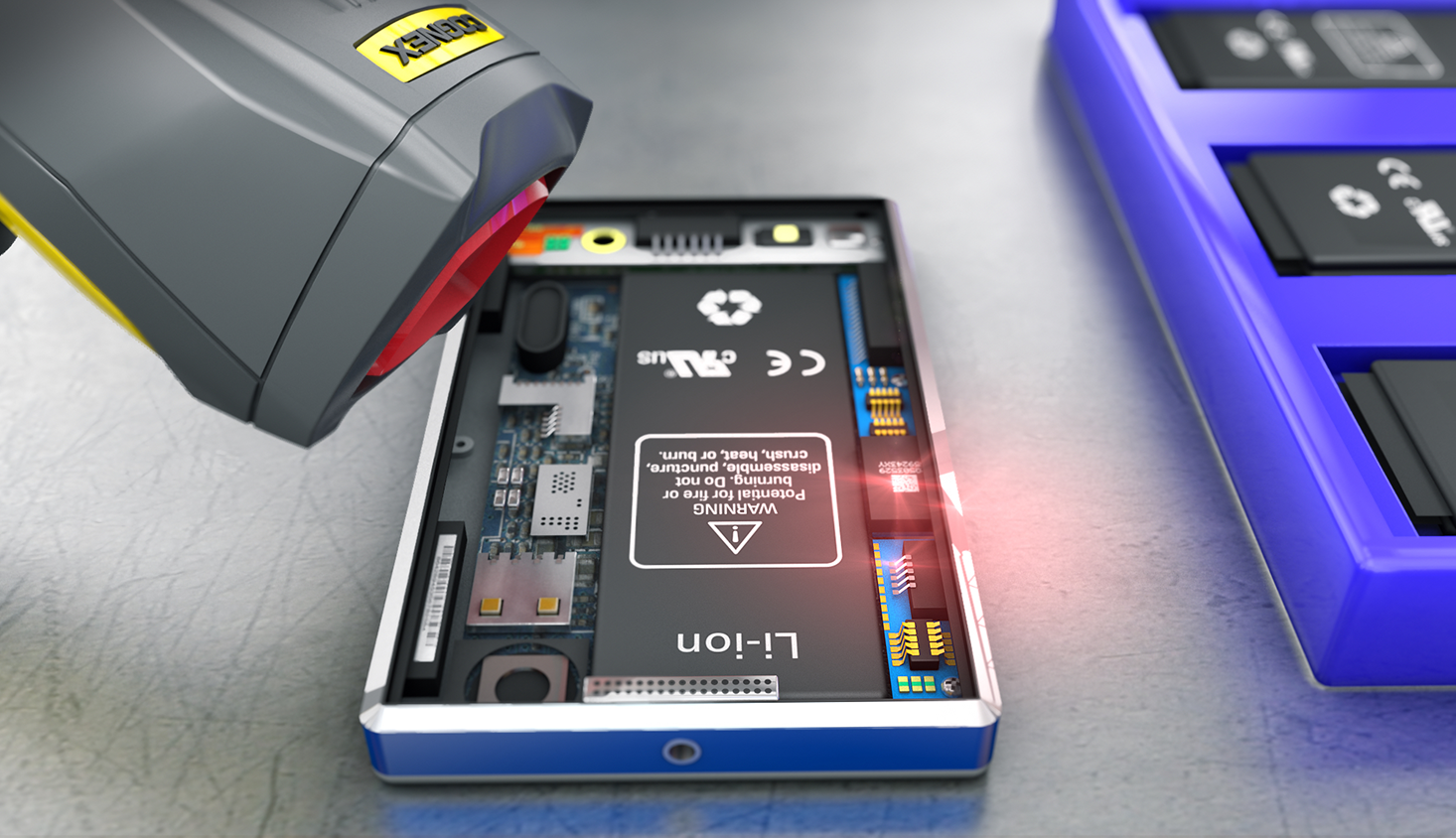

Barcode verification with Cognex verifiers

The verification of barcodes helps ensuring the readability of the barcode throughout the complete

supply chain.

Barcode verification is the process of grading the quality of barcodes. A barcode verifier assigns

an overall grade to a code based on measurements of several quality parameters. Depending on the

code type they apply different national and international standards.

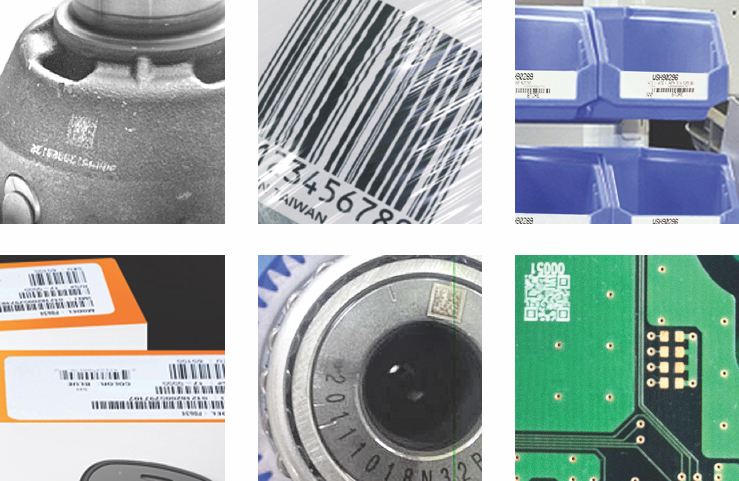

Code substrates affect reflectance differently and influence lighting angles