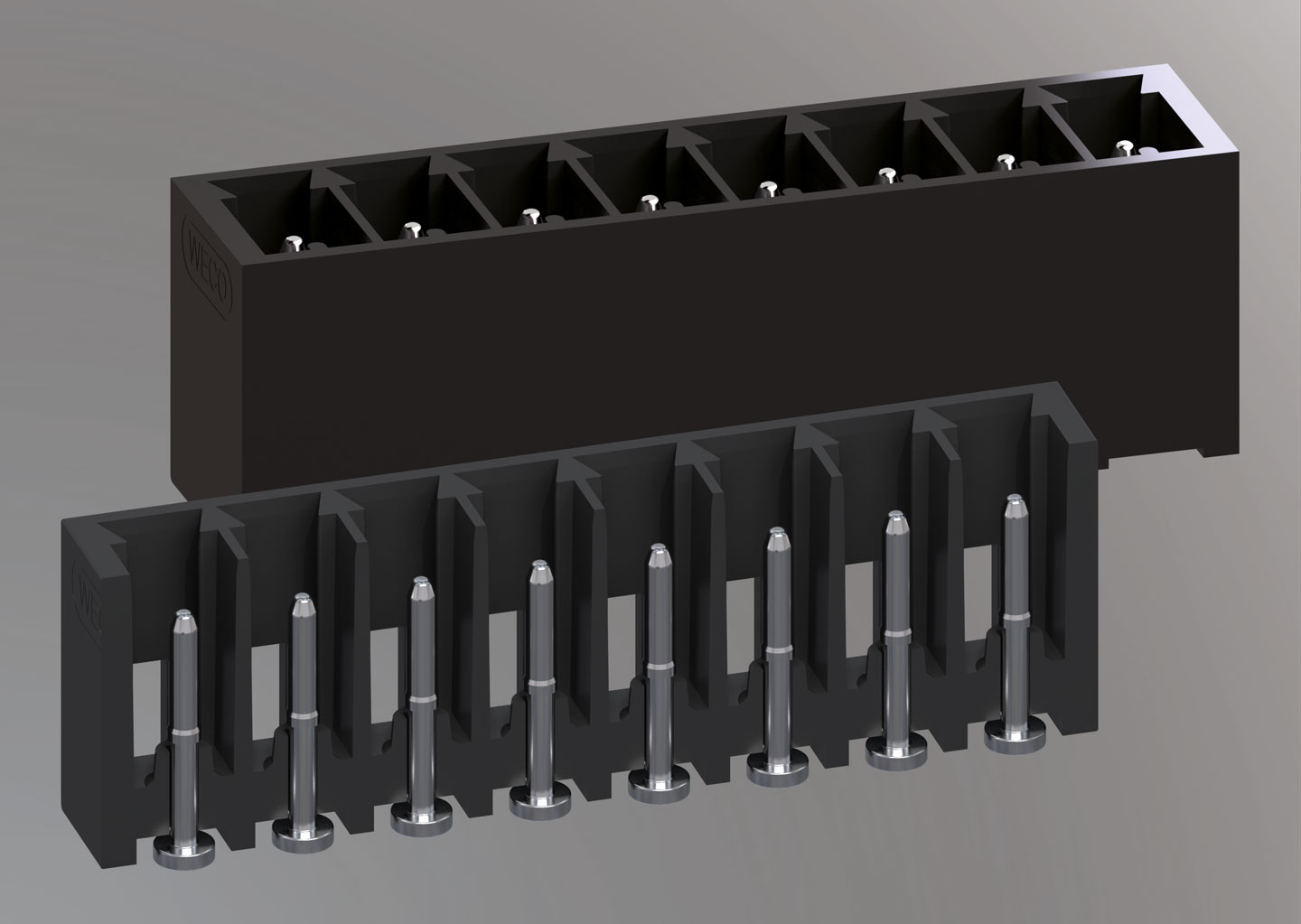

Floating terminals

Connector technology

The general trend towards ever smaller components is also evident in electronics manufacturing. The

"Internet of Things" (IoT) and the triumph of Industry 4.0 are increasing the need for space-saving

solutions. In addition to high performance, flexibility is therefore also required for PCB assembly.

Surface Mount Technology (SMT) is therefore becoming increasingly popular in the field of PCB assembly, also for solutions for industrial applications.

Surface Mount Technology (SMT) is therefore becoming increasingly popular in the field of PCB assembly, also for solutions for industrial applications.

Surface Mount Technology began its success story in the field of consumer electronics. In the meantime, this

technology has also arrived in other areas, such as industrial electronics, office and data technology,

communications technology, automotive electronics and control and measurement technology. The reasons for this

are economic efficiency, but also the technical advantages of SMT.

Today, printed circuit boards should be equipped with all the necessary active and passive components on both

sides. This is particularly crucial for applications where only limited installation space is available. Here,

"Surface Mount Technology" offers itself as an alternative solution.

SMT uses small components that are no longer equipped with pins but are mounted directly on the PCB. This eliminates the need for holes for mounting the necessary components.

SMT uses small components that are no longer equipped with pins but are mounted directly on the PCB. This eliminates the need for holes for mounting the necessary components.