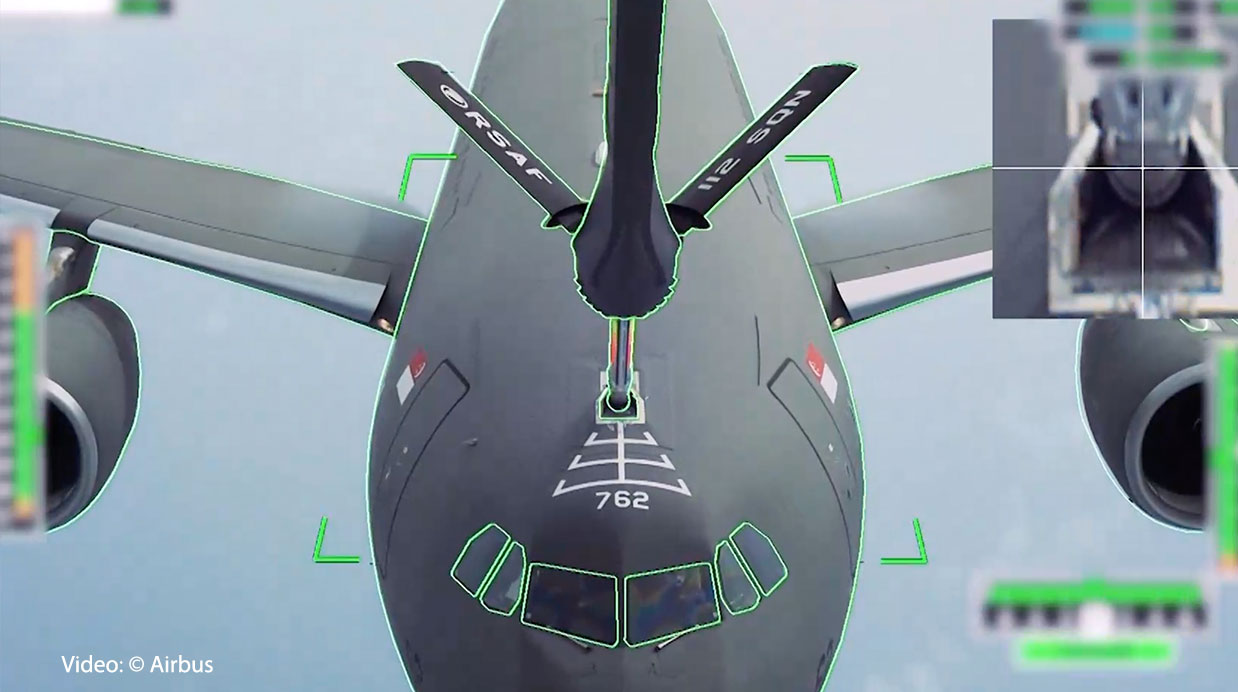

Wind River Supports Airbus in its Certification Milestone

Real-time software solution

“A3R is a significant milestone in the evolution of airborne refueling systems. It is an honor to

work with Airbus and play an important role in its latest A3R achievement,” said Avijit Sinha, chief

product officer, Wind River.

“The use of our industry-leading technology demonstrates continuing

Wind River leadership in safety-critical real-time software solutions for mission critical systems.

Wind River is able to help customers successfully navigate the challenges and complexities around

certification.”

“Airbus is the first worldwide company to certify an airborne military equipment with an embedded

multicore processor to the highest assurance level DAL-A covering CAST-32A requirements.