Special Industrial PC / HMI

Such displays must withstand very harsh environments. As a result, the display brightness must be significantly

improved, or the effect of high ambient brightness must be reduced. Otherwise, the displayed images would appear

washed out and especially the color saturation would be completely lost. For classic displays in transmissive

mode (e. g., TFT) or for self-illuminating ones (e. g., AMOLED), surface brightness’s of at least 2,000 nits

(cd/m2) are required for good readability.

However, displays with such high brightness have significant

disadvantages such as high-power consumption, burn-in effects, limited lifetime, and large power dissipation

leading to high temperatures.

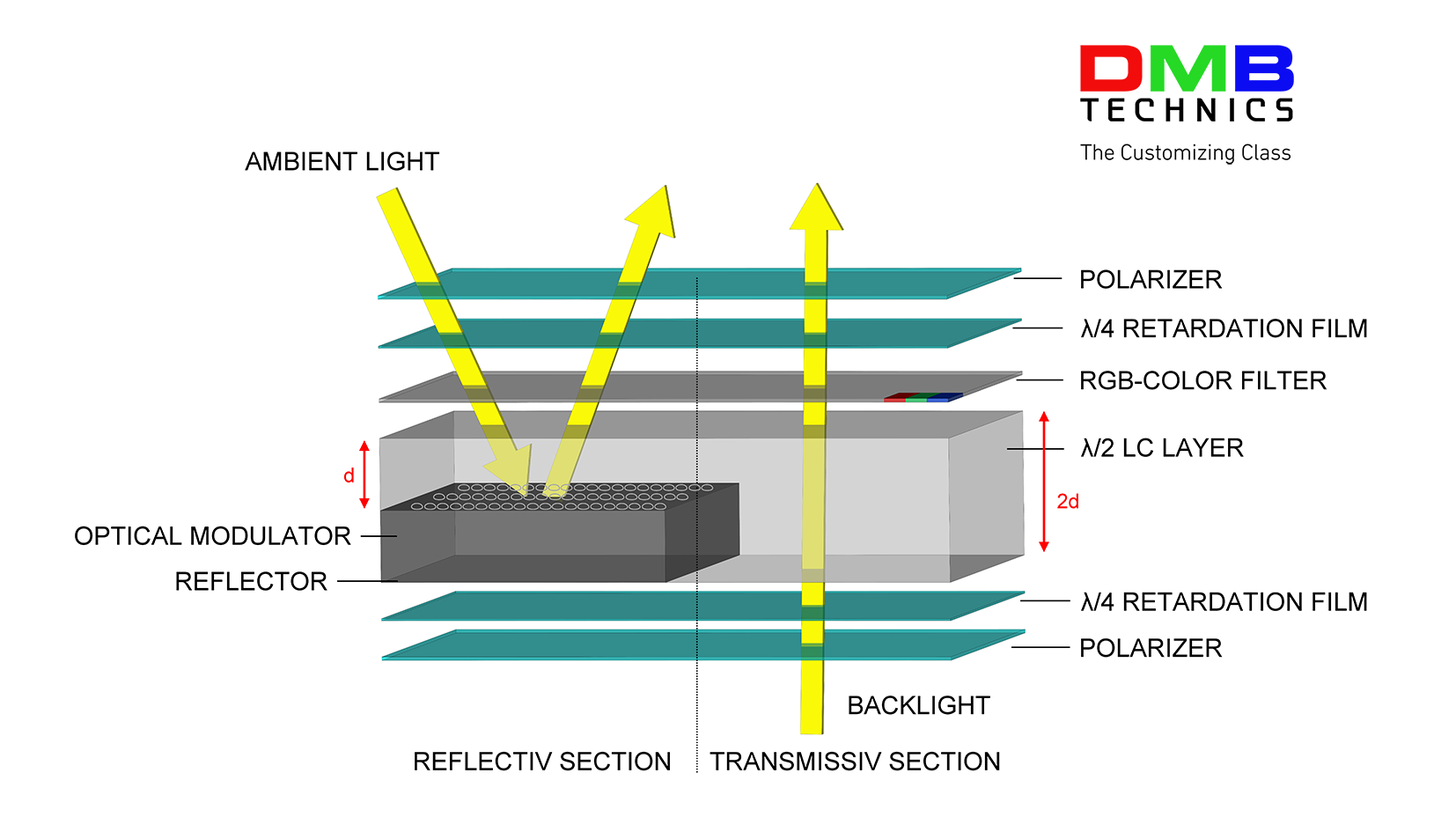

Transflective display systems have been available on the market for some time. Older technologies achieve a

reflectance of about 1 to 2 percent of ambient light. However, these displays are no longer up to date in modern

applications.

High reflectance

for good display

The latest display technologies achieve a reflectance of up to 16 percent. This ensures high colour saturation

and contrast even under direct sunlight (Image 1).

With ECB (Electrically Controlled Birefringence) technology in combination with TN (Twisted Nematic) or IPS (In

Plane Switching) technology, excellent contrast and colour values can be achieved under a wide range of

conditions.

E-bike displays – getting out of comparability