Innovative technology

The MobileRob, MR-1, enables smooth intralogistics

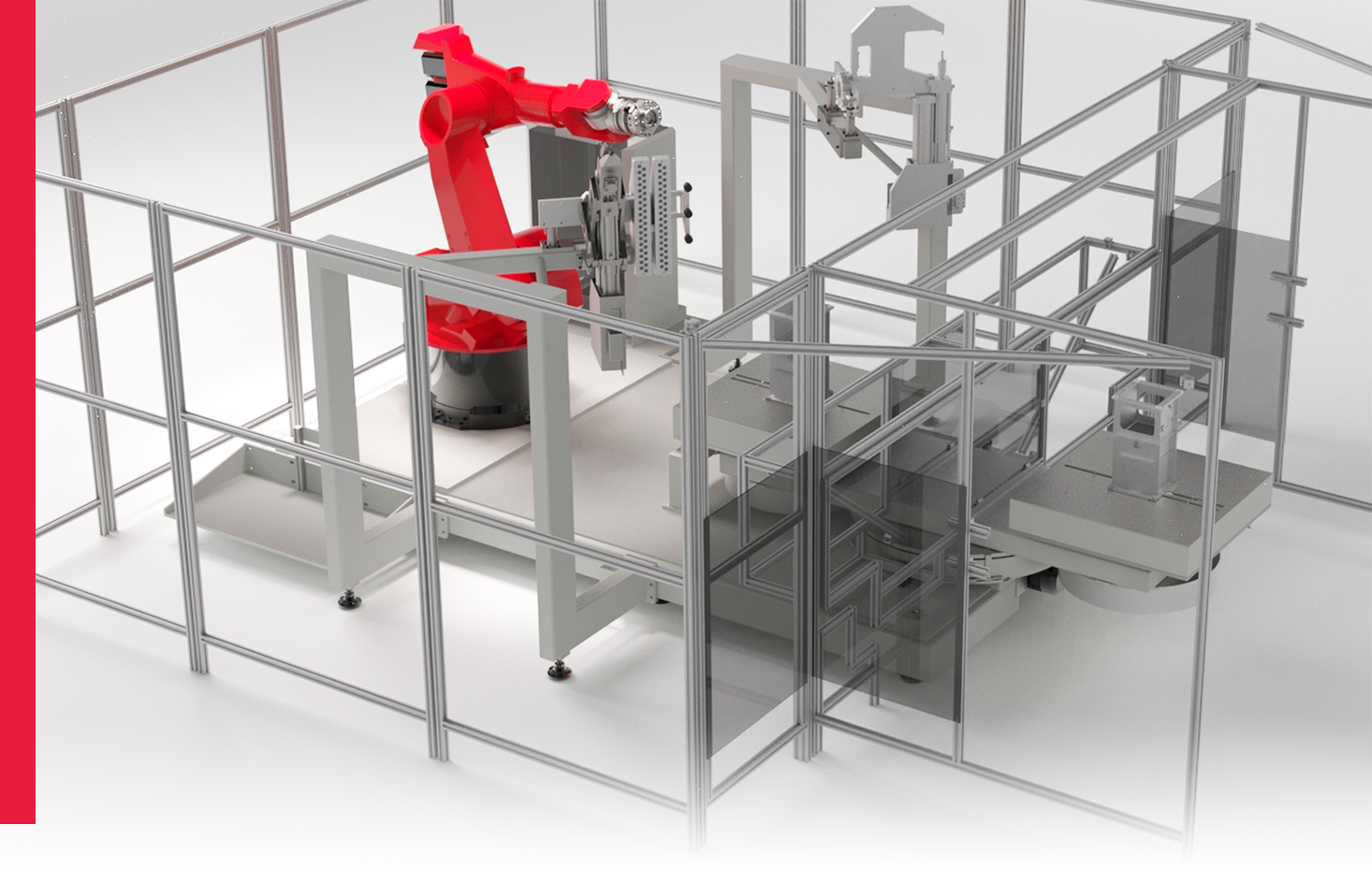

The automation module TopRob6, which is designed for one to two processes, is also suitable for

the automation of individual machines. Together with a storage tower, it forms the central building block of

efficient loading units. In line with SW Automation's modular concept, the TopRob6 can be linked to SW's other

automation modules via standard interfaces.

The MobileRob, an Automated Guided Vehicle (AGV), can be used for the internal transport of workpieces. For example, it supplies machine tools and systems with raw parts and removes processed parts without a driver. It creates a position map without programming and orientates itself independently. The system can serve as an essential component of matrix production by linking production lines to form adaptive process chains in which individual components run through the order-specific processes required.

7-axis robot gantry

7-axis robot gantry

Automated Guided Vehicle AGV

Automated Guided Vehicle AGV

The MobileRob, an Automated Guided Vehicle (AGV), can be used for the internal transport of workpieces. For example, it supplies machine tools and systems with raw parts and removes processed parts without a driver. It creates a position map without programming and orientates itself independently. The system can serve as an essential component of matrix production by linking production lines to form adaptive process chains in which individual components run through the order-specific processes required.