"Since the variable and flexible interlinking takes place via standard interfaces, downstream processes or

third-party machines can also be integrated into the overall system, and subsequent adjustments in the field,

including system downsizing, are easily possible," explains Makis. In order to achieve increased availability,

the automatic connection of the processes is not firmly coupled, but automatic buffers are installed so that failures can be better cushioned. The basic modules, for example for machine assembly or

subassembly, are designed by SW Automation so that they can be used for as many product variants as possible.

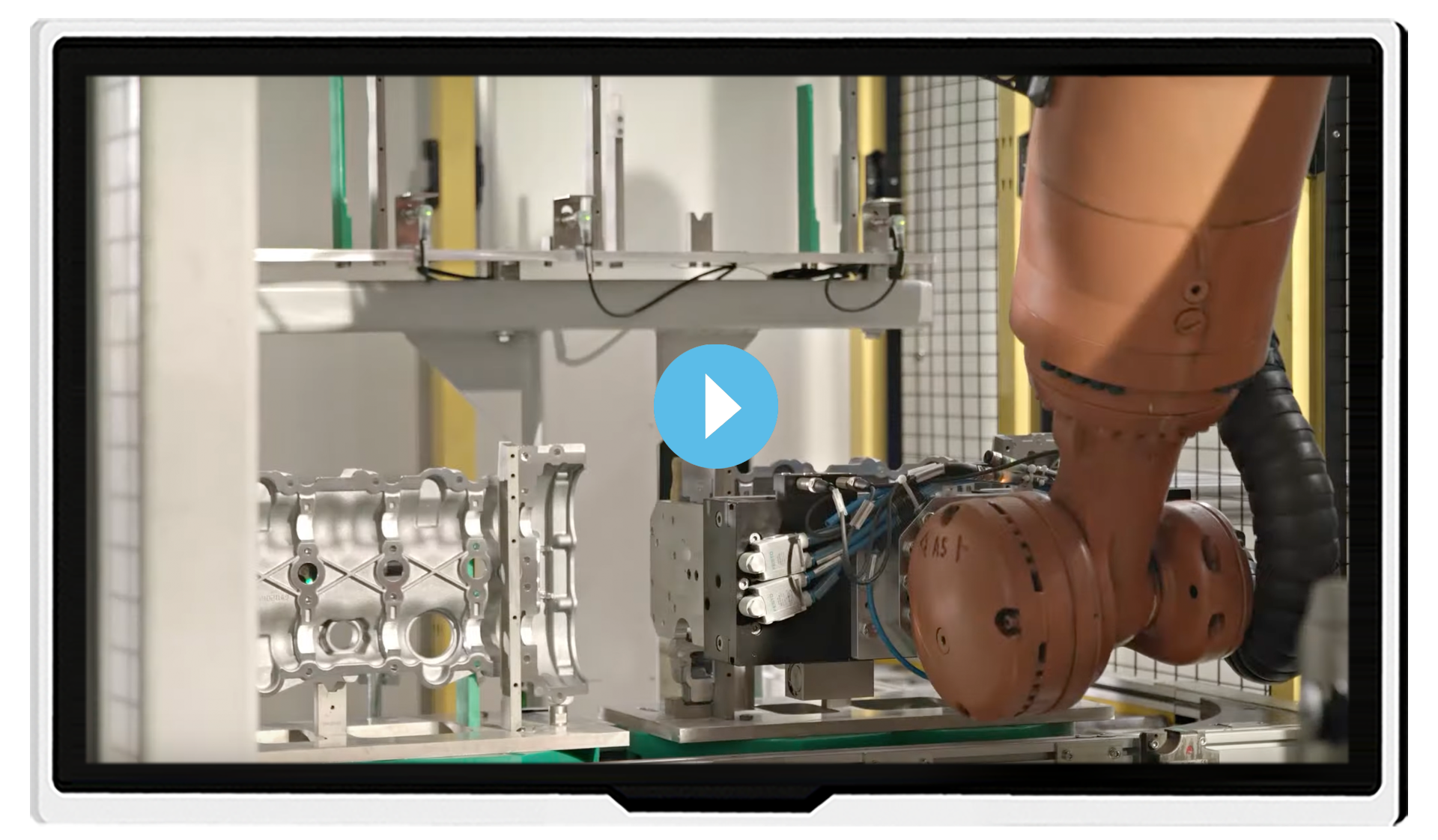

They can be supplemented as needed with individual, more customised components. A modular robot, for example,

does not only have a single hand to lift cardan shafts or housings with different outer contours from the

conveyor and place them in the machine. Instead, it is equipped with several standard hand and finger modules

suitable for the respective workpiece, which can be changed as required.

To enable even more flexibility for the entire production plant, the individual machine controls are also connected to the SW platform. SW products and the machines provided by the customer for downstream processes are brought together in this higher-level control system. The software allows central access to the plant status, control of production orders, item-related data storage and retrieval for traceability purposes, remote maintenance functions, KPIs and web visualisations.Turnkey solutions for

SW Automation offers complete turnkey solutions in association with SW, which include all components up to

the control of the complete system. In addition, the company also designs automation solutions outside of

machining and independently of the parent company's machine tools. For example, the company develops systems for

assembly automation, such as for the processes of screwing, joining and gluing. These systems also benefit from

a connection to the SW platform.

Thanks to the modular principle and the other services provided by SW Automation, the entire automation concept no longer needs to be changed for individual product changes. In view of the increasing number of variants and shorter product runtimes, this ensures long-term investment security for automotive suppliers.

E-mobility

E-mobility

To enable even more flexibility for the entire production plant, the individual machine controls are also connected to the SW platform. SW products and the machines provided by the customer for downstream processes are brought together in this higher-level control system. The software allows central access to the plant status, control of production orders, item-related data storage and retrieval for traceability purposes, remote maintenance functions, KPIs and web visualisations.

Turnkey solutions for

automated production

SW Automation offers complete turnkey solutions in association with SW, which include all components up to

the control of the complete system. In addition, the company also designs automation solutions outside of

machining and independently of the parent company's machine tools. For example, the company develops systems for

assembly automation, such as for the processes of screwing, joining and gluing. These systems also benefit from

a connection to the SW platform.Thanks to the modular principle and the other services provided by SW Automation, the entire automation concept no longer needs to be changed for individual product changes. In view of the increasing number of variants and shorter product runtimes, this ensures long-term investment security for automotive suppliers.