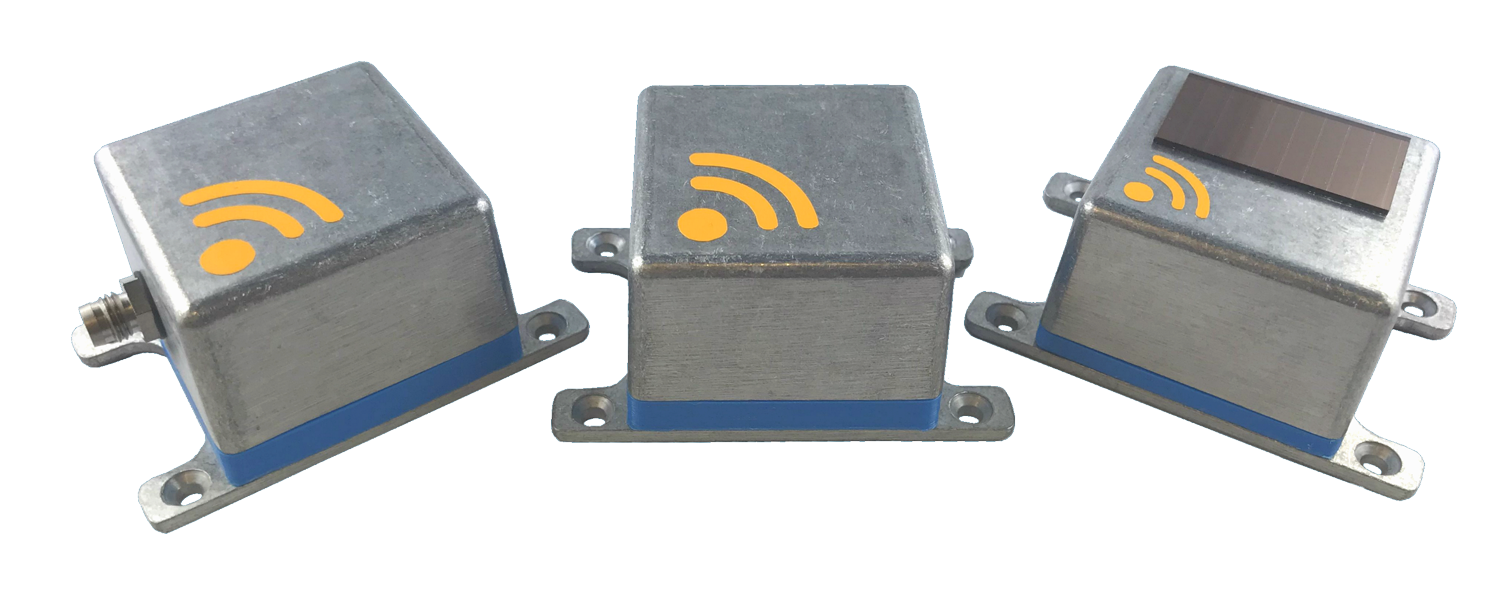

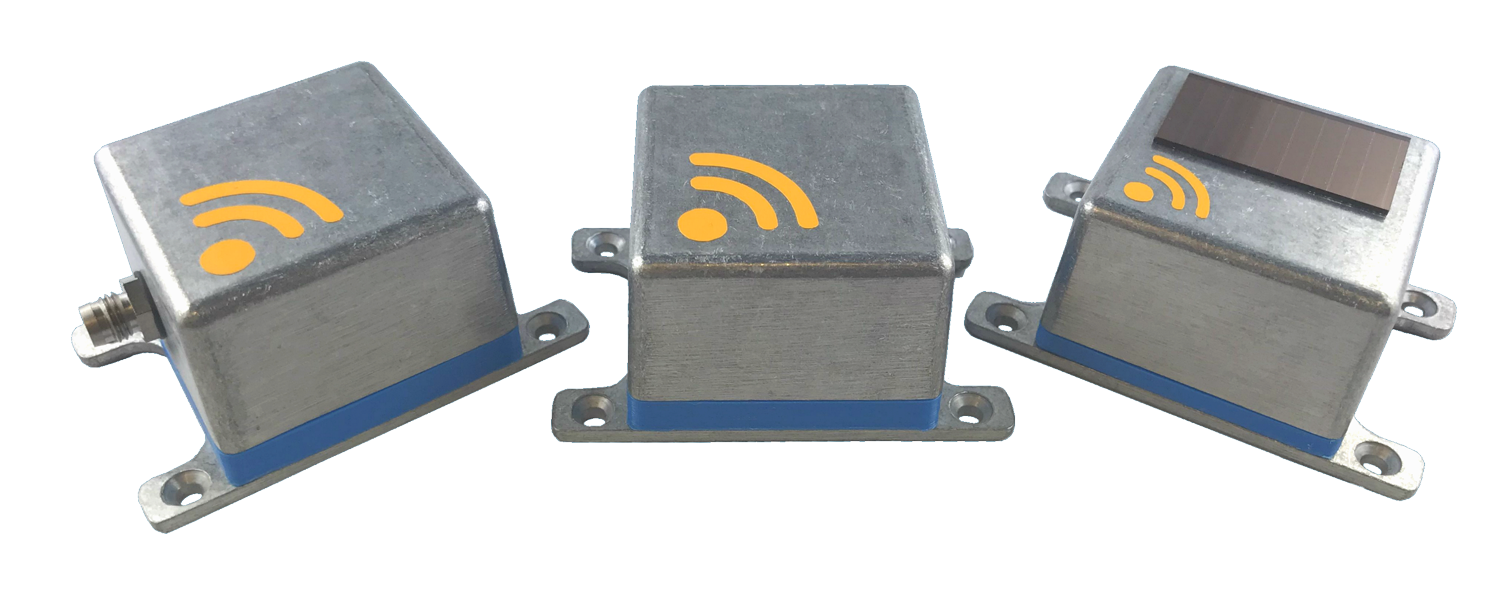

These are easy to retrofit, obtain their energy from light and ambient temperature (energy harvesting) and

combine this with unique low power communication technology. They represent a cost-effective, robust, and easily

retrofittable solution for condition monitoring, especially in the paper and steel industries. Fault messages

detected by the sensors, e. g. increased bearing vibrations of a paper roll, are transferred to the cloud-based

5i.Maintenance application via the endiio gateway.

5i.Maintenance is a module of the 5i.Manufacturing Excellence Cloud, the intuitive digital working environment

for the factory. In the app, all maintenance processes are recorded and transparently managed. The result: a

one-stop solution that seamlessly integrates messages from condition monitoring into daily maintenance

workflows, allowing even complex plant technology to be monitored from any location.

Intelligent App Combined with Powerful Condition Monitoring

The background to the collaboration was that the typical workflow for maintenance and repair in the process

industry is often still analogue:

Tasks are reported manually, work reports are recorded on forms and then later

entered manually into IT systems. “The solution developed together with endiio enables an increase in efficiency

for maintenance: maintenance requirements from condition monitoring are automatically integrated into the daily

work of maintenance. This saves valuable time and enables data to be collected for the continuous improvement

process, as historical sensor data is available linked to the remedial measures taken,” says Dr. Jan-Marc

Lischka, Co-Founder of 5thIndustry GmbH.

Complex plants independently report process interruptions

Any abnormalities in plant operation, such as increases in bearing vibrations, unusual temperature developments

or even the attainment of a defined operating time, are recorded via the retrofittable endiio modules. After a

learning phase of several days, an automatic status analysis of the monitored components is carried out every 15

minutes. As soon as an anomaly is detected in the trend analysis, a message is sent to the cloud via the endiio

gateway. The gateway is linked to the maintenance application 5i.Maintenance, so that the plants can report

maintenance requirements themselves, as it were, without the need for manual input. Specific error descriptions

are stored so that maintenance specialists can immediately recognize what needs to be done. “This is achieved

through the clever use of the interfaces offered by our modern cloud solution,” says Lischka.

All information at a glance – through an app

For employees in production and maintenance, this means: With a single app, they can access all

maintenance-relevant processes. All fault messages – whether from condition monitoring or recorded by employees

– can be seen at a glance and can be processed efficiently.

The wireless sensor modules obtain their energy from light and ambient temperature (Image: ENDIIO)

.jpg)