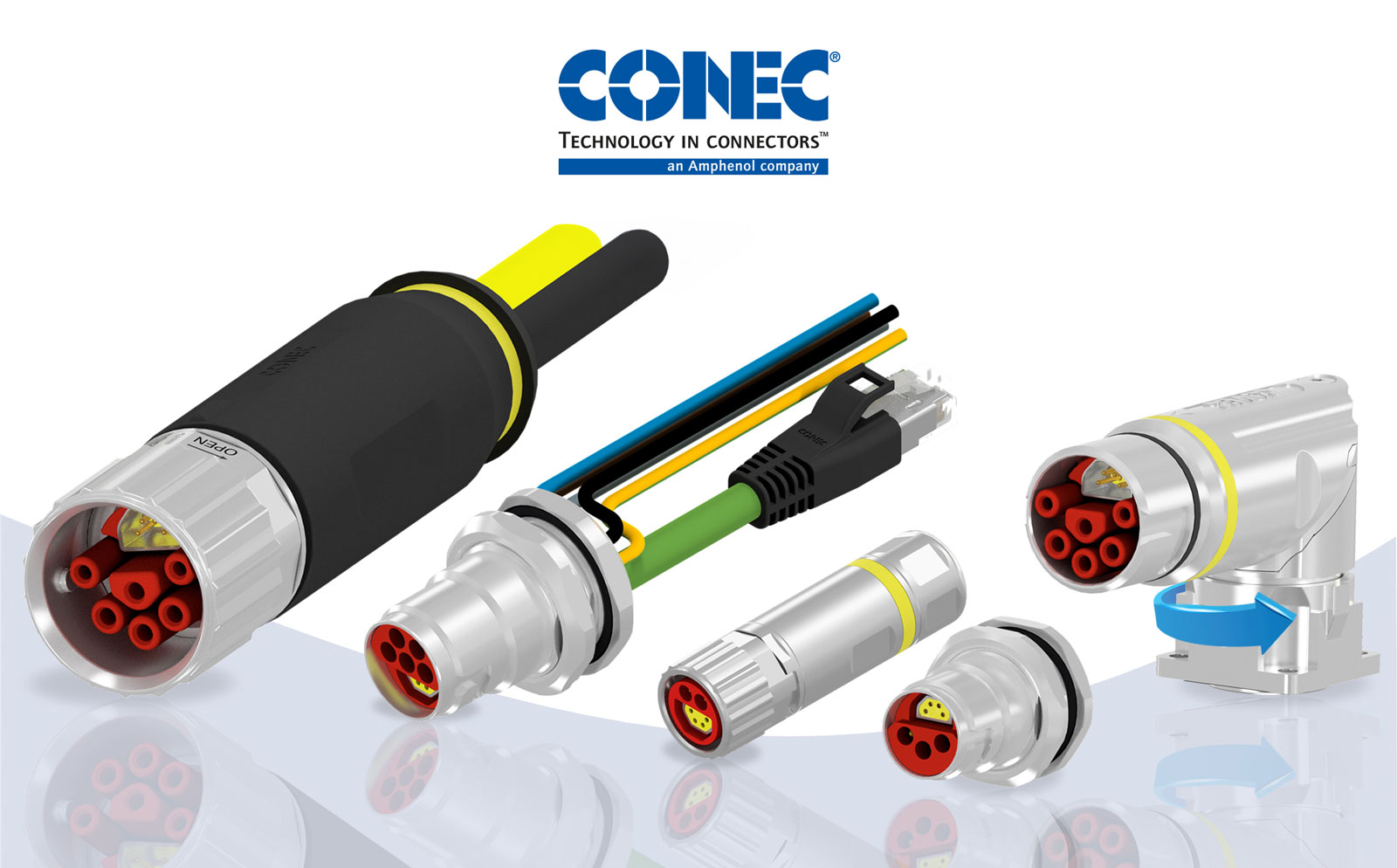

One-cable Hybrid Connectors

Greater flexibility and efficiency in plant and mechanical engineering

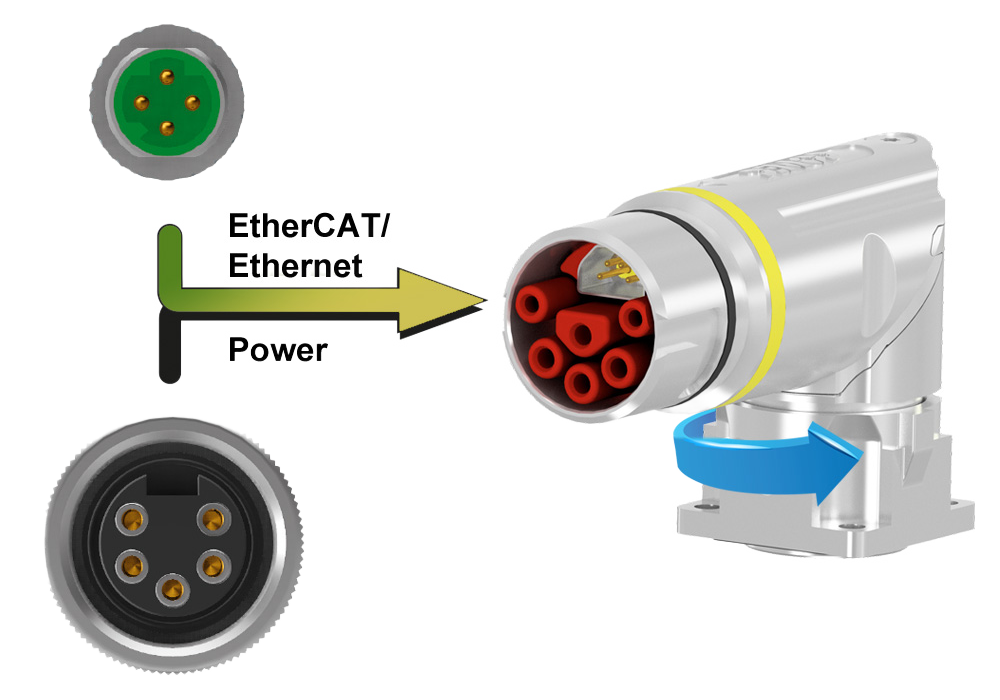

Conec offers Hybrid Connectors for almost every performance class in the four sizes B12, B17, B23 and B40. CONEC Hybrid Connectors will soon be standardised in accordance with IEC 61076-2-118.

Why are Hybrid Connectors used?

Conventional cabling of electric motors, servo drives or linear units is often very complex. Separate cables are used for power, data, and signal transmission for different tasks. This wiring concept is not only expensive, but also difficult to maintain. It also takes up a lot of space. Increasing cost pressure and the miniaturisation of end devices make new solutions for more efficient cabling just as necessary as constantly increasing data volumes and high transmission speeds.