Identification solutions ensure that the right interchangeable parts are used when changing formats. This is

an

efficient way to avoid errors and damage to machines caused by incorrect parts as well as implement

intelligent

machine designs.

Format change made easy

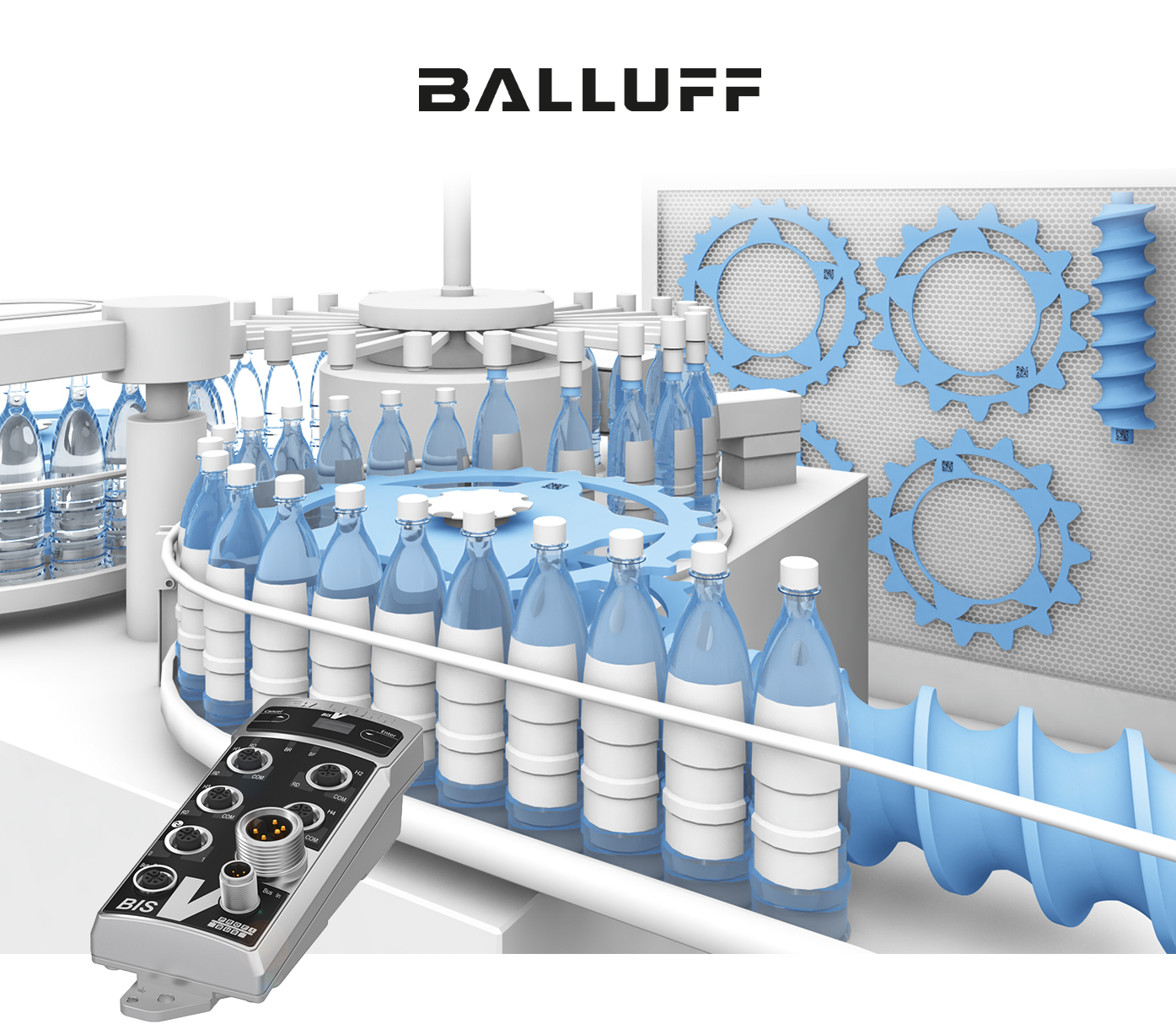

RFID data carriers, which can be read out or written to without contact, are used in place of barcodes,

metal

tags or laser-etched/dot-peened codes for labeling the interchangeable parts. This method works even when

the

tags are slightly dirty. The BIS M system offered by Balluff is the perfect HF RFID solution for this (13.56

MHz). Based on the application, different system combinations of processor unit, read/write head and data

carriers can be used. The website of the provider offers an RFID configurator on its website, which is

intuitive

to operate and provides practical support in selecting the right components.

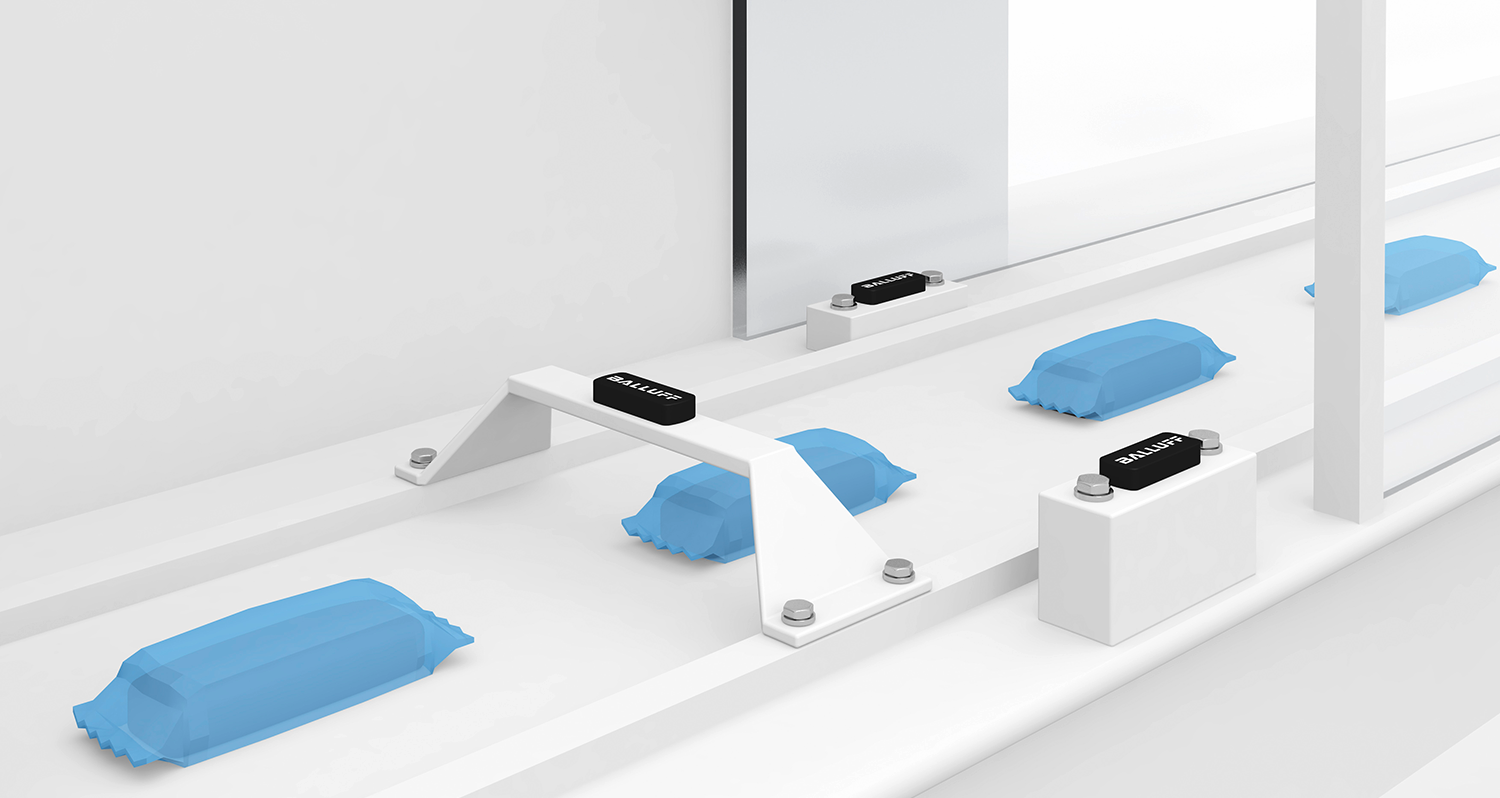

When the machine controller is used optimally, it automatically evaluates all information, initiates the

corresponding stored actions and thereby actively supports the user. The system only starts up when all the

interchangeable parts are placed and fixed at the proper location.

RFID allows data such as the operating life of the specific interchangeable part to be read in using the tag

so

that this information can be updated each time the part is used. If a part needs to be replaced or reworked,

a

notification or alarm is issued in the machine controller before fault conditions can arise. And those who

want

to differentiate original parts from those of third-party suppliers can also use RFID for this purpose. This

provides guarantee protection, increases machine safety and protects the intellectual property of the

machine

manufacturer.

▪ ds

Find out more now!

Find out more now!

sps 2019 – Hall 7A, Booth 303

Nuremberg, 2019, November 26 ‑ 28