Filling process 4.0

Maintenance during operation

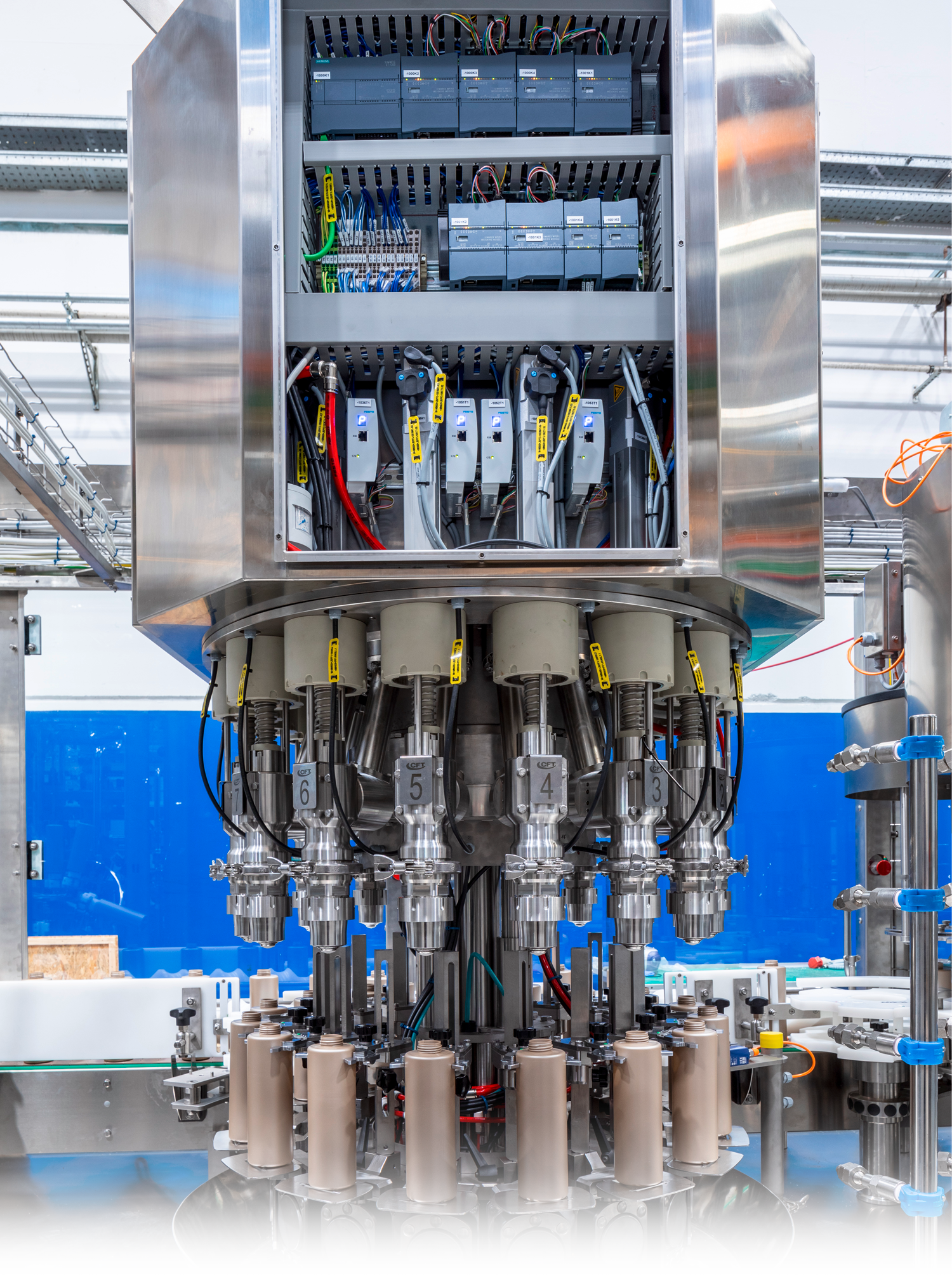

The rotary filling

line meets strict safety requirements and increases production capacity

The CFT Group (CTF) designs and builds production lines and turnkey systems

primarily for the food and beverage industry. One of its customers, Menz & Gasser, which specializes in

producing and packaging preserves and honey in portions for hotels, restaurants and catering, had CFT

develop a rotary filling plant to a very high specification. For this project, the CFT Group relied on

motion control solutions from Siemens.

The plant was to meet strict safety requirements and increase production capacities, while being exceptionally

user-friendly. Key elements were extremely easy maintenance of the machines, ideally during operation. To

achieve this, CFT turned to motion control solutions from the Siemens portfolio. This ensured that not only were

the customer’s strict safety requirements satisfied but the cost for planning and commissioning each individual

machine could be reduced by approximately 30 percent due to the Siemens technology.