Power

DC-DC converters are used in many applications; telecom, data communications, test and measurement, process

control, semiconductor fabrication, industrial manufacturing, medical devices and battery powered equipment.

They offer a simple way of deriving additional low power outputs from a higher power AC-DC supply, for example a

24 V output driving motors, relays or pumps. Alternatively if the system is powered by a 12 V battery, DC-DC

converters can provide stable, regulated voltages during the battery’s charge and discharge cycles. Controllers,

logic circuits and integrated circuits often require single, or dual, 3.3 V, 5 V, 12 V and 15 V outputs to operate

from.

The size reduction of isolated DC-DC Converters has certainly been dramatic in the past few decades. In the

1970s a 1.5 W board mount converter measured 45 x 30.5 x 16.5mm (22,646 mm3). In

2020 the benchmark for a 3 W is

1,642 mm3. On average DC-DC converter power density has doubled every 10 years.

New technologies for DC-DC converter design

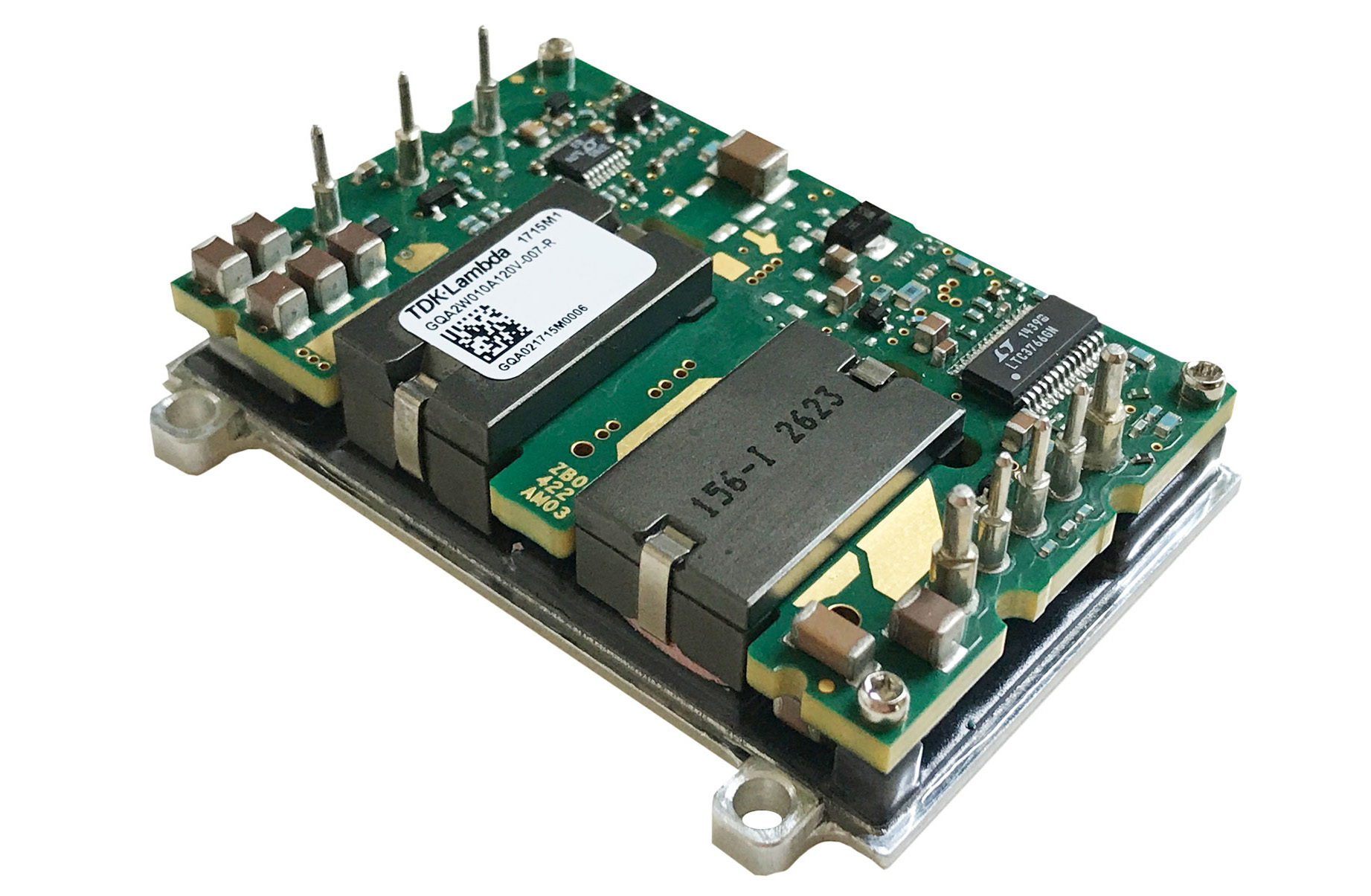

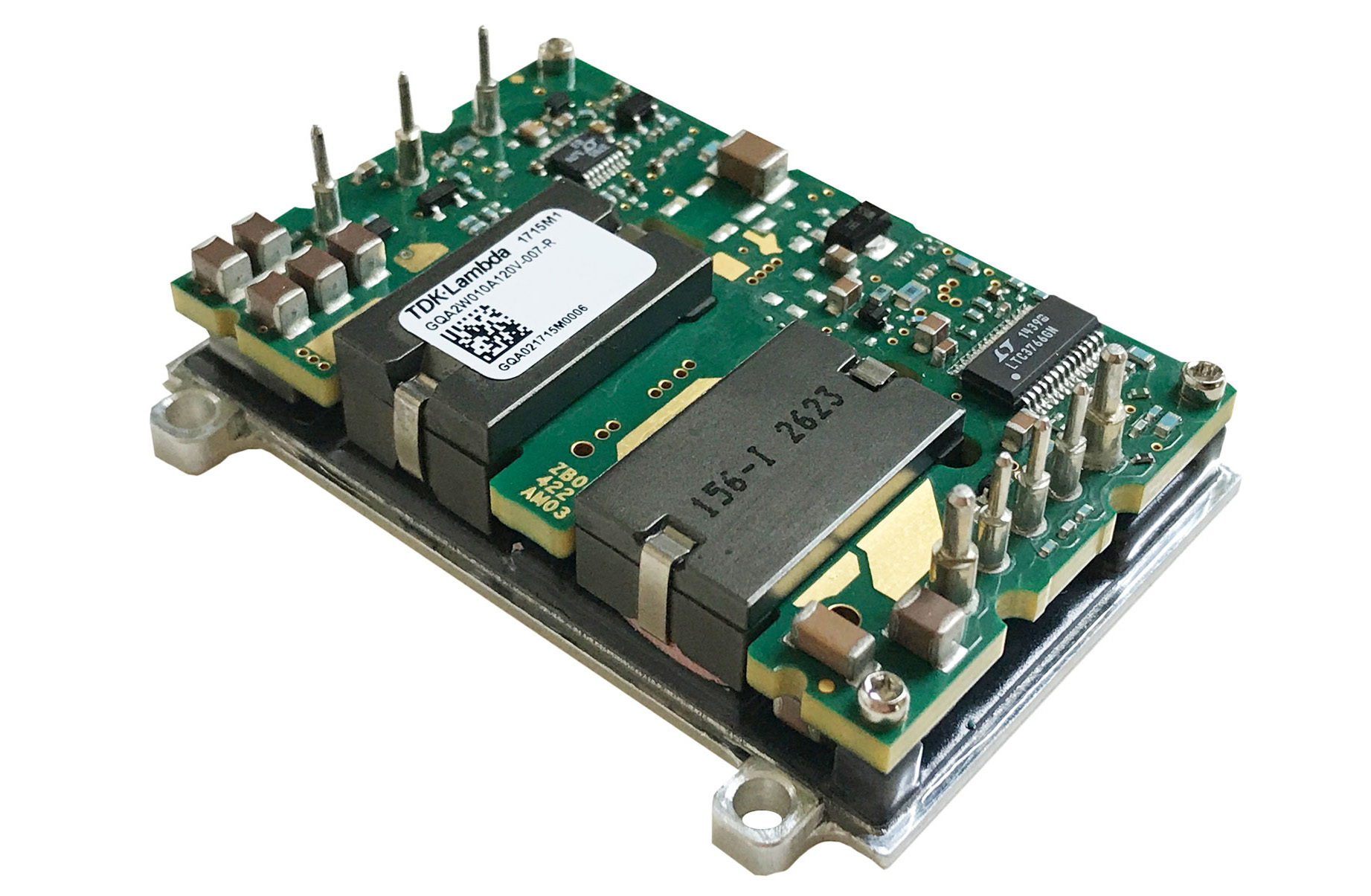

This has been primarily due to major improvements in efficiency as new topologies and techniques have been developed. These include bridgeless rectification, the use of highly efficient GaN (Gallium nitride) devices, synchronous rectification and digital control. Low loss ferrite materials have enabled transformers and inductors to dramatically shrink in size. The power transformers on many high power DC-DC models now utilise integrated copper tracks on a multiple layer printed circuit board as windings. This eliminates traditional wire wound bobbin constructions and the ferrite cores are simply mounted on each side of the board.

GQA power module with transformer winding integrated in the printed

circuit board