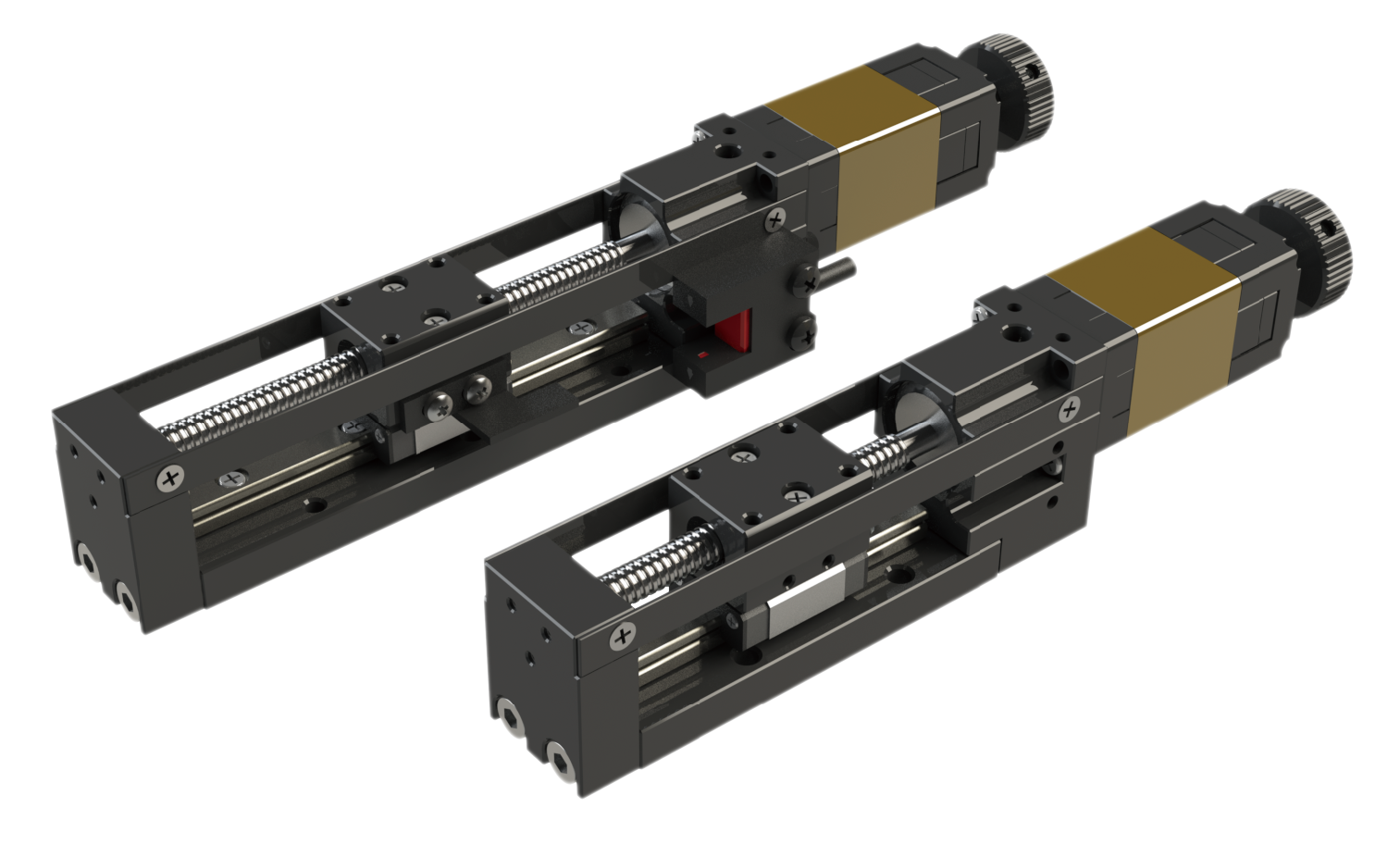

KSS has released the CAS series (distributed by Dynetics) with high-performance mini actuators for precise

strokes on a small scale and for use in single and multi-axis assemblies. The linear actuators have a long

service life. The compact and powerful lightweights are 15 by 23.5 millimetres small and available in lengths of

107 and 127 millimetres. The linear actuators are suitable for automation applications in laboratories and

packaging and medical technology – for example, for single-axis and multi-axis assemblies.

They are driven by 2-phase hybrid stepper motors in NEMA 6 flange size.

The coupling-free construction with the

spindle ensures tight tolerances, precise attachment and saves weight, which in turn makes a small NEMA 6 motor

for the mini actuator sufficient for performance, precise guidance and power.

Accurate and energy-saving

The high-performance linear drives provide an optimal energy balance and work quickly and precisely.

Acceleration and speed can be controlled as needed. All linear drives of the new series are silent and are

characterised above all by the greatly increased mechanical stability and the improved positioning accuracy.

The built-in linear ball circulation versions provide high stiffness, greater axial force and repeatability and

absorb radial loads and load moments. Vibrations during stopover are effectively suppressed. Strokes from 20 mm

up to 40 mm and various shaft diameters are available in combination with threads and miniature ball circuit

guides or rolled ball screws, with a travel distance up to 40 mm, and an accuracy of 0.01 to 0.005 mm. Thus, a

wide selection of accuracy and thrust is available. Installation is easy.

Motion control

for multi-axis systems

For up to 4-axis positioning stages with complicated motion profiles, the PMX/Commander series offers a very

compact and freely programmable multi-axis motion controller with various interfaces.

Overview Linear actuator

Overview Linear actuator

Datasheet Actuator NEMA 6 size

Datasheet Actuator NEMA 6 size