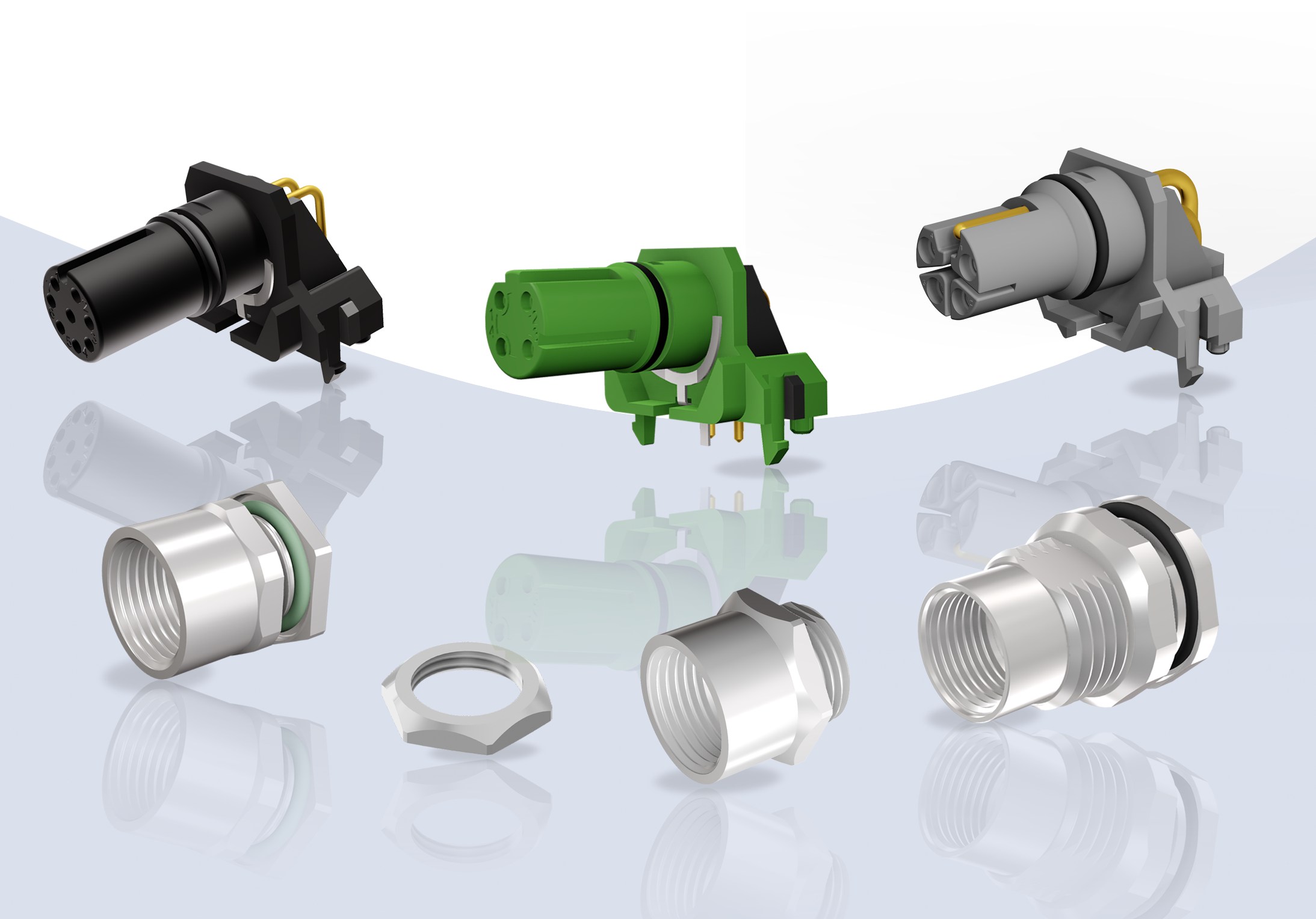

Due to the O-ring, the socket connectors are sealed against moisture from outside,

even when unplugged. The two-part circuit board sockets are available with A-coding

4-, 5-, 8- and 12-positions as well as D- coded 4-positions for front and back panel mounting.

The L-coded version is available for back panel mounting with 4- and 4+FE positions.

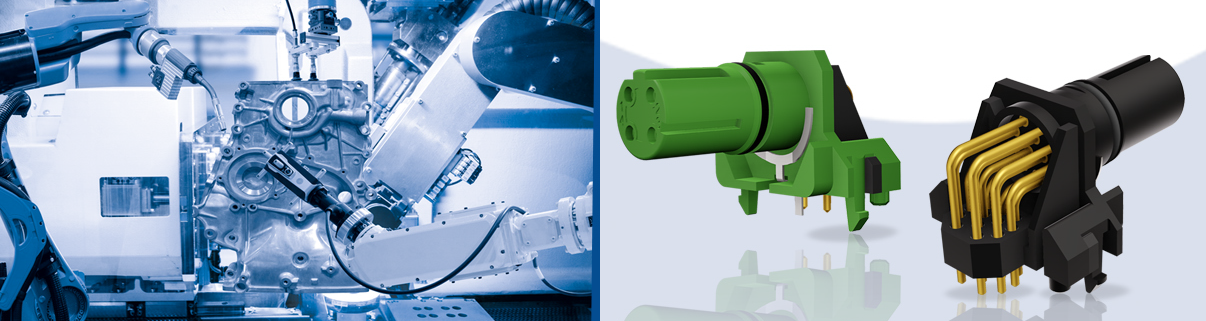

Combined mounting possible

The user can mount the board equipped with the insulating body

in various socket geometries. The CONEC sockets are suitable for

combined mounting and are ideal for a design where the M12x1 thread

of the socket is directly formed. This creates maximum design flexibility.

Secure screen connection

The insulation body fitted with angled contacts is

snapped into the circuit board and then processed in a wave solder

bath or by selective soldering.

The connector housing is screwed into the device

and the circuit board with the contact insert is mounted to it. The spring-loaded shield

plate contacts the connector housing and ensures the shield connection.

Sealed plug connection

In the installed state and locked with the counterpart, protection class IP67

is achieved. The connectors are suitable for housing wall thicknesses of 2-3 mm and for

PCB thicknesses of 1.6 mm.

The angled connector design makes it possible to position the

PCB horizontally in the device, which in turn facilitates the assembly.

The innovative M12x1 sockets meet the special requirements of the market because they are

two-parts (separation of insulating body with socket housing), modular in design, have an

O-ring on insulating body, are suitable for front and back panel mounting

(L-coding only back panel mounting), enable fast data transmission (M12x1 D-coding)

and offer a high current load capacity up to 16 A (M12x1 L-coding).

▪ ds

Benefits

- Large tolerance compensation between board and socket

- Suitable for various socket geometries

- Low load forces for the circuit board

- Low contact resistances of the shielding

- May also be used without CONEC socket housing

Fields of application

- Automation technology

- Building automation

- Communication

- Industrial interfaces

Find out more now!

Find out more now!