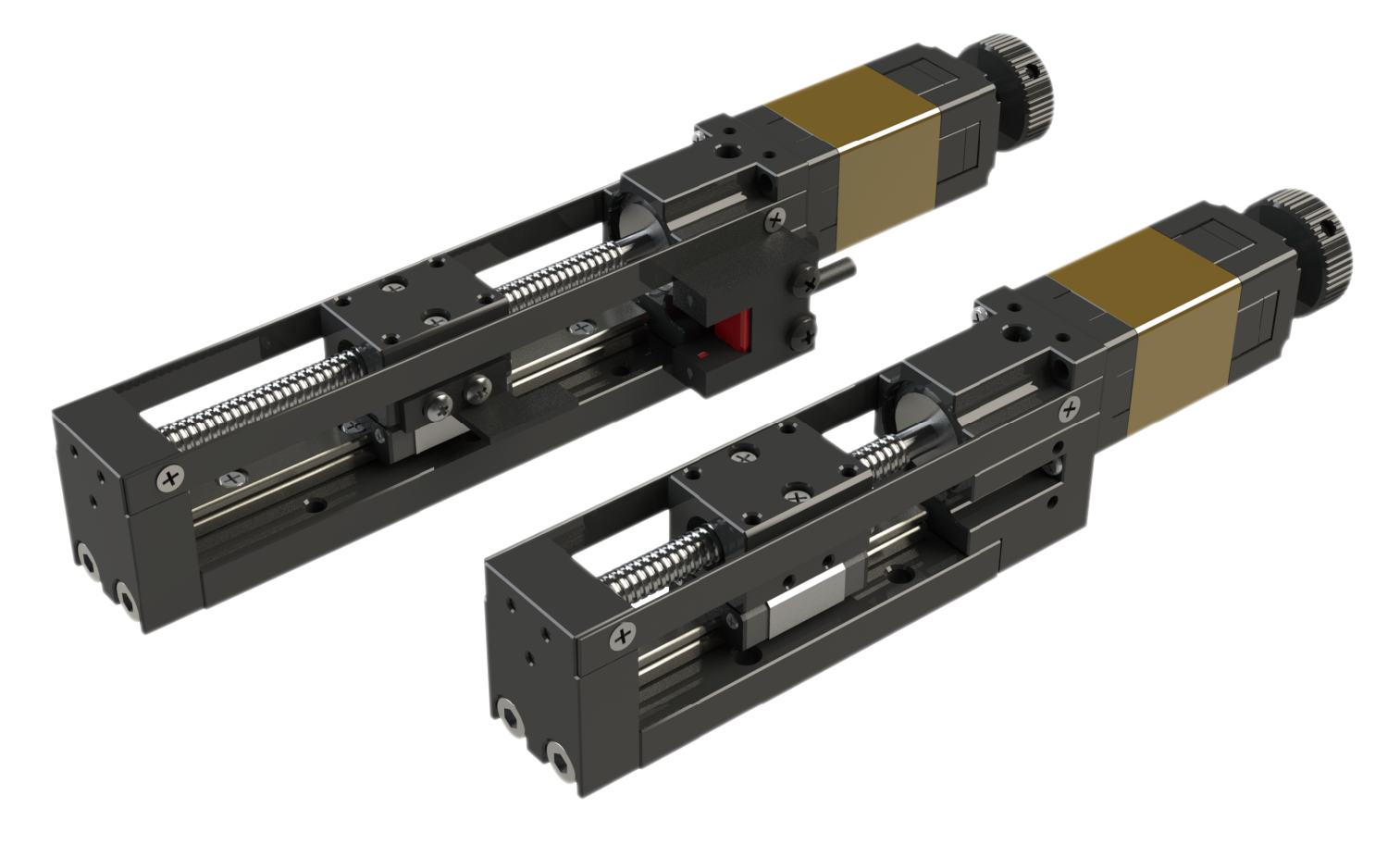

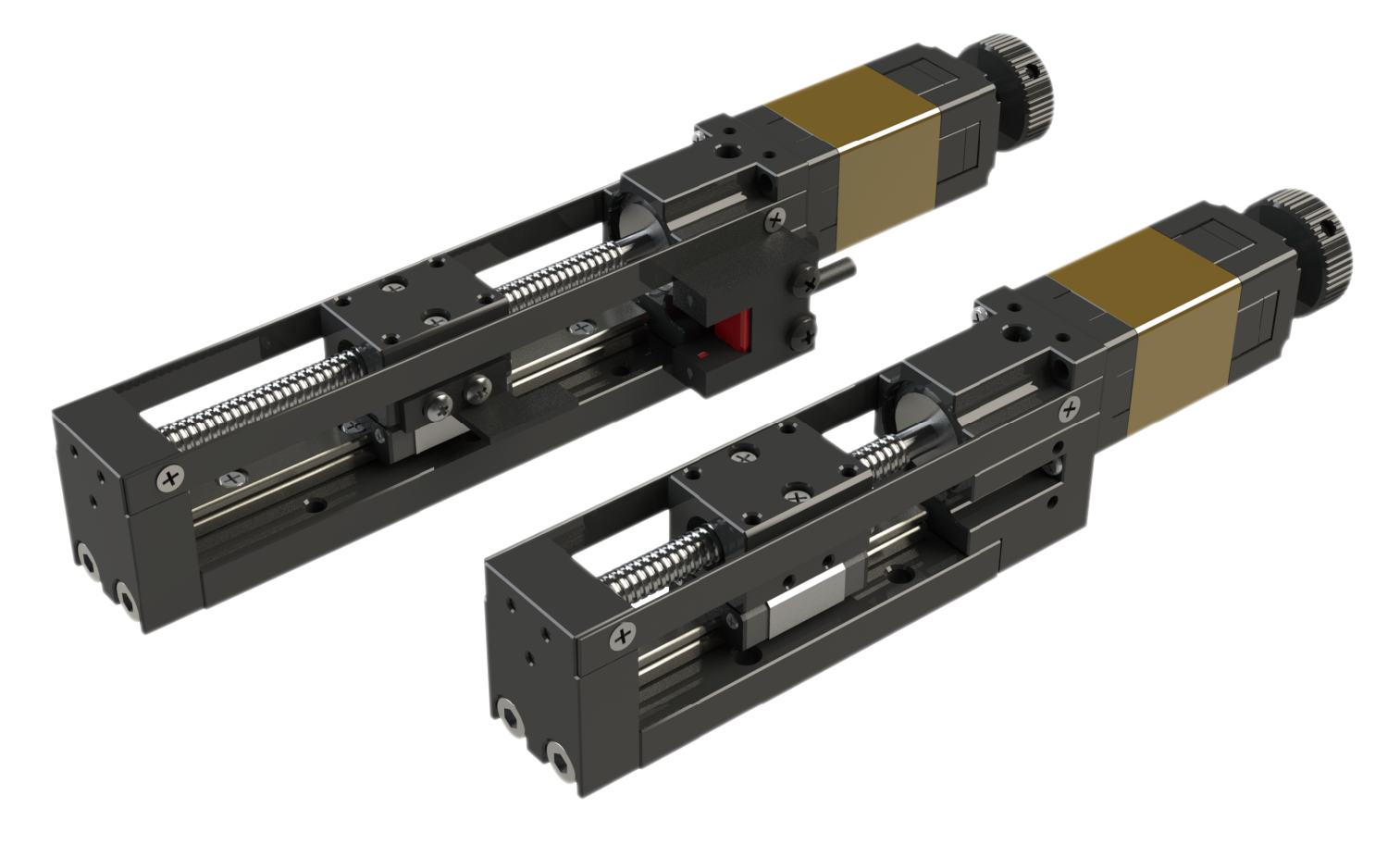

An example of compact and powerful linear actuators for short, precise strokes is the range of CAS actuators.

These have a long service life and are suitable for automation applications in laboratories as well as in packaging and medical sectors.

They are only 15 by 23.5 millimetres in size and are available in lengths of 107 and 127 millimetres.

The CAS actuator features a 2-phase hybrid stepper motor in a NEMA 6 flange size that provides a

powerful drive. The coupling-free design with the spindle ensures tight tolerances, precise

attachment, and weight savings, making a small NEMA-6 motor sufficient for the drive. This

solution ensures optimal energy balance and enables precise control of acceleration and speed.

All linear actuators in the CAS series feature nearly silent operation, increased stiffness and

improved positioning accuracy. The built-in linear ball circulation offer high rigidity, axial force

and repeatability and safely absorb radial loads and load torques. Vibrations during stoppover are

effectively suppressed. CAS actuators are offered in versions with strokes from 20 to 40 millimetres.

There is a wide range of versions that differ in terms of accuracy (0.01 to 0.005 millimetres), thrust

and travel (up to 40 millimetres). Another advantage of CAS actuators: they are easy to install.

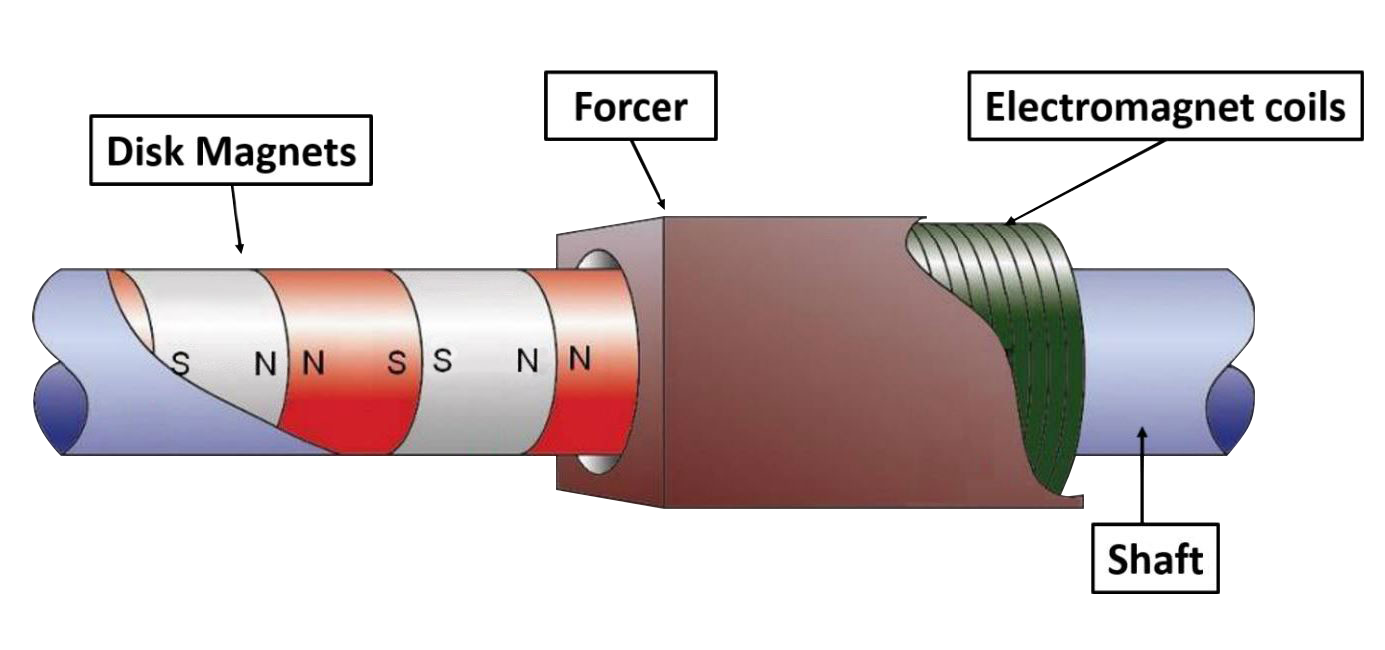

Linear shaft motors

have many advantages

Linear shaft motor adoption has grown

faster in the last decade due to the increased performance of their magnets — which in turn has made

them more power dense than early-generation versions. These motors consist of a hollow stainless steel

tube filled with a stack of ring-shaped magnets. Because the forcers/coils are wound all around the magnetic

field of the shaft, linear shaft motors from Nippon Pulse deliver around 40 percent more

power than other comparable drives.

In addition, several forcers/coils can be

installed for even more compact and flexible solutions.

This design and the fact that stronger magnets are now available enable

linear shaft motors that can deliver more than 6,000 N.

The linear servo motor requires no lubrication and shows no loss of performance due to wear and ageing.

Its maintenance-free long life contributes to a reduction in life-cycle costs.

Another advantage of linear shaft motors is that they operate without cogging and

thus have high accuracy – even up to the accuracy of the selected encoder. Resolutions

better than 10 microns are possible without an increased motor price.