ACTILINK – fully integrated servo motor

for highly dynamic applications

Servo motors are ideal for realising a dynamic motion profile and are based on a closed-loop, digitally

controlled system that receives speed and position information from a feedback device. DC motors are favoured in

robotics and are available in brushed or brushless configurations.

A stepper motor is a type of brushless motor that divides a full rotation into a series of equal steps or increments.

It relies on pulsed signals and stops immediately when it receives the appropriate command.

In the absence of power, it remains in its position. However, BLDC servo motors are significantly quieter and offer higher efficiency and accuracy over a wide speed range (3000 to 6000 rpm) than conventional stepper motors. BLDC and servo motors require a separate electronic system to control their operation. Integrated motors are units that contain all the electronics required to drive the motor.

A stepper motor is a type of brushless motor that divides a full rotation into a series of equal steps or increments.

It relies on pulsed signals and stops immediately when it receives the appropriate command.

In the absence of power, it remains in its position. However, BLDC servo motors are significantly quieter and offer higher efficiency and accuracy over a wide speed range (3000 to 6000 rpm) than conventional stepper motors. BLDC and servo motors require a separate electronic system to control their operation. Integrated motors are units that contain all the electronics required to drive the motor.

Advantages of integrated motors

The customer receives a fully wired and tested motor set (motor, encoder, safety device, driver) that shortens their test workflow and allows for faster integration compared to traditional systems.ACTILINK, the all-in-one servo drive for precise control

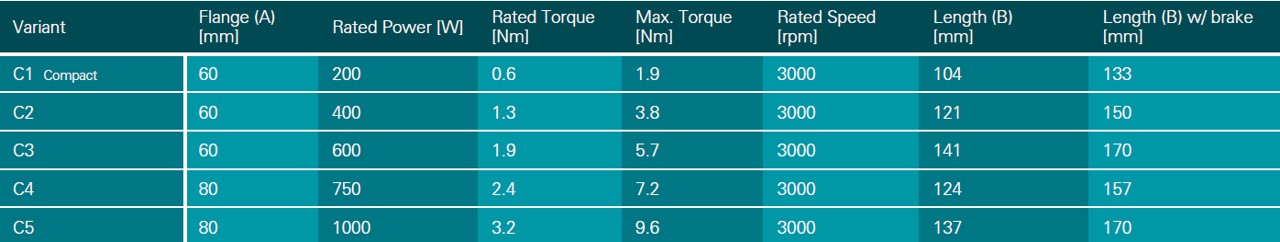

The new ACTILINK family of integrated servo motors replaces several parts and functions in one servo axis and is available with five basic models to cover a power range up to 1000 W and a torque range up to 3.2 Nm.

Overview of the possible variants