High-Efficiency SMT

AC/DC Converters

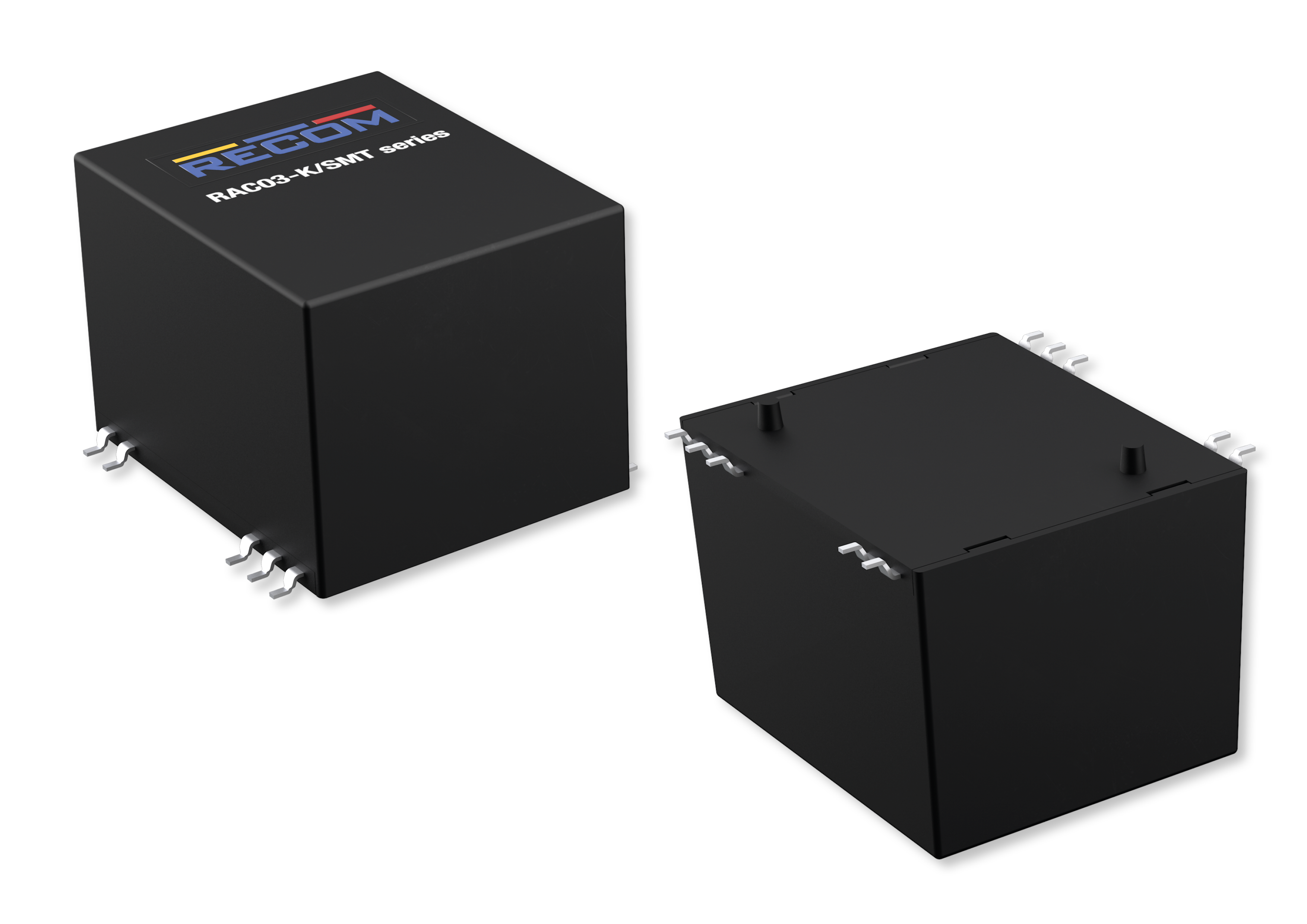

Board-mounted AC/DC converters have traditionally been limited to through-hole technology,

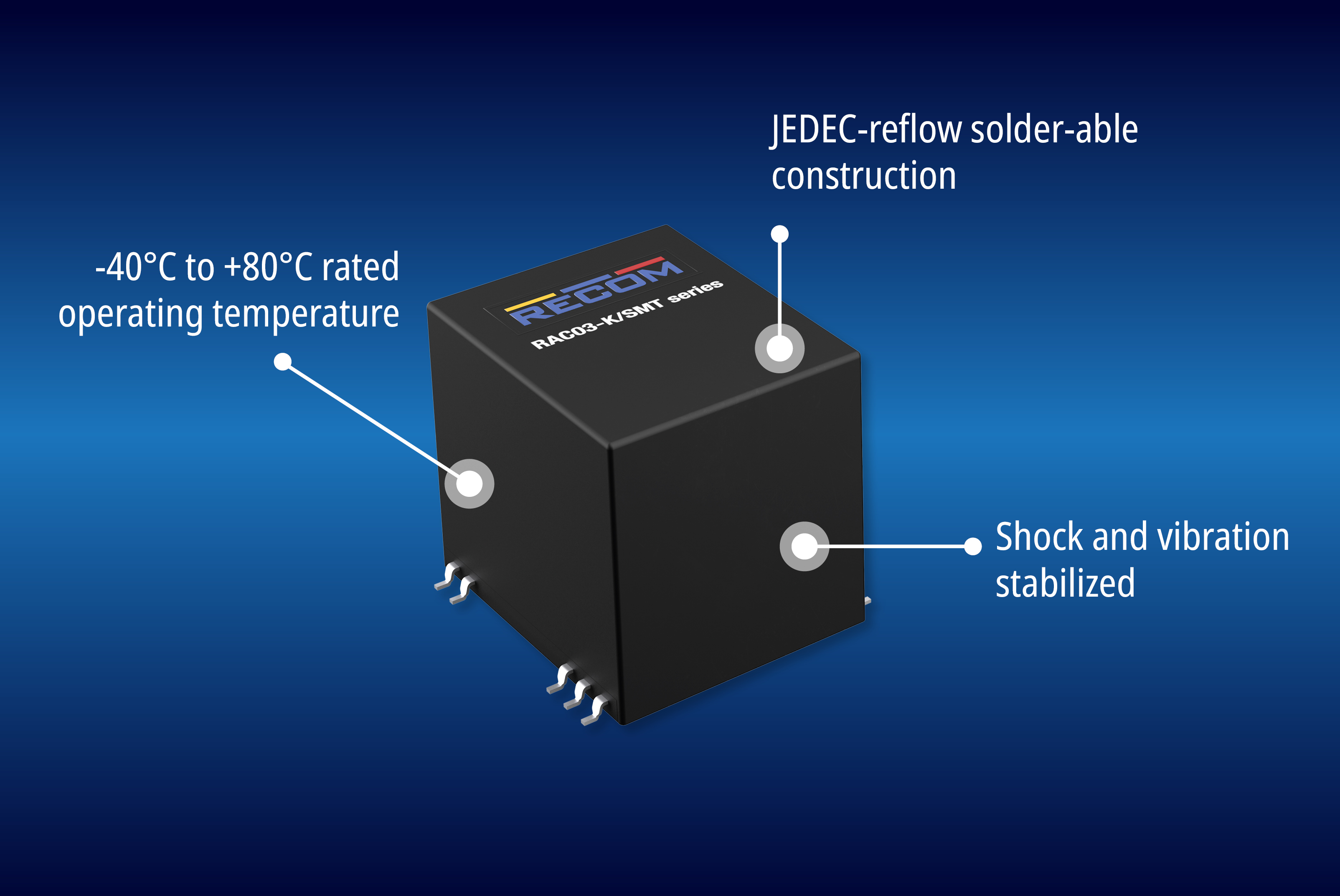

but RECOM now simplifies automated assembly with surface-mount parts that meet JEDEC reflow standards.

The cost-effective RAC03-K/SMT series offers 3 W output options at 3.3, 5, 12, 15,

18, or 24 VDC from a universal AC input of 85 to 265 VAC (120 to 370 VDC), all within

a compact 27.7 x 27.83 mm footprint with ‘gullwing’ SMT terminations and a 19 mm height.

These parts operate at ambient temperatures up to 60 °C without derating (50 °C for 3.3 V

and 5 V outputs), and up to 80 °C with reduced power.