Special Sensors

Intelligent electronic skin

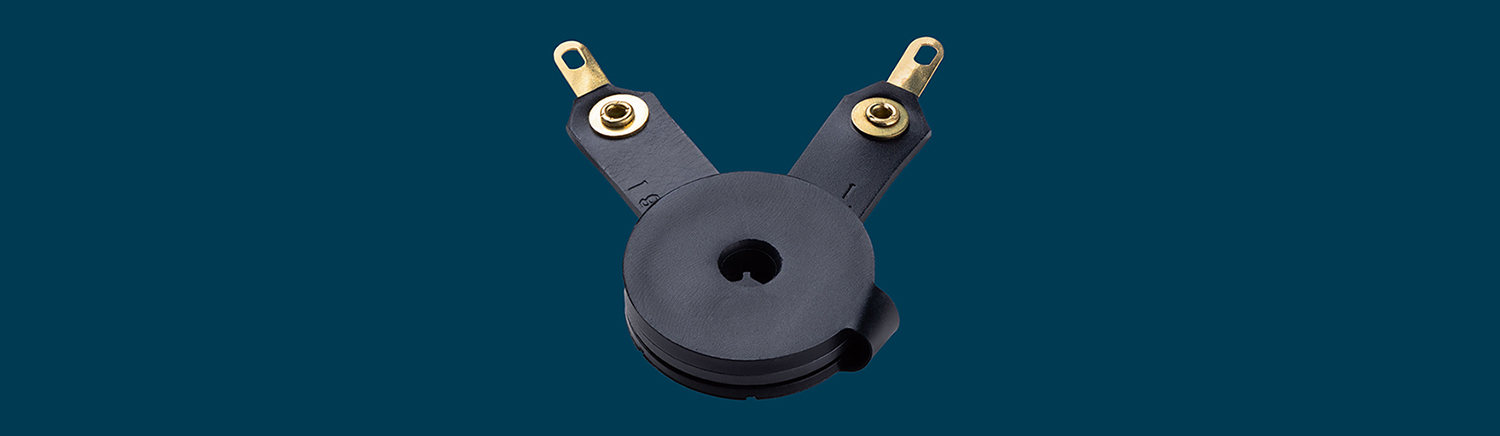

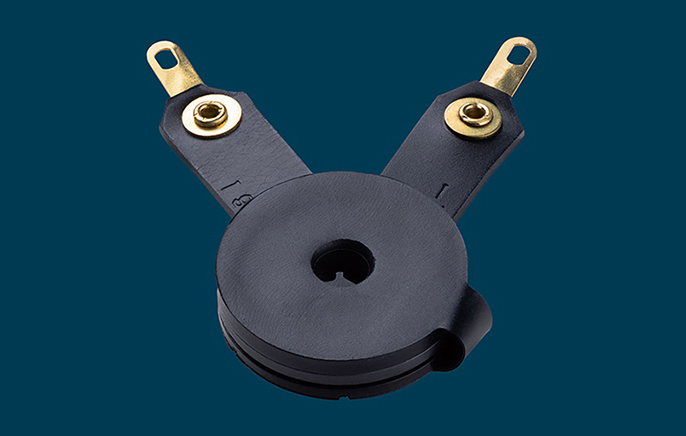

Capacitive silicone force sensor SXTSC1 by Sateco

Through its subsidiary, Sateco XT AG, Sateco is breaking new ground and adding the capacitive

silicone sensor SXTSC1 to its portfolio of established keypad systems. The elastomer sensor works

according to the capacitive operating principle and can continuously measure both touch and

compressive force.

The SXTSC1 silicone sensor is available in different variants.

The dimensions can be adapted project-specifically

The dimensions can be adapted project-specifically

Den

The SXTSC1 silicone sensor is available in different variants.

The dimensions can be adapted project-specifically

The dimensions can be adapted project-specifically

The sensor is soft and flexible, can be shaped three-dimensionally, and is suitable for various applications

such as automotive, VR, AR, gaming, robotics, medical technology, and general industry.

Both the sensor's footprint and dimensions can be freely designed. As a result, it can be customized to curved

surfaces and integrated seamlessly between the body structure and surface. This enables an ergonomic design of

input devices, prostheses, and exoskeletons both on small and large surfaces.

Novel operating and

The sensor combines two measurement functions in one component. It can detect the approximation of a body part

at a short distance and precisely measure its exerted force as well. This keeps the combination compact and

enables predictive operating and measurement systems. Silicone is gentle on the skin. Optional texturing of the

surface can make it even more comfortable to wear. Silicone is chemical and temperature-resistant with regard to

food. When used as a measuring cell, the sensor can be easily integrated directly in the surface away from a

circuit

board using electrical connectors.