Linear shaft motor servos are somewhat unknown in the mechanical engineering market. They have typically been

deeply embedded in high-precision OEM systems that handle lithography, wafer scanning and optical inspection

applications. However, in the semiconductor automation sector, their ultra-precision capabilities make them the

engine of choice. What are their advantages?

No Cogging

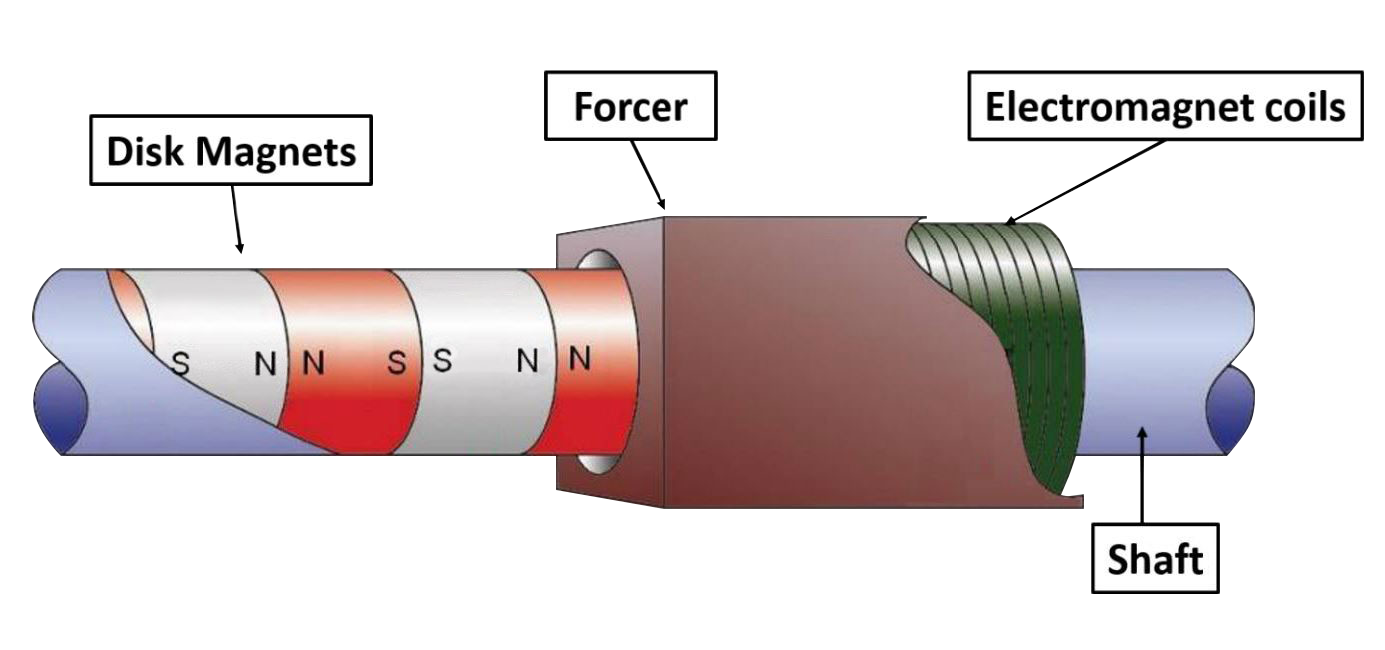

Applications that require precision in the nanometer range require a latch-free motor. The cogging torque occurs

in flat linear motors where the iron core of the motor coil (forcer) reacts with the permanent magnets of the

magnetic path or track. This pulling into the preferred position of the motor (latching) causes both power and

speed ripple during movement.

This is highly undesirable in applications where an absolutely uniform, ripple-free speed or force is required

by the motion profile. Neither in the shaft nor in the driver of the NPM motor is iron present, which ensures

high precision and latch-free behavior. The coils themselves form the core and thus give the motor the

stiffness.

The linear servo motors are contactless. Since the coil wraps completely around the magnets, the magnetic flux

density is used effectively. This allows a large (0.5 to 5 mm) ring-shaped nominal air gap. This air gap is not

critical, in the sense that there are no changes in force in this area.

In conventional linear motors with iron cores, this ensures large absorption forces between the stator and the

fitting and leads to cogging moments in linear movement. U-shaped linear motors, on the other hand, use an epoxy

core that does not generate eddy currents or receiving forces.

The linear servo motor is designed for motor

stiffness that is 100 times higher than that of a U-shaped motor with four times greater heat dissipation than

similarly sized flat linear motors.

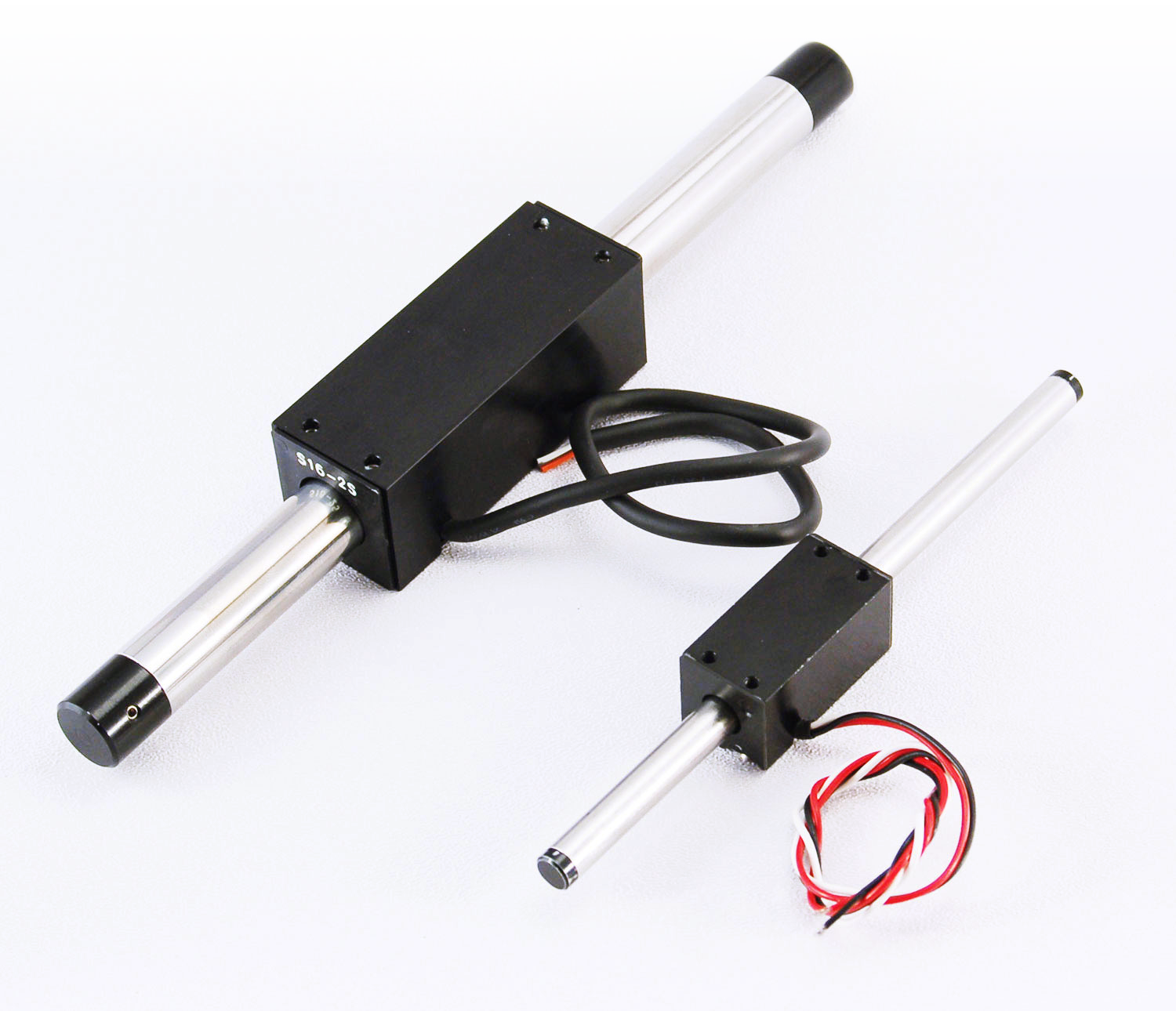

The linear shaft motor can be much more than a replacement for

pneumatic cylinders