Electric steam generators are one way of reducing the CO2 footprint. Whether in the health sector, chemical,

pharmaceutical, automotive or food and beverage industry, the steam generators of Certuss

Dampfautomaten GmbH & Co. KG supply steam and process heat worldwide. Steam and heat are

indispensable in many industrial processes such as cooking, sterilizing, or drying. A failure

in steam generation can therefore lead in many sectors to the shutdown of entire processes and

have serious consequences. “Steam provides the basis for the entire process of each of our customers,”

explains Thomas Hamacher, managing partner and technical manager at Certuss.

Electrically driven steam generators increasingly more important

The highly compact steam generators of the family-owned company based in Krefeld

were for a long time mainly driven with gas and oil. However, Certuss and its customers

have recently been increasingly using electrically driven steam generators, which can

also operate more sustainably. Customers have also been requiring steam generators that

are compact and easy to maintain.

Certuss has met the demands of all three trends with

its new EMX product series. Considerable importance is placed here on the availability

of spares and the fast accessibility of service personnel. “For the customer, the supply

of steam must be as convenient and reliable as the supply of electricity from a power outlet,”

explains Thomas Hamacher. “Ideally, the customer is hardly aware of the location or function of

the steam generator.”

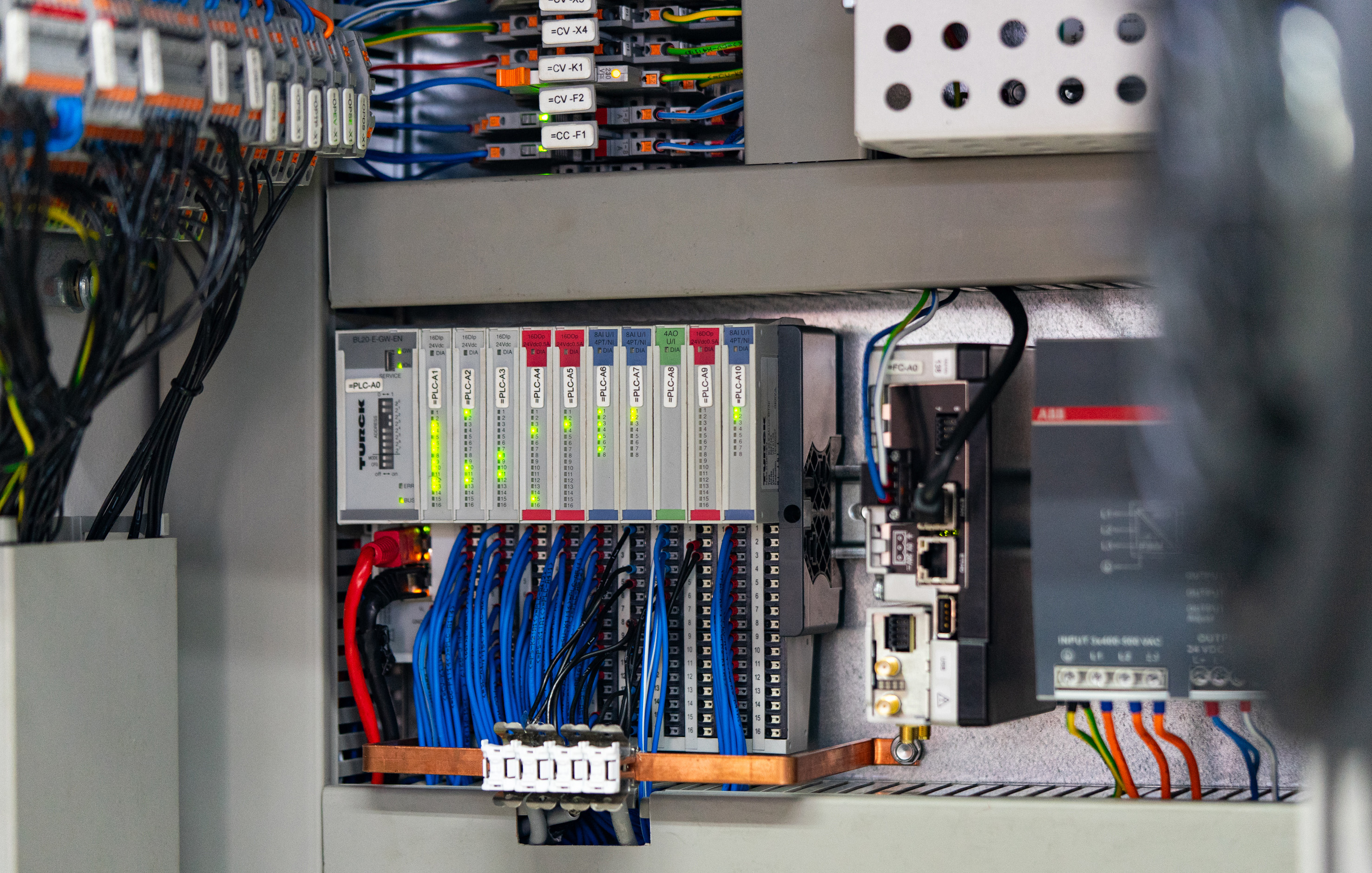

Modularity, space saving and remote monitoring

The electric steam boilers of the EMX series can be expanded in modules. Thanks to

their upright design, they can be combined into space saving assemblies. The main module

can be expanded with additional units if the requirements increase.

Certuss has also

equipped the systems with an online connection for monitoring system status remotely.

The measured data provided by the pressure transmitters is routed to the BL20 I/O system