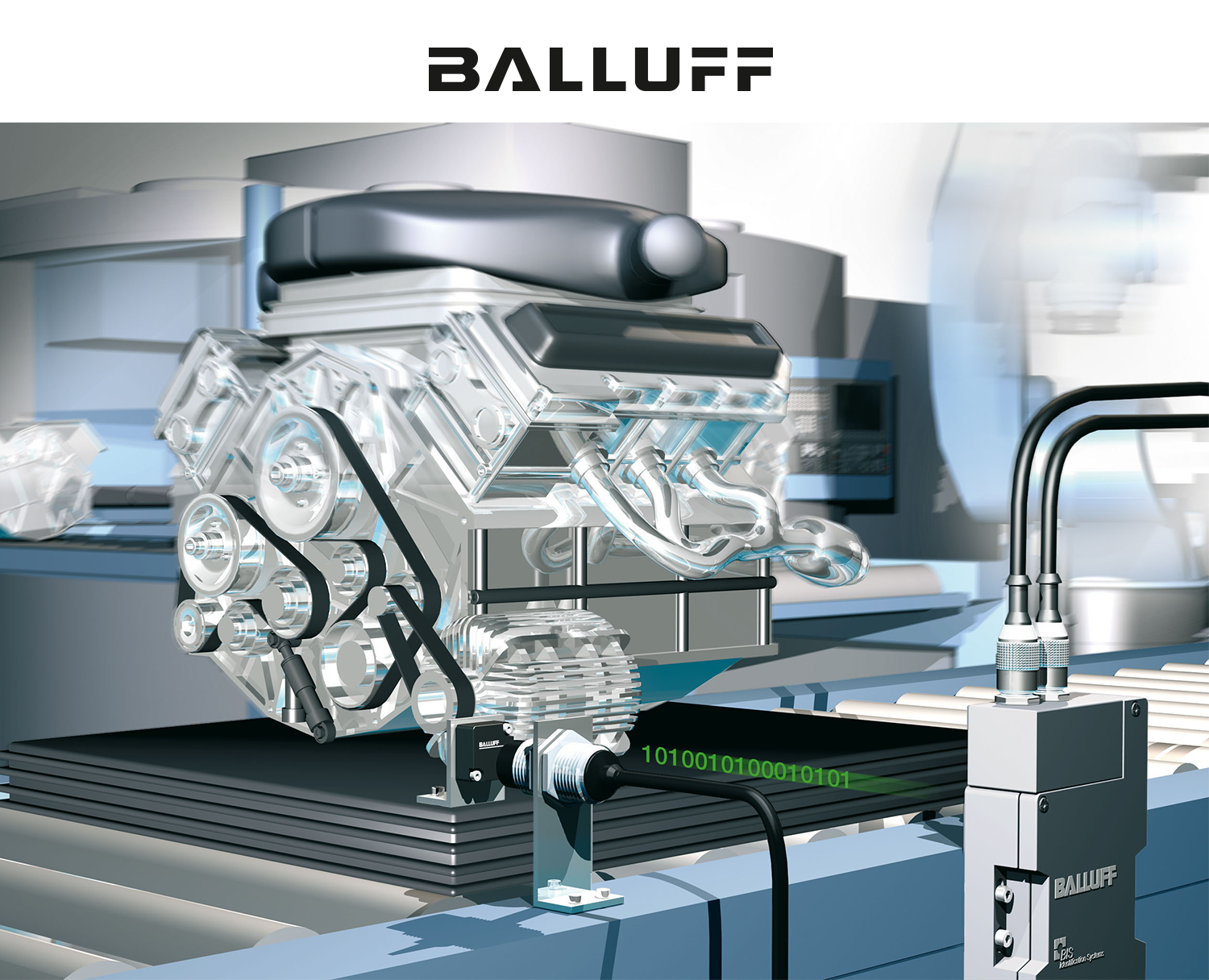

Tool-ID and workpiece tracking come together

RFID systems with various frequency ranges are finding increasing use in modern production and assembly

plants. Each system is designed for different applications. Low-frequency (LF) systems are suited mainly for

applications in metallic surroundings. High-frequency (HF) systems are the ideal choice where a greater

read/write distance and high speed are paramount. Since each system until now required its own RFID controller type, this was not only cumbersome but also expensive for the user. With the BIS V All-in-One

RFID processor from Balluff the situation has changed. This model represents the best of both worlds, since

it allows up to four read/write heads to be operated simultaneously regardless of whether LF or HF.