High-density and miniaturization in fan design

Today’s equipment requires quality fans with high static pressure capabilities, which are optimized to

raise the cooling efficiency. The criteria for differentiation of fans includes a list beginning with motor

design, the slot-pole combination for efficiency and power saving. Material selection calls for long life,

the use of magnets and plastics and a strong housing. An efficient design method is also needed for low

acoustic noise.

Dynetics assists engineers across Europe in selecting cooling equipment, axial instrument ventilators and

radial blowers from various manufacturers. One of which is Nidec Servo using new techniques such as

Computational Fluid Dynamics (CFD) design technology.

Nidec Servo selected a three-phase brushless motor and immediately saw a 10 per cent increase in efficiency,

compared to a single-phase motor. Further improvements were realized by increasing the diameter, making the

motor more powerful.

By using SmFeN instead of ferrite as magnet material, the magnetic flux increased by a factor of 1.4, and

the higher HFe (high ferrite) magnet material prevents demagnetization, reports the company.

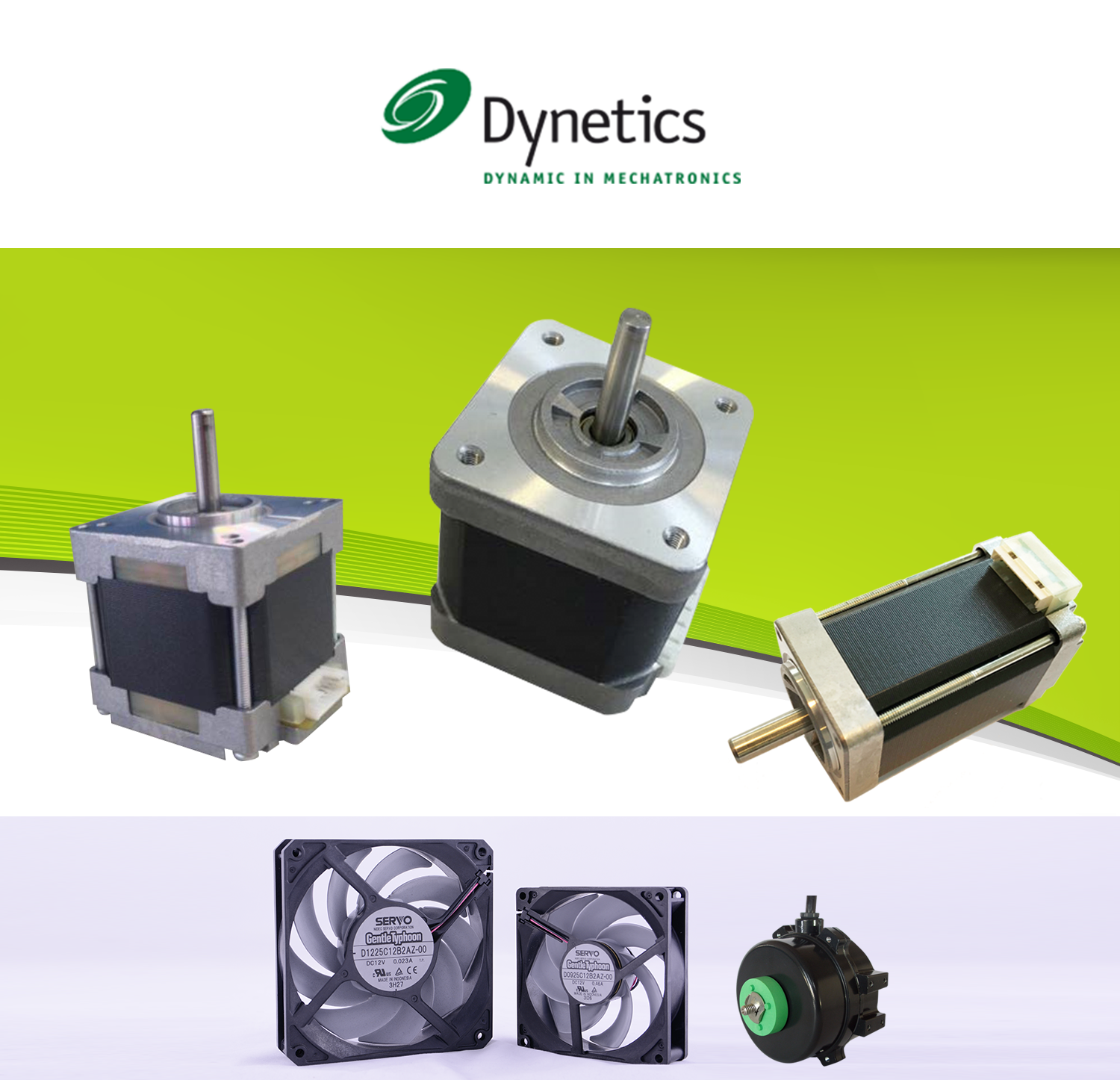

The G-series fans are cUL/TUV-approved and offered in plastic or aluminum housings

The fan blades are made of polyphenylene sulfide (PPS), preventing the deformation at high speed at high

temperature.

For high static pressure applications, diagonal flow fans, (which expel air in a centrifugal direction) or

two axial fans mounted in series, are usually considered. However, these offer disadvantages due to the

direction of air-flow, physical size and cost.

Innovative design techniques for fan blades using CFD are applied to the design of rotor cascades for

low-noise fans. The special shape of the fan blade, reflects not only in a better result in airflow, but

also in

a low noise level.

Using this system, Nidec Servo has developed its G-series axial fan range to meet both high level

performance requirements and specific application demands.

By using the fan optimization design system, Nidec Servo developed a new version of axial fans, which offers

high static pressure performance and more airflow without compromising in size and noise level.

The cUL/TUV-approved, high performance, ball-bearing fans are suitable for use in the industrial and the IT

markets. The new models come in a choice of popular frame sizes, namely 80 x 80 x 38 mm, 92 x 92 x 38 mm,

120 x 120 x 38 mm

and 134 x 134 x 38 mm. They are offered in a range of DC voltage (12, 48 and 54 V) options, depending on the

model. The fan housings are available in plastic or aluminum.