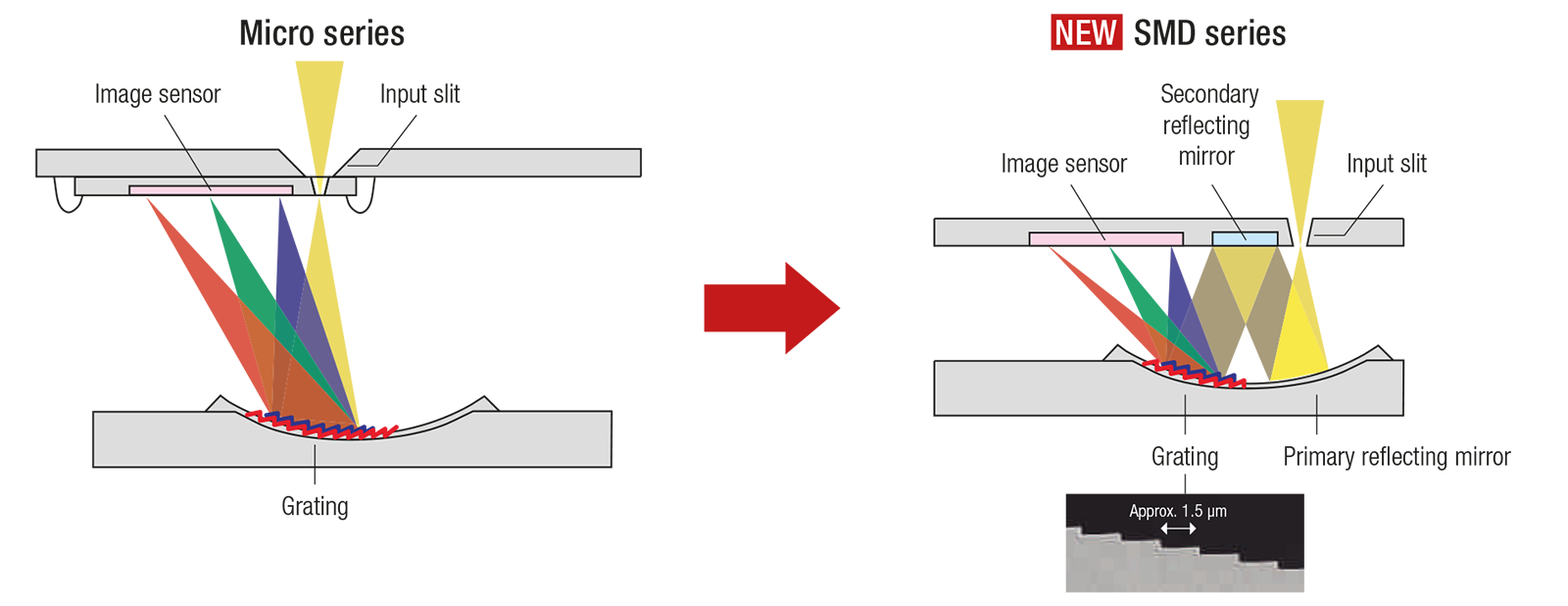

Optical system layouts

Realizing smallest structures

The world's smallest grating type spectrometer was made possible through the integration of the unique optical design technologies developed by Hamamatsu Photonics and the MOEMS technology (MOEMS = Micro-Opto-Electro-Mechanical Systems) that achieves high quality in mass production. In a grating type spectrometer, the positional relationship is important between the slit passing the light in, the grating separating the light into each wavelength, and the sensor.However, the process of micromachining gratings was approaching its limits using the previous structure for minimizing the number of reflections in order to achieve the needed accuracy. To overcome this limitation, the SMD series was developed with a completely new approach.

Ultra-miniaturization was accomplished by employing optics using multiplex reflection that utilizes MOEMS technologies such as replication technology that replicates submicron-level shapes through nanoimprints and high-added-value CMOS sensor technology that integrates a slit and mirror. In addition, the latest high-sensitivity image sensor has successfully increased the sensitivity even further. ▪ ds

Find out more now!

SENSOR+TEST 2019

Hall 1, Booth 312

Nuremberg, June 25-27

Laser – World of Photonics 2019

Hall A2, Booth 303

Munich, June 24-27