Traditional, or “rule-based” machine vision performs reliably with consistent and well-manufactured parts and

excels in high-precision applications. Those include guidance, identification, gauging, and inspection, all of

which can be executed at extremely fast speeds and with great accuracy.

This kind of machine vision is great

with known variables: is a part present or absent? Exactly how far apart is this object from that one? Where

does this robot need to pick this part? These tasks are easy to deploy on the assembly line in a controlled

environment. But what happens when things aren’t so clear cut?

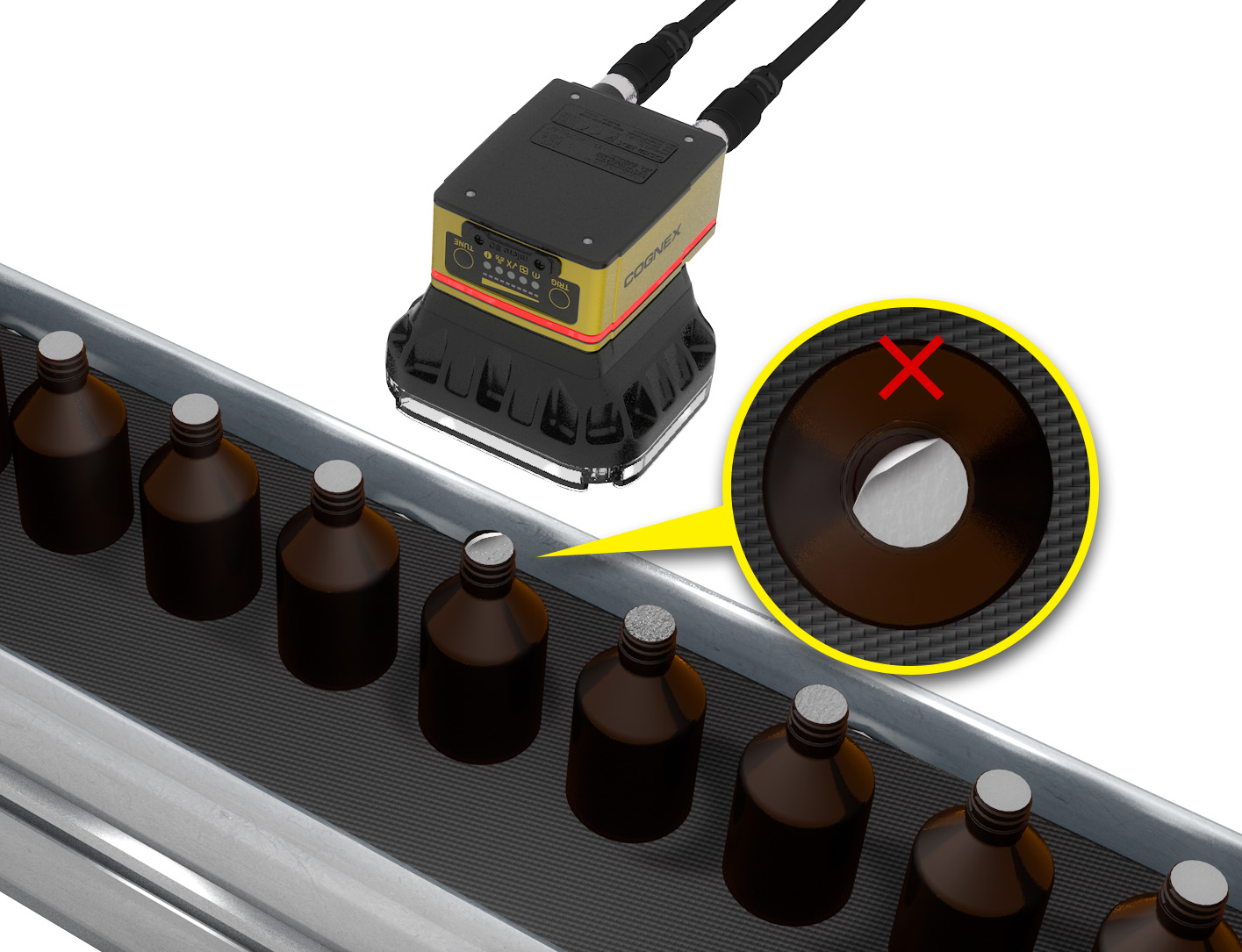

Inspection of bottles for correct sealing

Deep Learning

complements machine vision

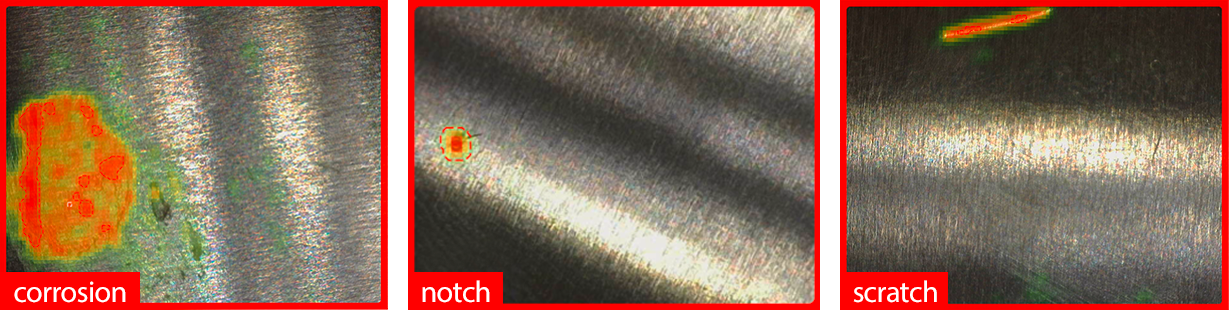

Deep learning is the solution in such cases. It uses example-based training and neural networks to analyse

defects, locate and classify objects, and read printed markings. By teaching a network what a good image is

based on a set of labelled examples, it will be able to tell the difference between a good part and a defective

one, considering those expected variations. The following considerations can help factories and manufacturers

who are new to deep learning avoid costly missteps and lost time, while generating organizational buy-in for the

technology’s considerable upside. If done properly, the first successful project can lead to a more ambitious

and strategic rollout. Here are five areas to consider before deploying your first deep learning pilot project.

Setting proper expectations

A well-trained deep learning application requires a comprehensive set of training images that represent a range

of defects and/or acceptable part variations to perform well in production. Those images also need to be

acquired under manufacturing lighting and part presentation conditions. This is essential for any deep learning

project to become successful. Additionally, once images have been collected, they will need to be properly

graded and labelled.

In other words, a quality expert needs to be involved in any project from the get-go.

Qualifying a deep learning vision solution is an iterative process that requires the system to be installed on a

production line. And, unlike traditional machine vision systems, training, and validation of the images for deep

learning must be done during the development phase – it cannot wait until factory acceptance testing. Deep

learning requires a great number of samples to train with, which could require time to capture the

representative set of images needed to train a well performing deep learning tool.