Highly precise scans offer maximum performance for industrial applications

With its quad-camera technology, the high-performance PowerPICK3D sensor achieves top speeds and empties pallet

cages in no time. MiniPICK3D, on the other hand, is optimized for components with edges just a few millimeters

long, meeting even the requirements for applications in the disciplines of fine mechanics, electronics, toys,

and comparable industries. These new sensors for fully automated bin picking complement the successful

IntelliPICK3D product line, whose robust component detection impresses even under the most difficult of

conditions. With an embedded PC, the design does not require any extensive wiring between the camera and the PC,

thereby ensuring the easiest possible installation and commissioning. In addition, the embedded design enables

maximum speeds for data transmission. Users, therefore, benefit from extremely short scanning times. The

individual design of the systems focuses on the fastest possible cycle times, maximum process reliability, and

top speed.

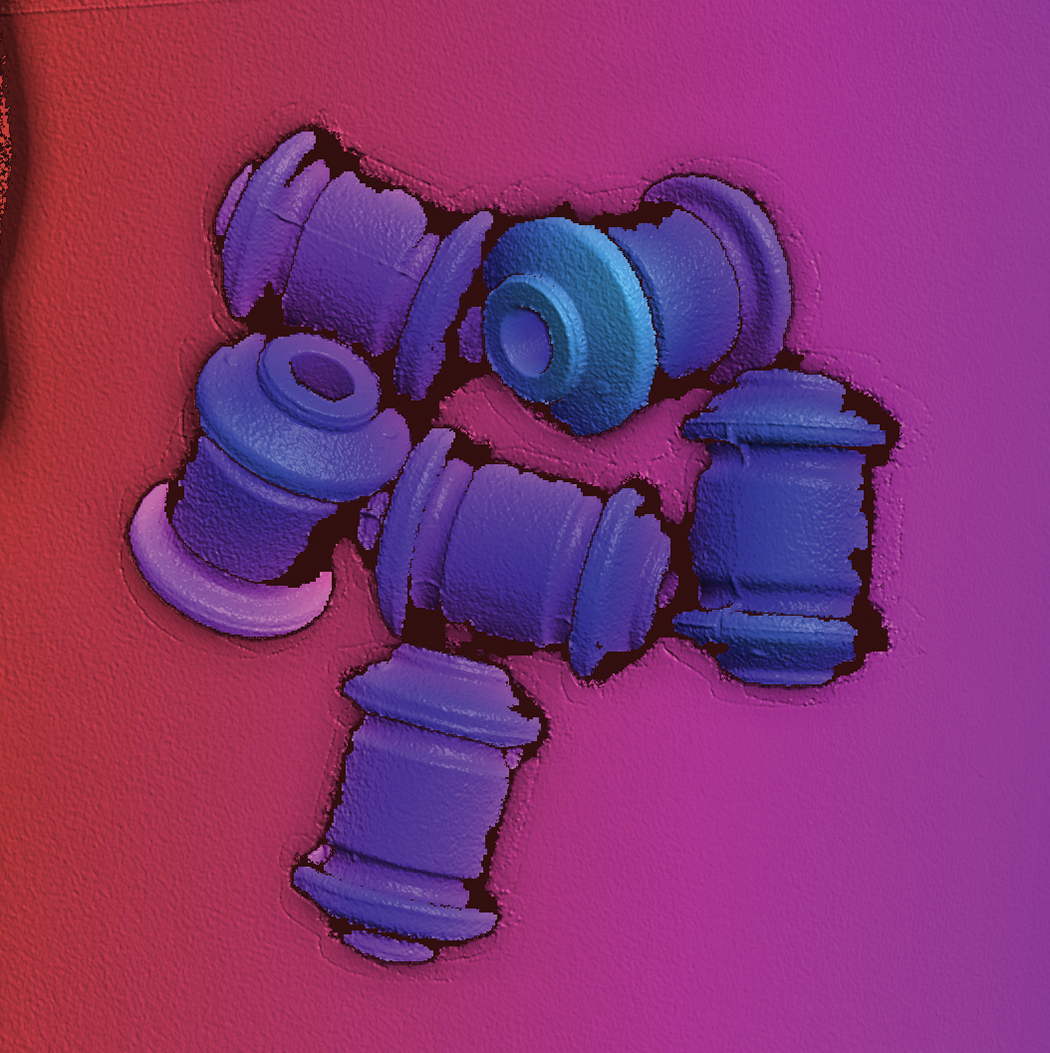

Full monitoring under the toughest conditions – with IntelliPICK3D-PRO

Developed based on IntelliPICK3D, the IntelliPICK3D-PRO was specifically designed with the tough conditions on

production lines in mind. Its powerful laser lighting ensures detailed image capturing with a high depth focus

even at great distances from the container, in incident light, and under other difficult conditions, while still

being safe for the human eye. Parts are reliably detected and picked even in complex locations. The system

detects dirty surfaces as reliably as glossy or matte components. Intelligent collision avoidance automatically

plans the correct picking path to ensure smooth operation. A software extension means that the system now also

tolerates different container positions and types, supplying the production line without interruptions and with

high process reliability.

IntelliPICK3D-PRO

IntelliPICK3D-PRO

With its robust laser illumination, IntelliPICK3D-PRO reliably captures the most complex geometries,

even under

challenging production conditions