A linear positioning device usually uses a spindle or a ball screw. A spindle is a threaded shaft on which a

simple threaded nut travels. Ball screws use the spiral angle of the thread to convert rotational motion into

linear motion. The nut is attached to a load – a movable table or cart – so that when the shaft rotates, the nut

and load pass in one direction or another. The shaft can be rotated by a motor.

The function of

ball screws

A ball screw drive, also known as a recirculating ball screw, is a mechanical linear drive that converts a

rotary motion with high efficiency into a linear motion with low friction. It consists of a screw spindle and a

nut integrated with rolling elements that cycle through a return mechanism. In most cases, the spindle is

rotated and the nut is connected to the part to be moved. In some cases, the nut is also driven and the spindle

performs the linear movement.

Linear ball screws are used in a wide variety of applications, but some of the most demanding are those at the

extreme ends of the performance range - large diameters on the one hand, or small diameter linear ball threads

and very fine performance for optical and medical applications. For very small, high-precision movements,

developers often turn to miniature ball screws.

In general, a distinction is made between ground and rolled ball screws. In the case of ground ball screws, the

nuts are usually pre-loaded (play-free) or with minimal play (0.005 millimeters). The high surface quality of

the ground tracks also reduces noise in operation.

Differences between the

various size classes

Although there is no industry standard that classifies a linear ball screw drive as "miniature", most

manufacturers apply this designation to spindles with a spindle diameter of less than 16 millimeters. Spindles

with diameters less than 6 millimeters are sometimes called "sub-miniature" or "ultra-miniature".

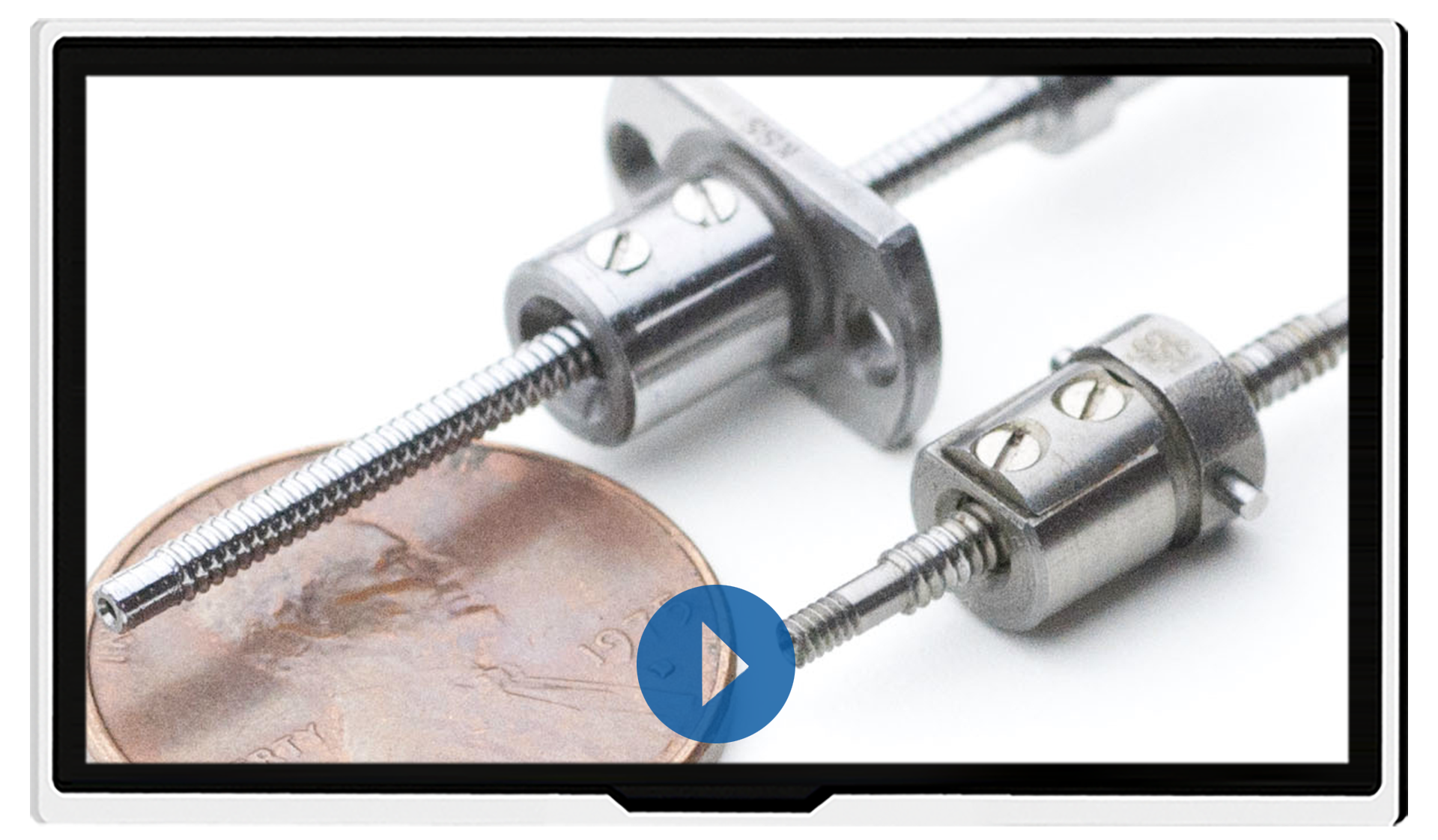

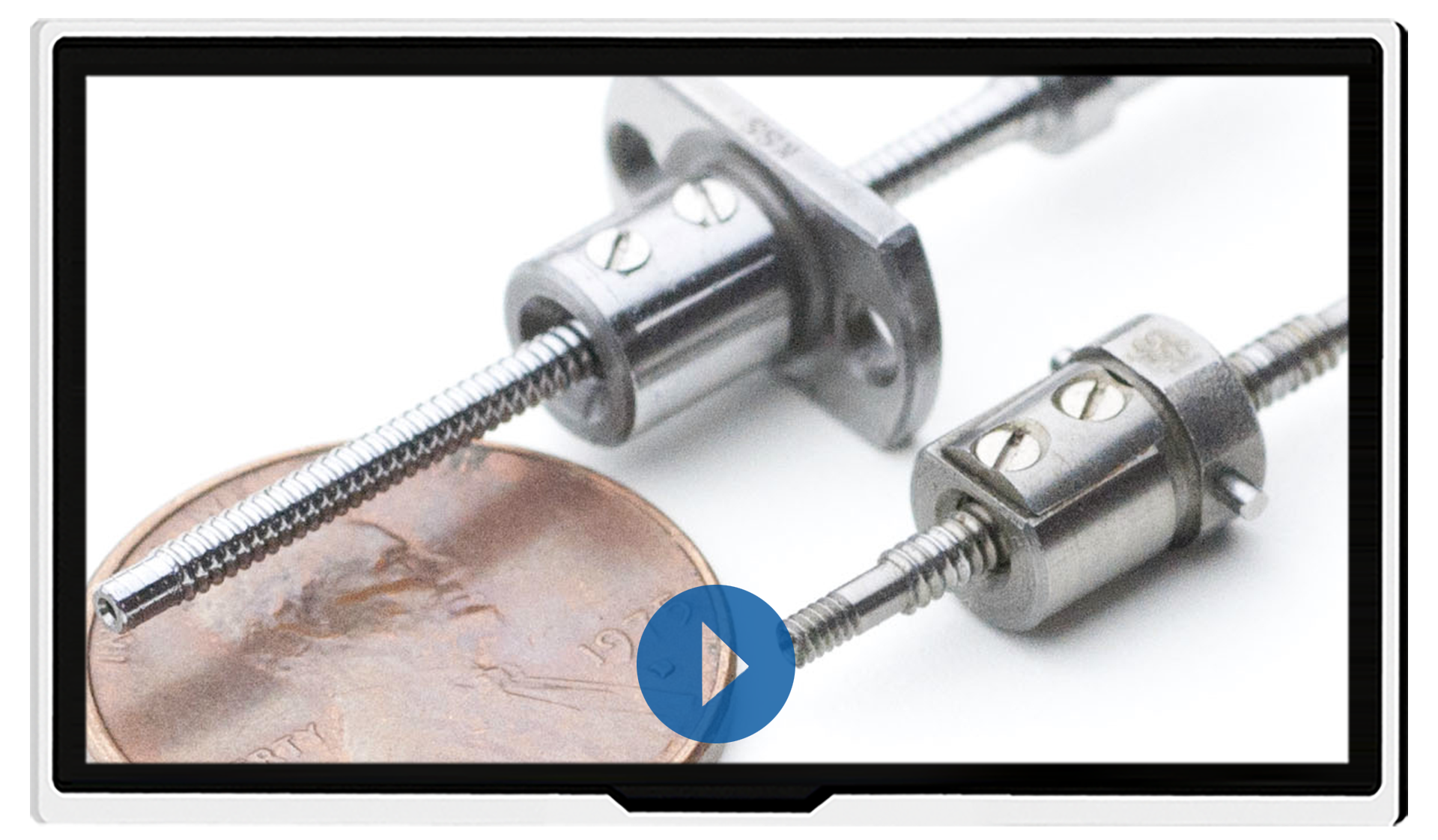

Video: KSS World's top class technology of making the

smallest Ball Screw