The production monitoring solution delivers context-specific information for various roles on the shop floor:

Machine operators, production managers, and other users always have access to the information that is

relevant for them. Notifications of pending tasks for example, information about production KPIs, or

specific help with troubleshooting and fault elimination.

in-tech has developed easy-to-use production monitoring solutions based on the smartConnect modular system

for the machine manufacturer ASM and the metrology specialist Wenzel.

ASM is the worldwide leading supplier and partner for electronics manufacturing.

The company produces, among

others, printers and placement solutions for electronics production.

One of the challenges is achieving the most efficient use of the machines as possible. High capacity and

short changeover times have to be ensured.

To better support customers in this mission, ASM commissioned

in-tech as a partner in the development of the ASM Performance Monitor (APM).

Optimized production processes thanks to KPI analysis

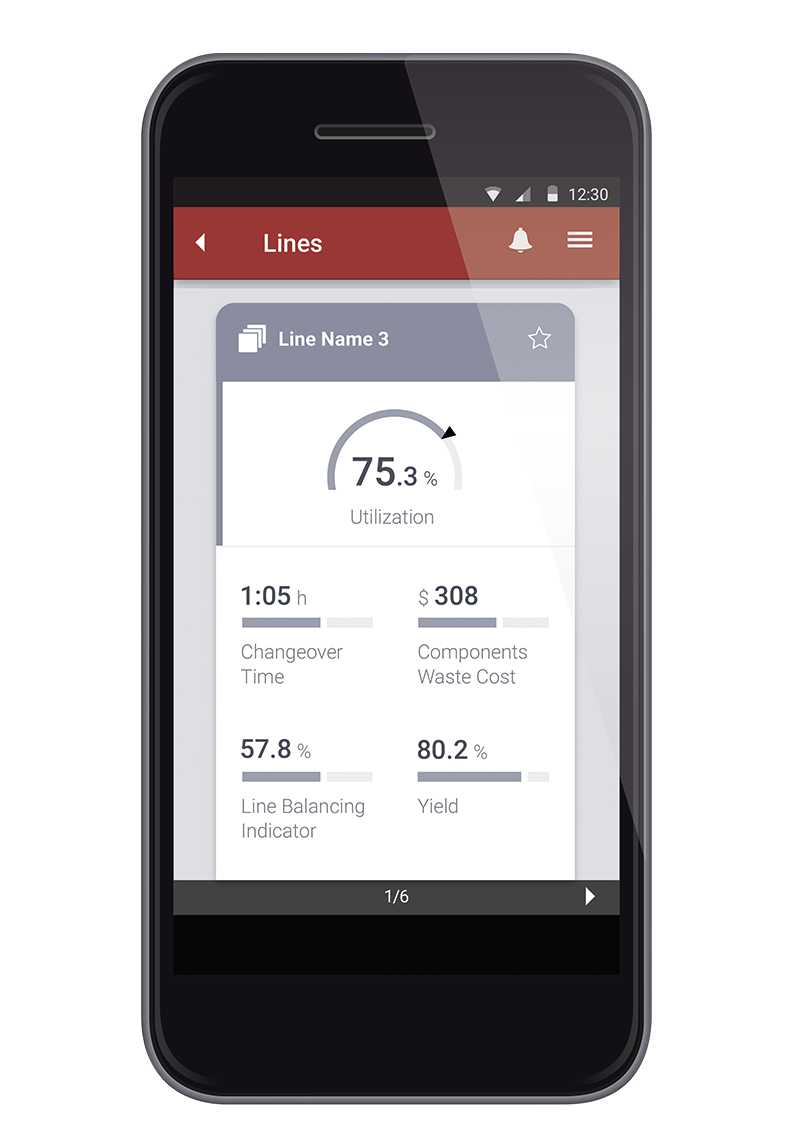

The APM was partly developed based on a modular smartConnect building kit and runs via smartphone, desktop

and info-screen. The solution offers views for different user roles, from the machine operator all the way

to the production manager. Users can see the exact information on the APM that they require at that

particular point in time.

Targeted production analysis

With the APM, production managers receive insight into all important KPIs, such as capacity, performance or

component rejects. This information supports the manager in the analysis and optimization of the production

processes and allows for a more efficient introduction of new products.

Also available on the mobile device: all important key figures, evaluations and warnings

Performance monitoring

While production is underway, the APM allows the production manager to set the current production goals and to analyze the current capacity and productivity.