Balluff SmartCamera

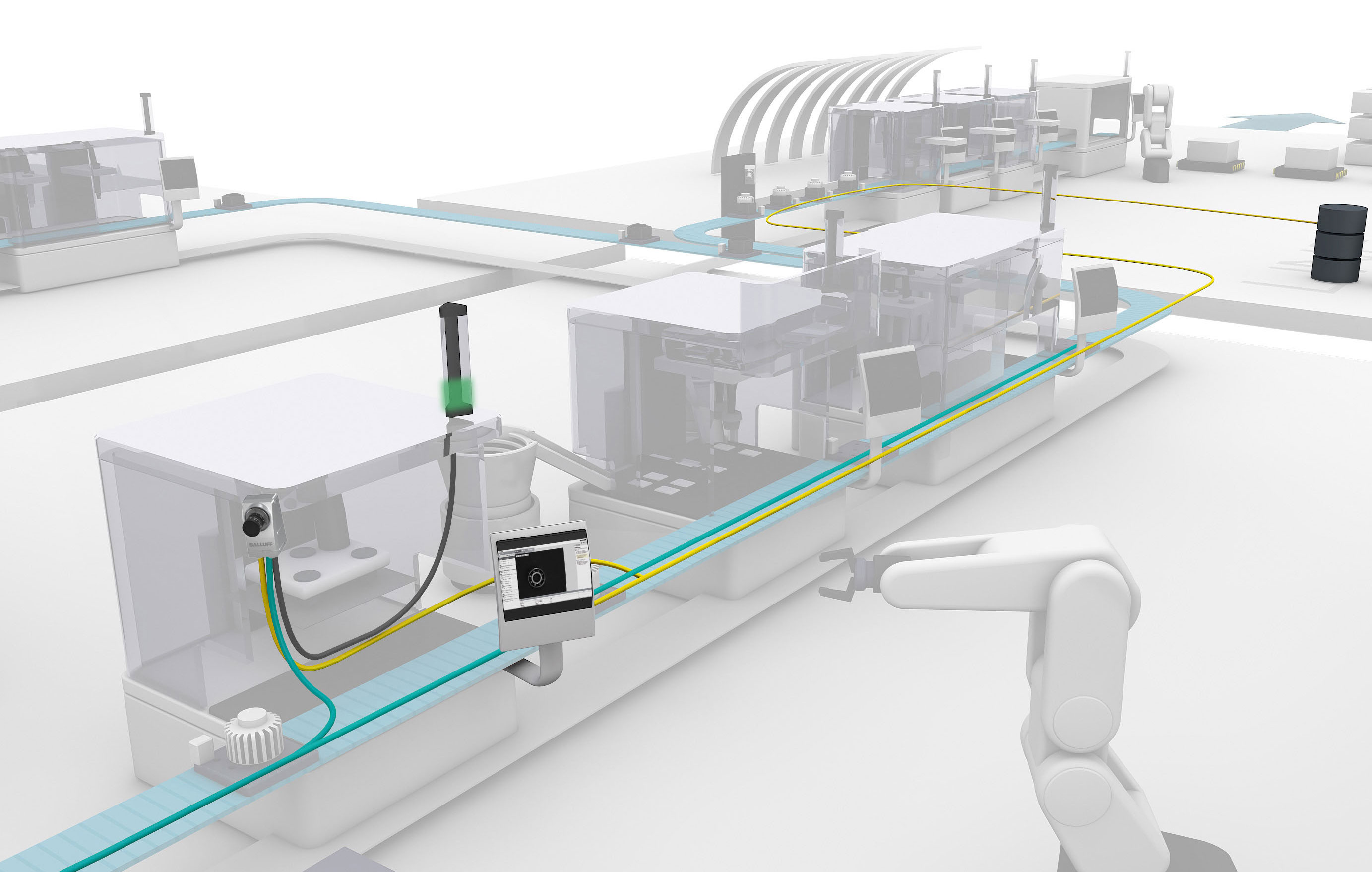

Intelligent data management contributes to stable production processes

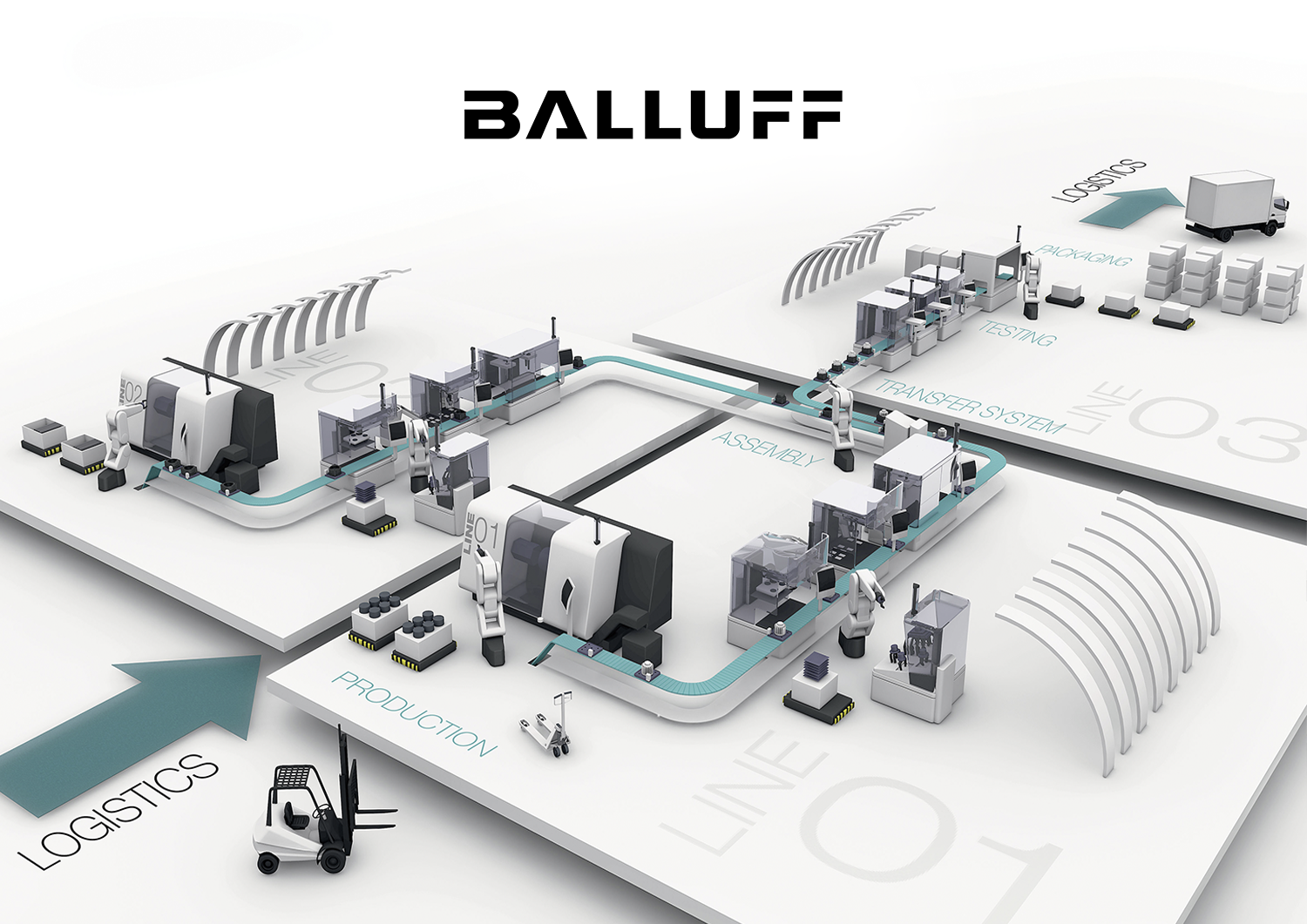

Industry 4.0 – the smart, adaptive factory with short retooling times and decentralized control – aims to

generate the most comprehensive data possible within a highly automated process in real-time and provide the

most varied instances possible. This status information in the form of process data for control and

monitoring of sequences and product data for traceability and quality verification form an objective basis

for making decisions in order to take early measures for process optimization.