Ultrasonic sensors are the optimum solution for many applications where space is restricted and in which

sensors are used for distance measurement or similar metrics, as they offer here several benefits compared

to other solutions. An optical sensor is subject to dirt so that the user has to regularly clean it.

Ultrasonic sensors on the other hand are insensitive to dirt, dust and even water. They always offer

reliable operation. Ultrasonic sensors also detect every object, irrespective of the structure and color of

its surface – another critical benefit compared to optical sensors.

However, ultrasonic sensors are not only superior in many respects to optical sensors. Unlike inductive

sensors, which only detect metals, ultrasonic sensors can detect any medium.

This also applies to plastic,

which makes them also one step ahead of capacitive sensors. Capacitive sensors are also several times more

susceptible to dirt than ultrasonic sensors.

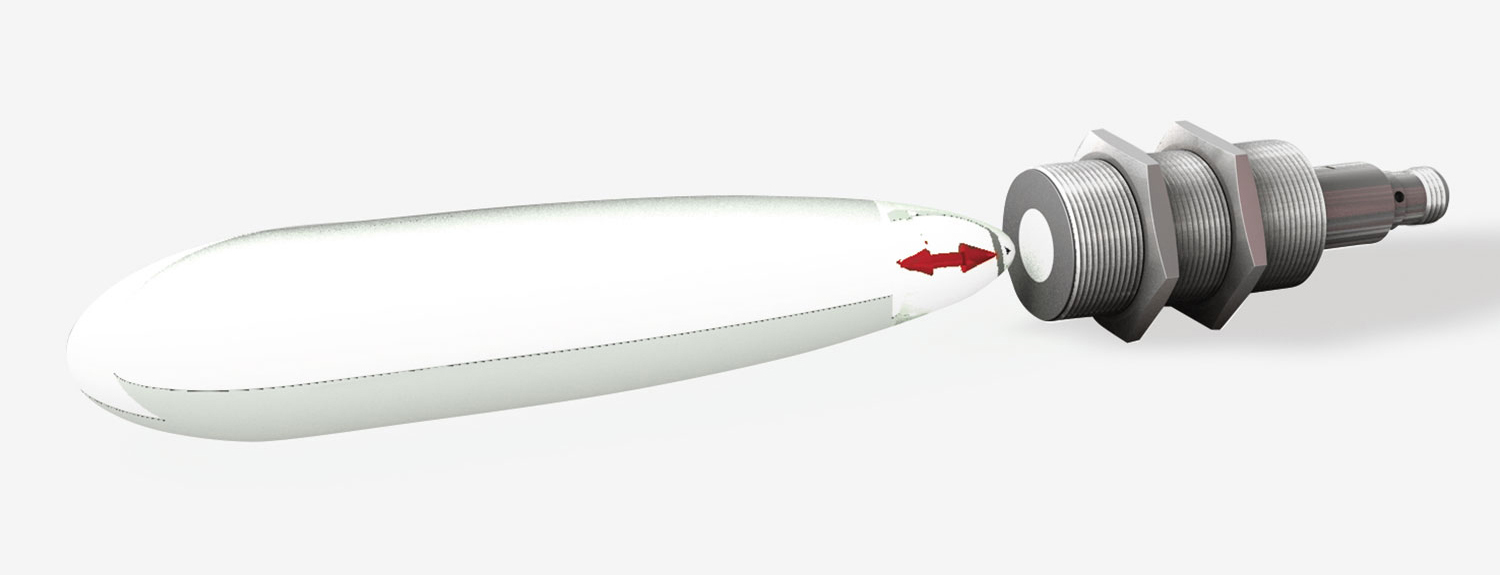

Ultrasonic sensors from Turck - robust, compact, self-cleaning

Turck's ultrasonic sensors have all these features – and more. Their highly robust housing with a continuous

threaded barrel entirely made of metal is particularly short and stands out on account of a metal connector

which is manufactured as one piece with the threaded sleeve. This eliminates any potential weak points that

could cause damage in harsh environments and at low temperatures. The thread runs over the entire length of

the sensor so that the mounting position can be varied as required within the mounting bracket. The

connector can also not break off since it is made entirely of metal. Turck ultrasonic sensors also have a

smooth sonic transducer front, which reliably prevents contamination and the formation of particle deposits.

The mechanical movement of the membrane even shakes off deposits and is thus virtually self-cleaning.