The shortage of skilled workers is causing particular problems for small

and medium-sized enterprises. Around 75 percent of entrepreneurs worldwide

have reported difficulties filling their vacancies in 2022 [1]. In the skilled

trades companies in Germany alone, there was already a shortage of around 87,000

employees in 2021, and there’s an upward trend. Fields such as construction electrics,

plumbing, heating and air conditioning technology as well as automotive technology are

particularly affected [2]. Most companies know that automation can provide relief.

Nevertheless, SMEs have often been reluctant to use robots. Their arguments: too complex,

too expensive, too much skepticism in the team. But these are just myths!

Robots take

heavy work off colleagues

Anyone who has taken courage and tried it knows that investing in automation is worthwhile.

Because the risk is low. And the opportunities are huge. Whether it's palletizing,

loading and unloading machines, quality control or welding, robots can complement

well-established human teams perfectly. And they master their tasks reliably and precisely.

They take over unergonomic, stressful, monotonous and time-consuming work. Employees are thus

physically relieved and gain time for more high-profile activities. After all, at 35.4 percent,

musculoskeletal disorders are the main cause of incapacity to work in the skilled trades in Germany.

Back pain, shoulder lesions and the like are responsible for the majority of sick days, especially in

the construction and finishing trades [3].

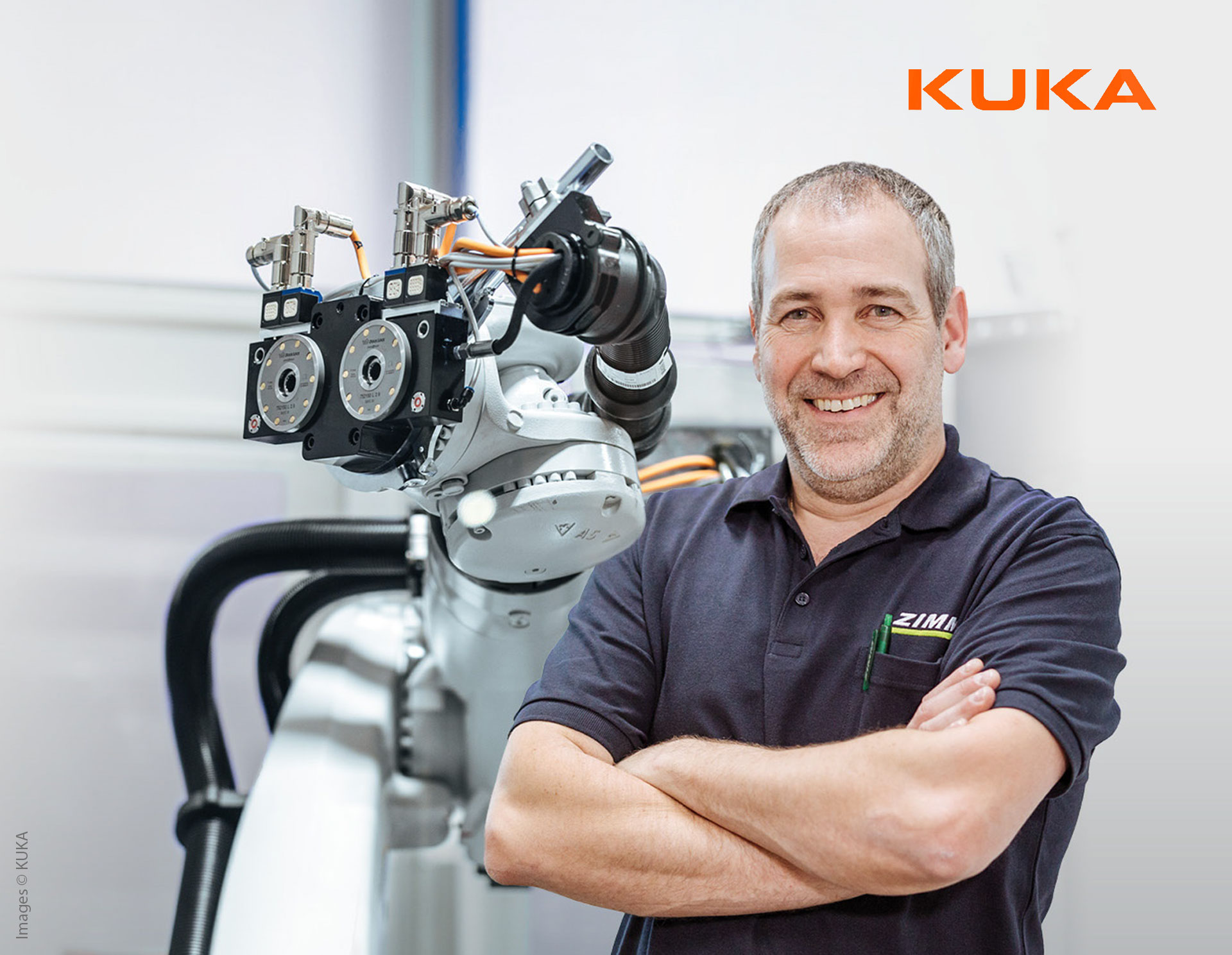

Robots can provide a remedy here, as the example

of the screw jack manufacturer ZIMM Group GmbH shows. The workforce

of around 300 employees is relieved by two KUKA robots. First, a KR QUANTEC

in a cell loads a milling machine with raw metal parts. Once the components have

been finished, the robot places them on the finishing station in the cell. There, a KR

AGILUS deburrs and cleans them. “Automation allows us to produce in unmanned shifts at night

and on weekends, which increases our productivity and competitiveness,” reports Hardy Ponudic,

Production Manager at ZIMM.