The DATAEAGLE

Condition Monitoring System from Schildknecht AG – connect – activate – use

Ready-to-use Condition Monitoring System

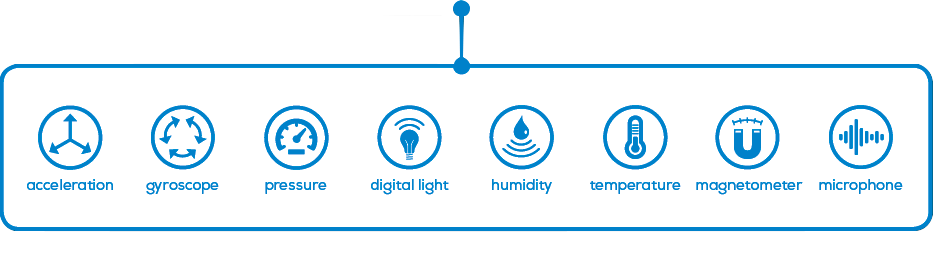

Plug-and-play from sensor to data dashboard

Condition monitoring (CM) has long been known as a method for ensuring high availability of machines and

plants by means of remote monitoring of parameters relevant to the operations. CM is increasingly

becoming a key component of industry 4.0 business models. An example is the CM solution designed by

Schildknecht AG, for radio data transmission and IIoT solutions.