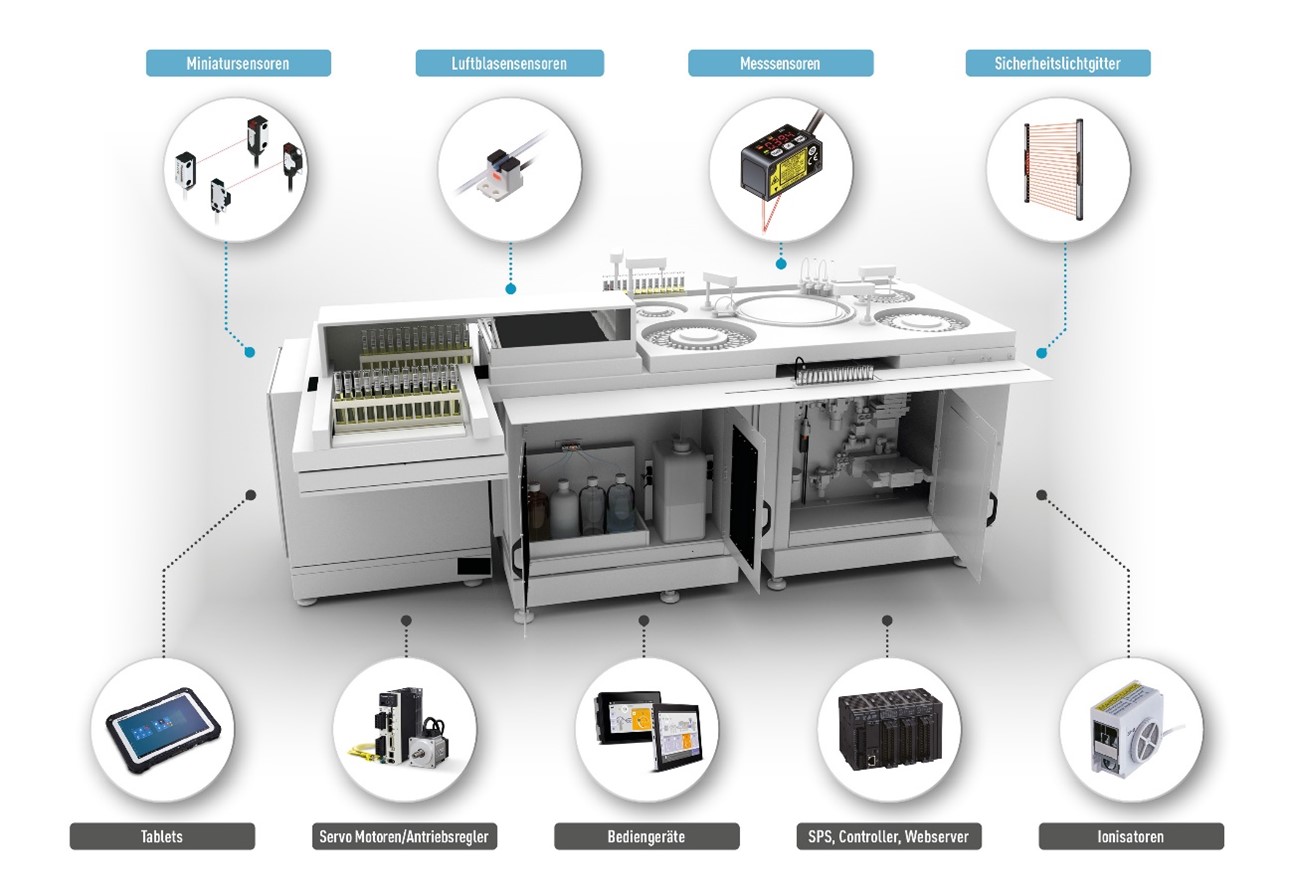

Sensor solutions for laboratory automation

Panasonic Industry offers, in addition to state-of-the-art sensors, a wide range of automation components

such as safety light curtains, controllers, motors, and HMIs (human-machine interfaces) that reliably

contribute to the automation of laboratories.

In this industry, the phrase "Big Data" is more than just a buzzword.

In the future, we will have to deal with new synonyms such as AI (Artificial Intelligence) and IoT (Internet of Things). In the hypothesis-driven lab with the strong driver of sustainability combined with the growth of ever higher quality artificial intelligence and algorithms, there will be more virtual "DMTA" (Design-Make-Test-Analyze) and less tangible ‘make’ and ‘test’.

So what new developments in data management will occur in the hypothesis-driven and protocol-driven labs of 2030?

In this industry, the phrase "Big Data" is more than just a buzzword.

In the future, we will have to deal with new synonyms such as AI (Artificial Intelligence) and IoT (Internet of Things). In the hypothesis-driven lab with the strong driver of sustainability combined with the growth of ever higher quality artificial intelligence and algorithms, there will be more virtual "DMTA" (Design-Make-Test-Analyze) and less tangible ‘make’ and ‘test’.

So what new developments in data management will occur in the hypothesis-driven and protocol-driven labs of 2030?

- The ubiquity of IoT and 5G communication capabilities will lead to growth within the lab

- Widespread adoption and acceptance of accessible, interoperable, and reusable data

- Standards for presentation and system automation

- Data security and data protection

- The ubiquity of the “cloud”

- Digital twin approaches improve the representation of processes from a distance

- Quantum computers evaluate the flood of data and provide new information