In principle, the Y-FLEX mating face can be adapted to any standard ZIF, non-ZIF or LIF connector. However,

specially developed high-speed ZIF or non-ZIF connectors such as the HF507 series from Yamaichi are the most

suitable for achieving optimal performance.

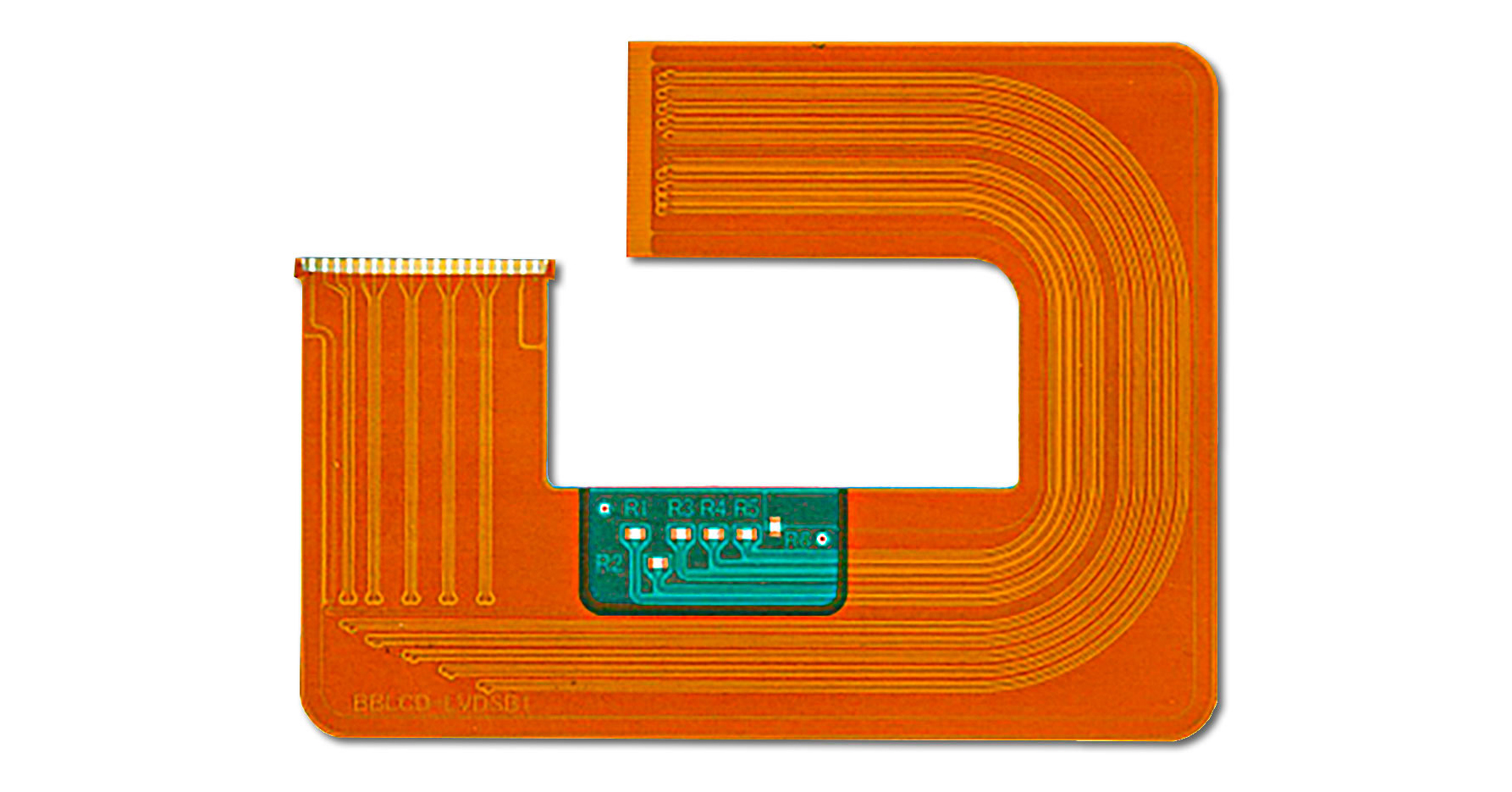

Y-FLEX compared with FFC and standard FPC

The biggest difference between Y-FLEX and standard FPCs lies in the insulation material. Compared with the

standard polyimides used in conventional FPCs, the LCP insulation material in the Y-FLEX exhibits a much

lower dielectric constant εr and a much lower dissipation factor tan δ at high frequencies. As a result,

attenuation is much lower, and the data transmission rates are much higher than in standard FPCs.

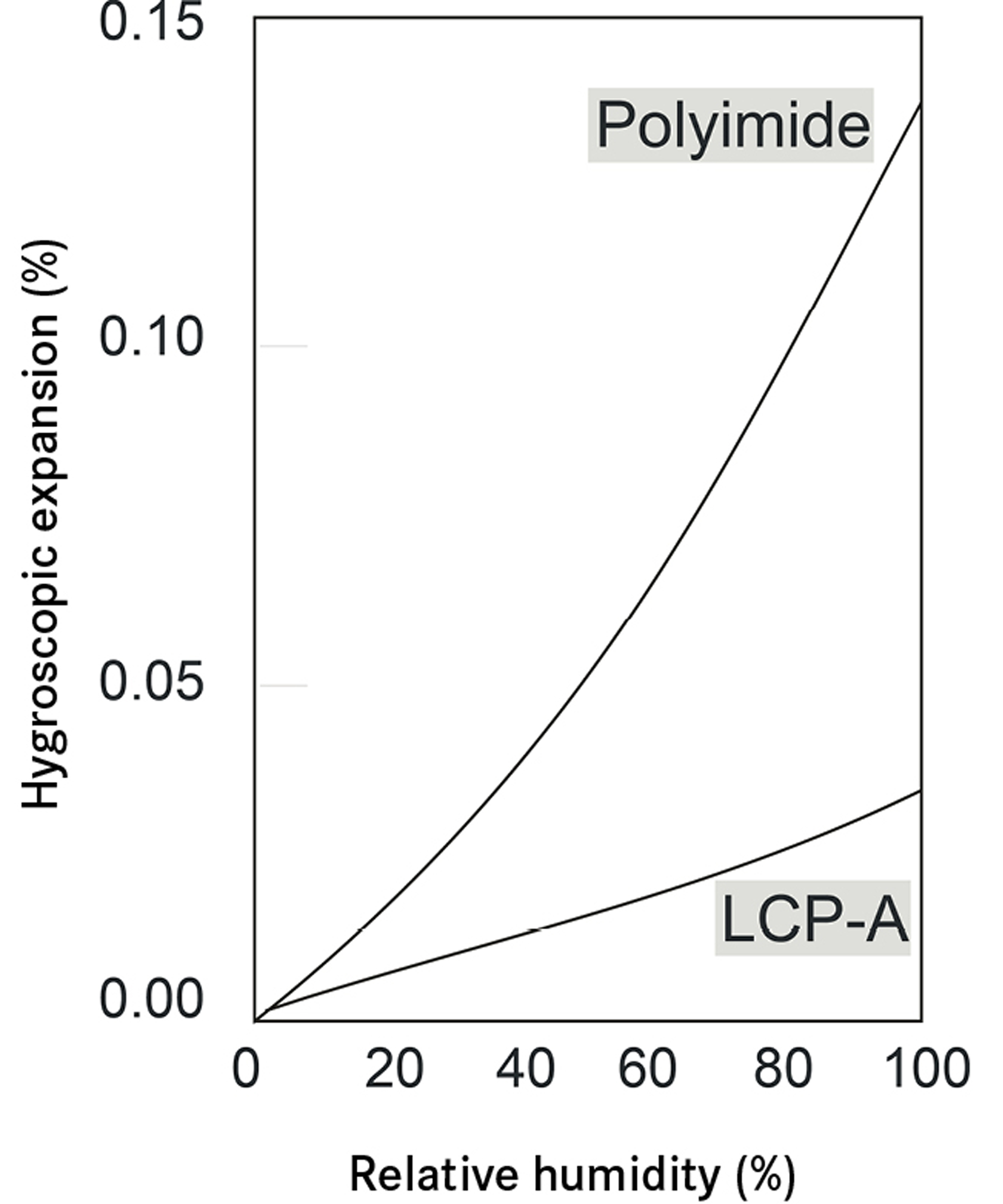

Moreover, LCP has superior hygroscopic properties compared with those of standard polyimide.

This makes

processing easier and allows trace spaces and widths of less than 30 µm to be realised with exceptionally

high accuracy. Use in high relative humidity conditions is also much more stable.

Y-FLEX compared with

micro‑coaxial cables

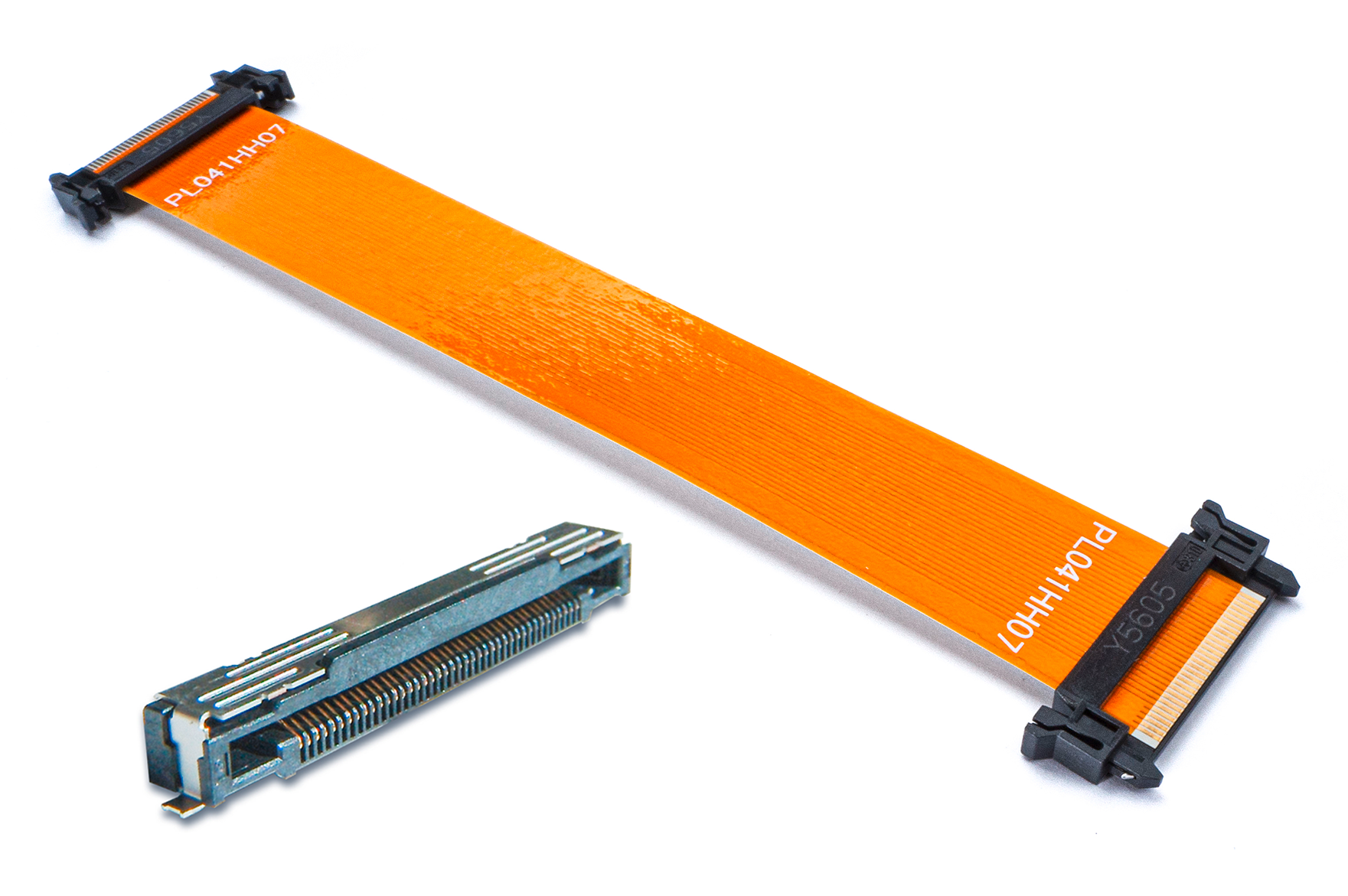

Transfer standards such as PCIe Gen 4 (16 GT/s), USB 3.2 Gen 2 (10 Gbps) or eDP HBR 3 (8.1 Gbps) can be

reached without any problems with Y-FLEX. In the latest measurements performed on the current Y-FLEX

generation, data rates of 56 Gbps (PAM4) were even realised over a cable length of 100 mm. Owing to the

described manufacturing process (above all the precision etching and use of the LCP material as an

insulator), the Y-FLEX has one very decisive advantage: it is 100 percent reproducible.

This means that all conductive traces are completely identical and thus achieve unprecedented constant

transmission characteristics over their entire lengths. In contrast, in a coaxial cable, the relationship

between inner and outer conductors differs along the cable due to the braid structure. An even more decisive

influencing factor is the assembly of the individual coaxial conductors on the

connector at the end of the line. There may be length and thus signal runtime differences in individual

lines here.

Hygroscopic properties of LCP and standard‑polyimide

Fit for future markets

A leading manufacturer of mobile communications and high-frequency measurement technology recognised the

outstanding technology of Y-FLEX several years ago and now uses it in a variety of projects, e. g. in 5G

testers and body scanners. In addition to measurement technology, Y-FLEX is used, for example, in autonomous

vehicles, data networking, image processing and medical technology.

▪ ds

Find out more now!

Find out more now!