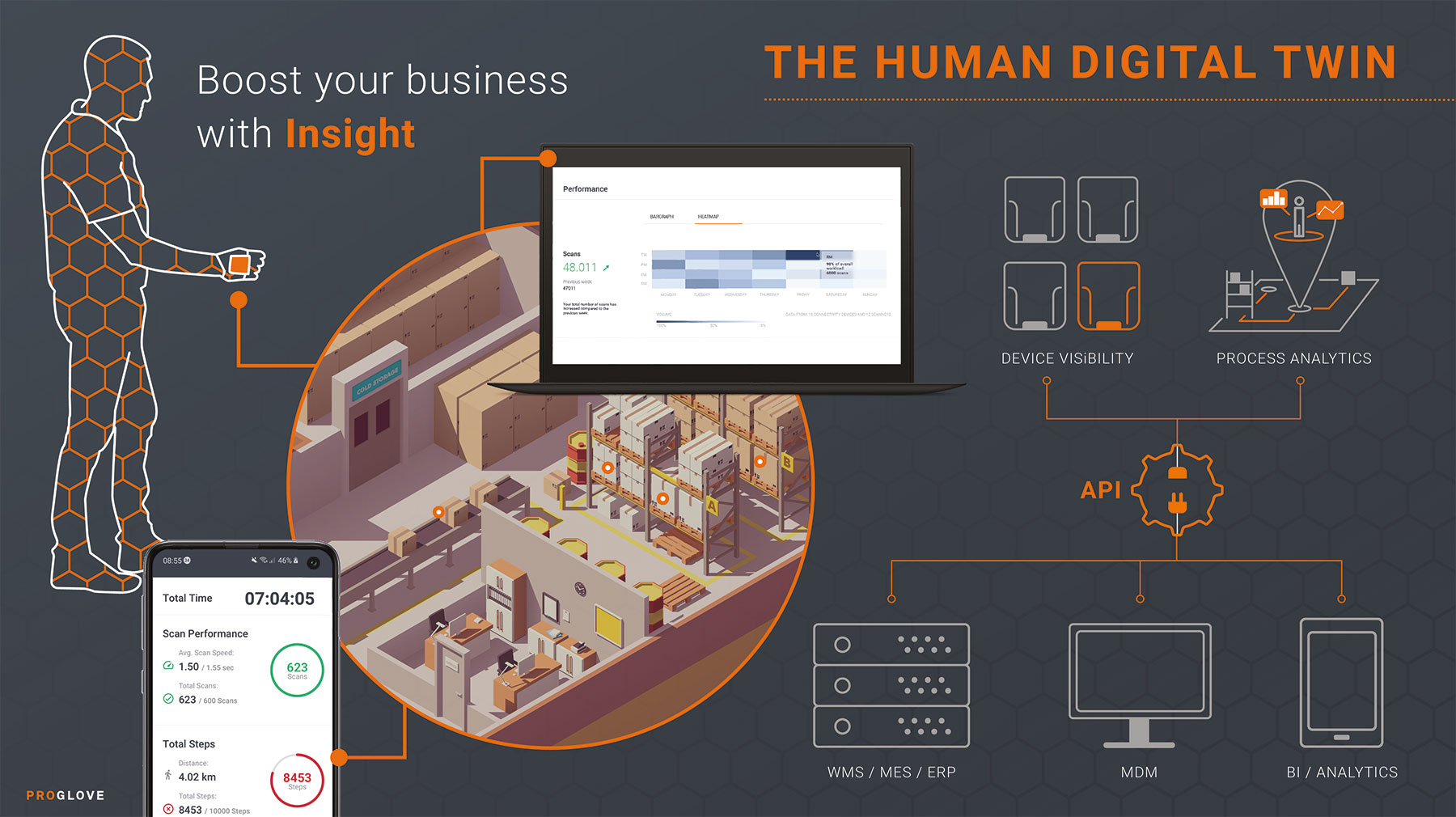

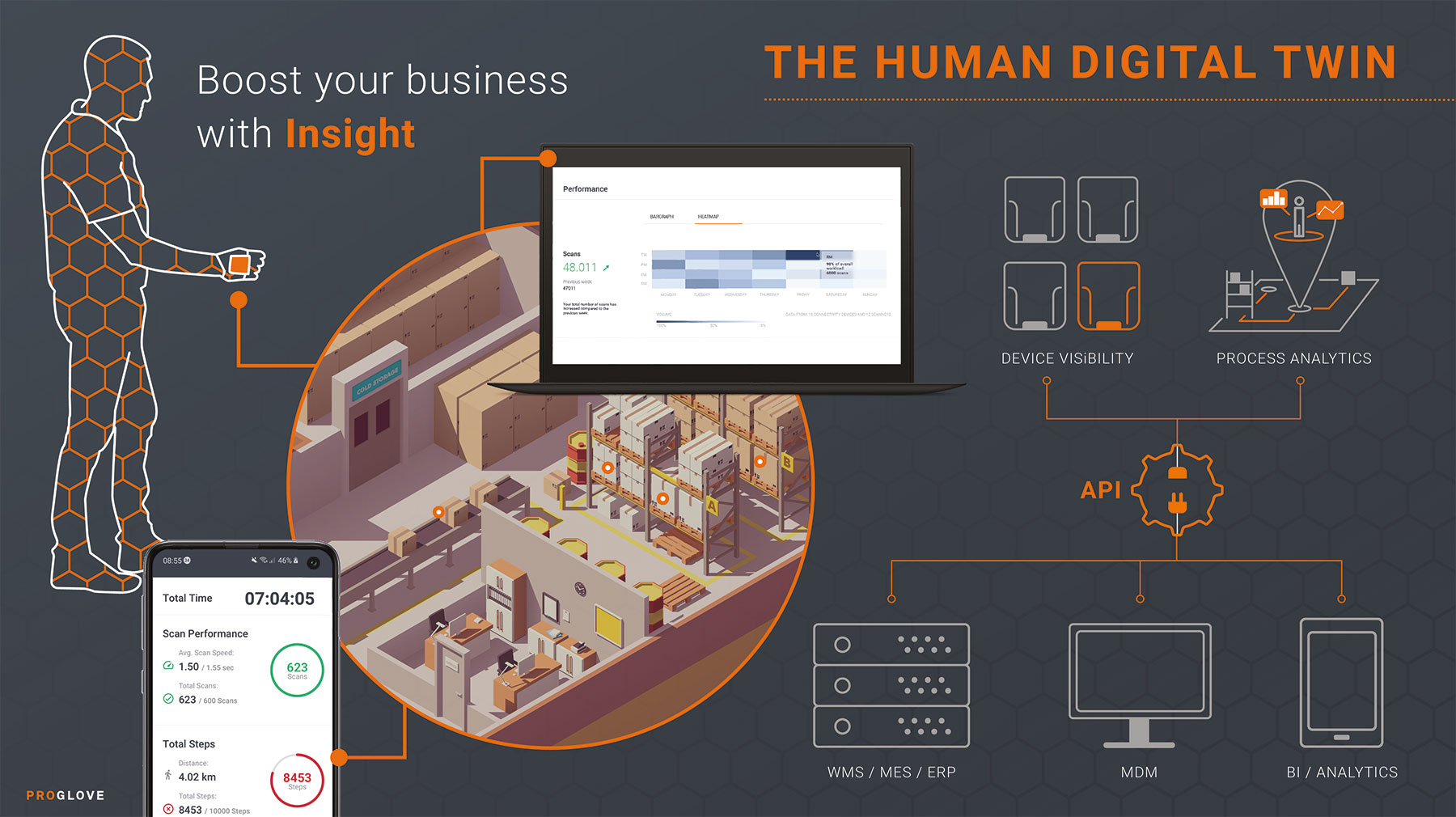

Human Digital Twin: The digital

counterpart to the human worker

Wearables from ProGlove make

humans a driving force of Industry 4.0 and digital transformation

The Digital Twin is a digitized model that maps the physical characteristics of a production environment as well

as the processes. But this mapping has its limitations, as it only includes data from machines and not from

humans. At the same time, human employees will continue to play an important role in the Fourth Industrial

Revolution, also known as Industry 4.0. The challenge lies in combining the data from machines with that of the

people working in the factory and evaluating it in real time. This is precisely where the concept of the Human

Digital Twin comes in.

In the context of Industry 4.0, the buzzwords Artificial Intelligence (AI) and Digital Twin often come up. In

the smart factory model, robots are supposed to take over the role of humans in order to be able to plan

resources precisely and reduce failures and errors. This full automation is neither possible today nor in the

near future—because it won't work without humans. Even technology pioneers like Amazon's Scott Anderson see it

that way. In his view, technology is still at least 10 years away from being able to fully automate a single

order picked by a worker in the warehouse [1].

Humans will remain crucial in Industry 4.0

The effects of the COVID-19 crisis in particular show that humans are indispensable. Logistics and supply chains

need a person’s dexterity, spontaneity and ability to work directly with others. These are the skills that

distinguish humans from robots. Evidence of this is provided, for example, by U.S. retail giant Walmart, which

ended its collaboration with a robotics company during the crisis after it became apparent that Walmart

employees could come up with similar results [2].

Technologies like AI, however, can create freedoms that promise a critical advantage for the role of humans. By

taking the pressure off, a person has the opportunity to evolve. For humans and machines to work together

without complications, preconditions must be put in place to communicate with each other and protect the worker.

Wearables create the basis for the Human Digital Twin

The goal is to support people with technology and enable them to concentrate on core tasks. In order for this to

succeed and for humans to be integrated into Industry 4.0, they need the appropriate equipment.

Human Digital Twin in the context of Industry 4.0

Wearables such as the smart glove scanners from ProGlove connect humans with the Internet of Things

(IoT) and thus represent the interface for human-machine collaboration