Electrified mobility:

Automation solutions from KUKA

The transformation of the automotive industry is in full swing worldwide, and concepts for electrified and

sustainable mobility are in demand. KUKA has also risen to the challenges in the production of electric

vehicles and is perfectly positioned in the field of intelligent automation for electromobility.

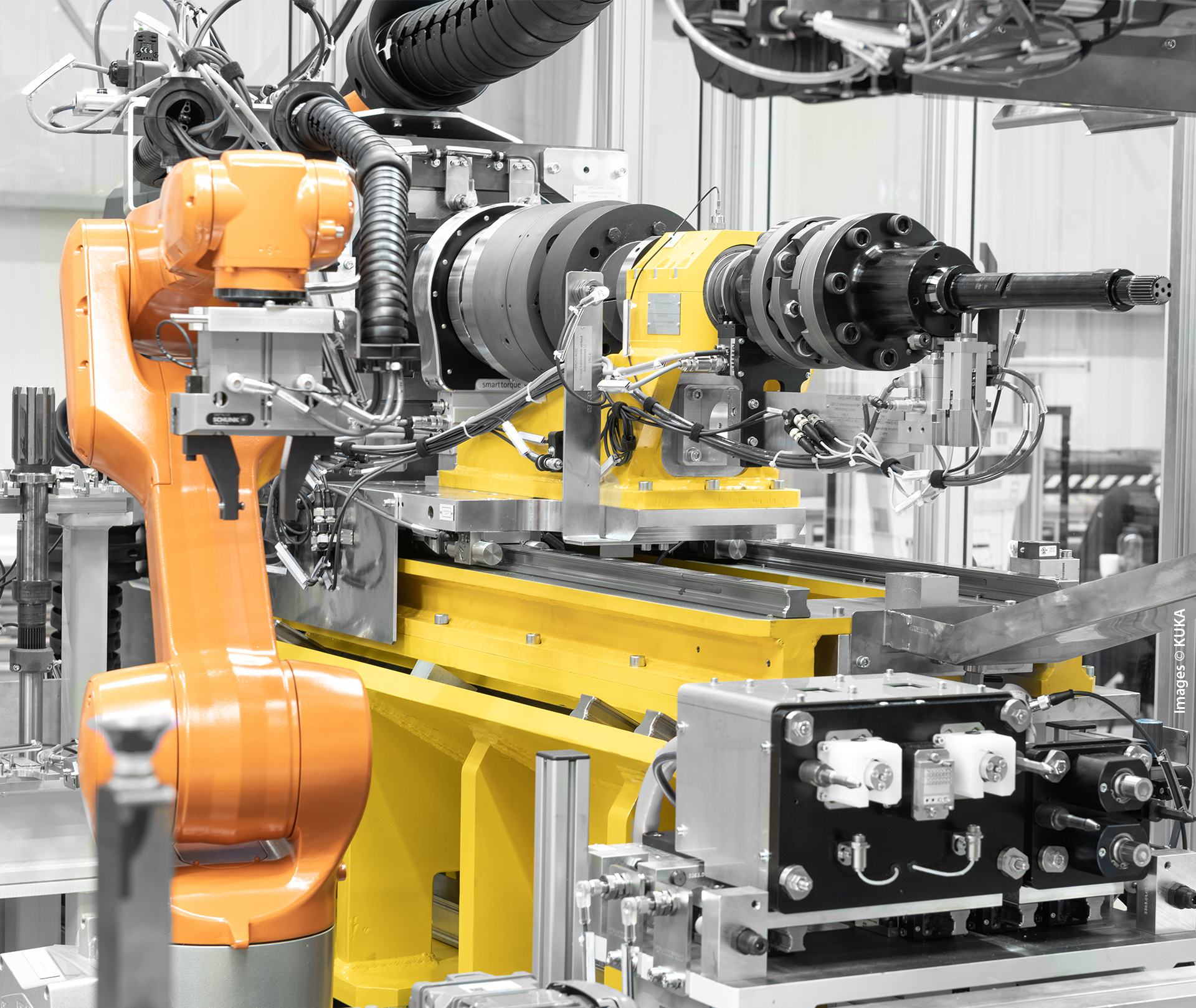

The KUKA team of experts, based at the Bremen site, invested around two years in the design, construction

and ultimately the successful commissioning of the eDrive test system. "With KUKA's automation know-how, we

help our customers achieve very high volume and variant flexibility," says Stefan Horner, Project Manager at

KUKA Assembly & Test in Bremen. "The special feature of this station: the ability to test a very high number

of variants with an automation level of 100 percent."

Highest precision

with maximum flexibility

The system is divided into two independent test areas. In the first area, the test object is checked for its

basic function, without adapted output shafts, and for its electrical safety. The second test area consists

of performance tests, which are all carried out with adapted load machines. Here, the use of a swivel unit

and the very rigid, adjustable traversing units for adapting the test objects with the load machines ensures

maximum variant diversity.

The swivel unit is used to pick up and position the test objects in the

prescribed test position. There, high torques can be taken off via driveline. This highly flexible test

system enables to test a wide variety of types on a single system.