Embedded Systems

From the PLC

to the IoT controller

When automating production lines according to IoT, the controls of all individual machines are networked

with one to another and integrated into the Internet. This requires IPC and communication functions, so

new hardware and software are necessary. MASS has developed a solution for this environment based on the

Raspberry Pi.

The solution is implemented with an IPC that also serves other requirements: for example, the HMI or B&B,

the external remote display of measurement results and machine states as well as intervals of maintenance.

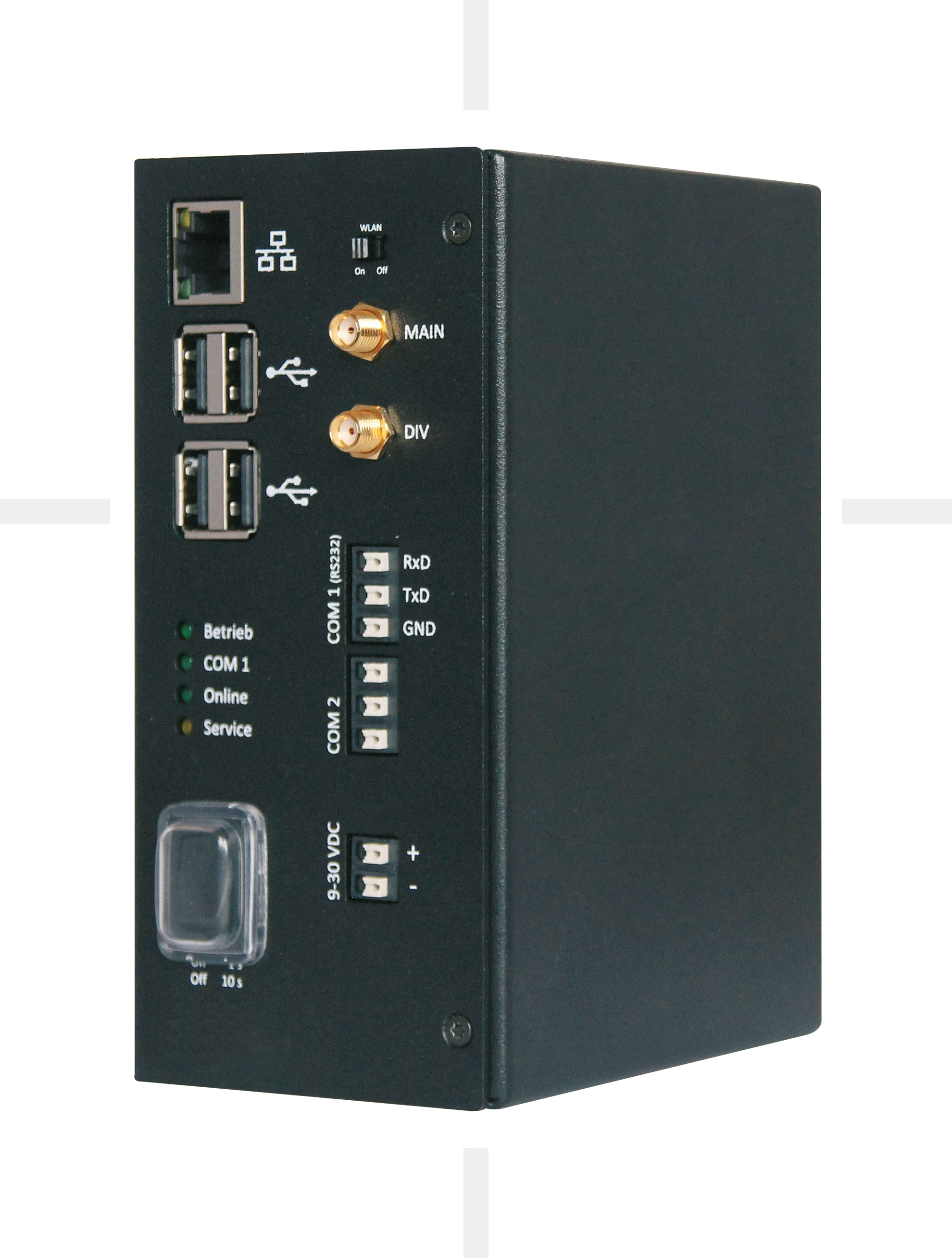

Such an IPC is not expensive if, for example, the Raspberry Pi processor is used. With over 32 million copies sold, it has become the market leader in the IPC processor family because it works with the widely spreaded programming languages CODESYS®, logi.CAD®, Python or many others. It also got internal connections for CSI camera, video/audio, I/O extension and interfaces USB 3.0, real-time clock with battery, RFID module and RS232/485.

Such an IPC is not expensive if, for example, the Raspberry Pi processor is used. With over 32 million copies sold, it has become the market leader in the IPC processor family because it works with the widely spreaded programming languages CODESYS®, logi.CAD®, Python or many others. It also got internal connections for CSI camera, video/audio, I/O extension and interfaces USB 3.0, real-time clock with battery, RFID module and RS232/485.