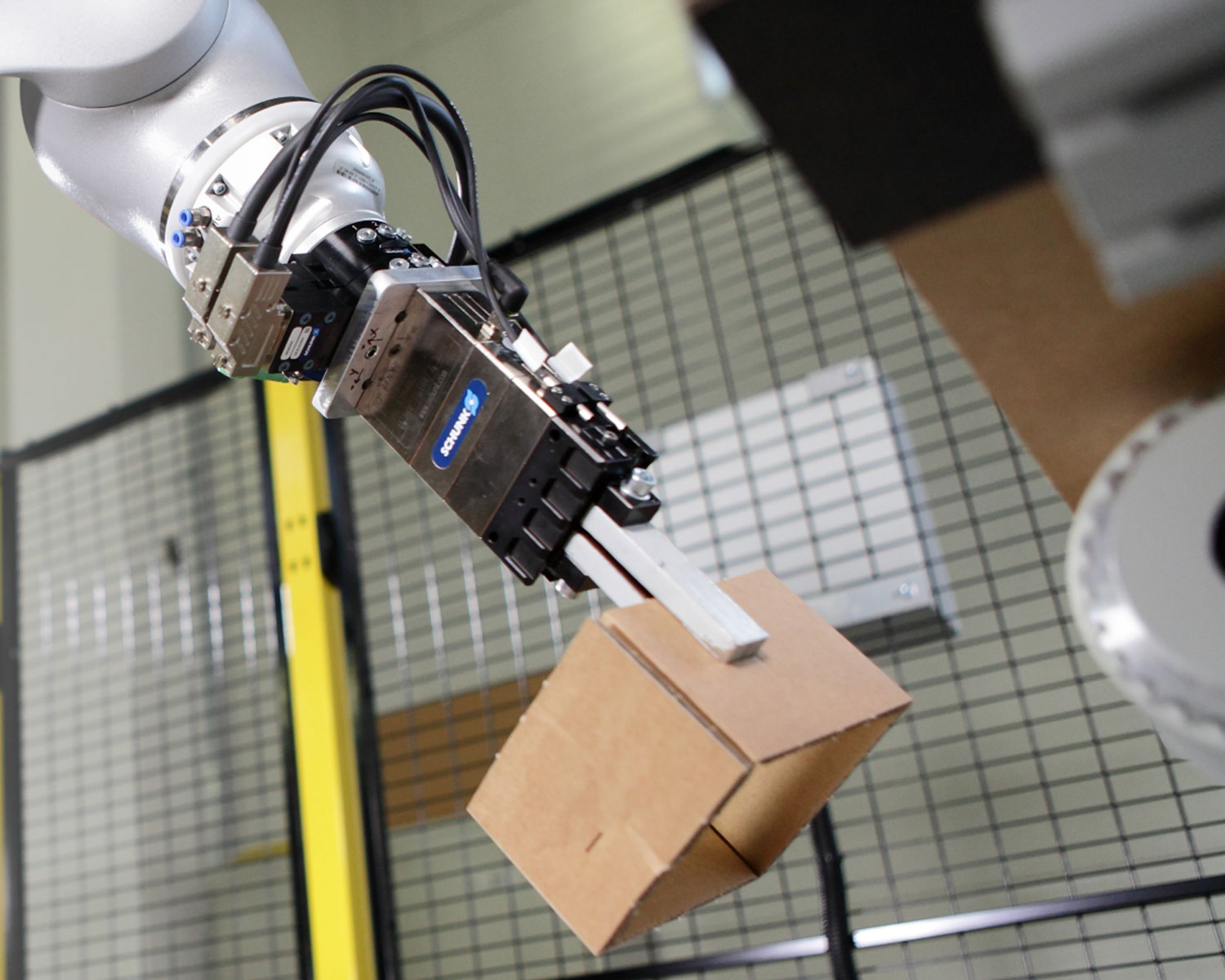

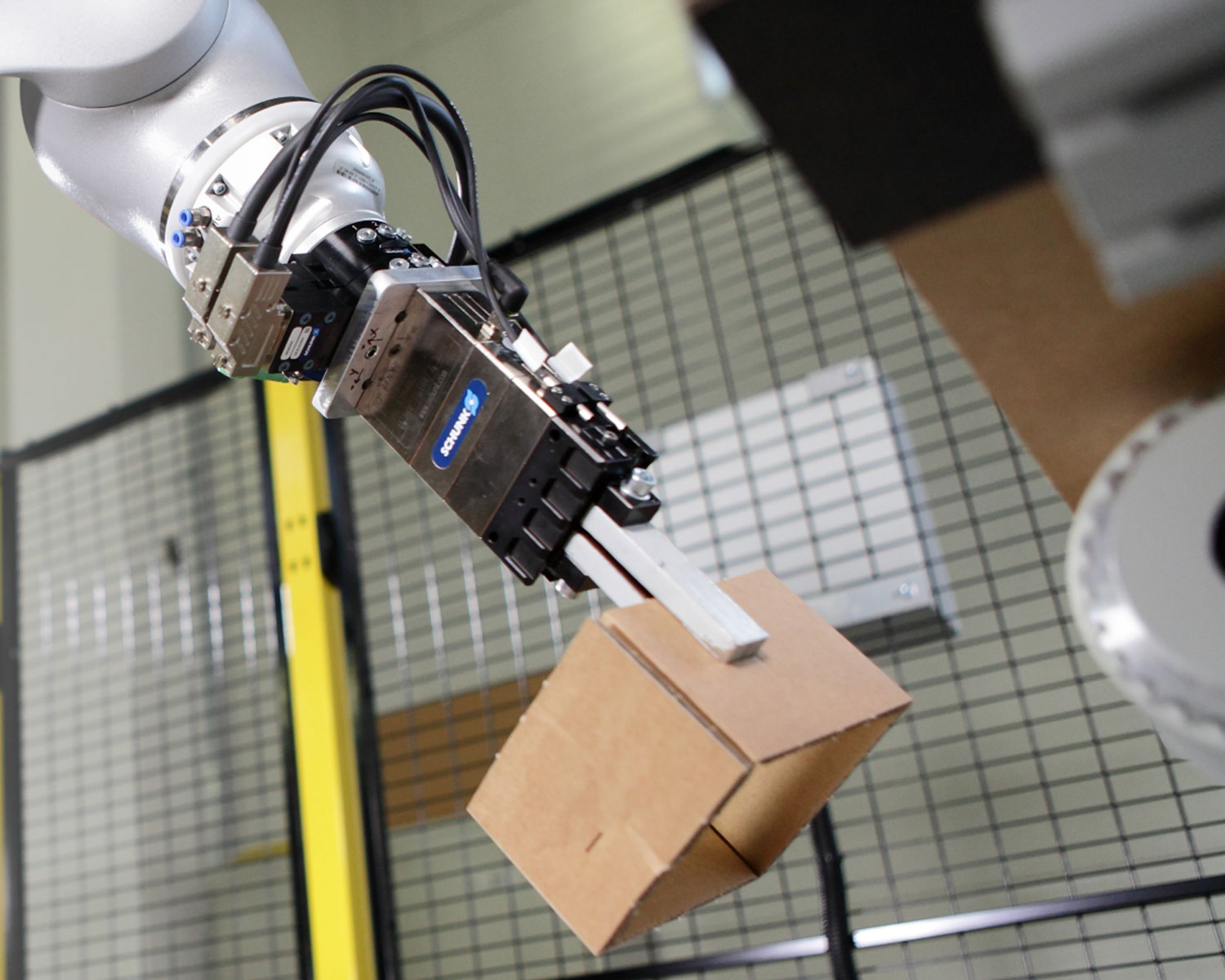

Sensitive and precise: the KUKA LBR iiwa folds corrugated sheets.

The lightweight LBR iiwa with its high‑performance servo control is able to detect contours quickly under force control

The scent of cardboard is in the air. It is a never-ending process of printing, stamping, folding and

stapling. The production of corrugated board at Tricor Packaging & Logistics AG runs as precisely as Swiss

clockwork.

Heavy-duty corrugated boxes for the automotive, chemical and capital goods industries roll off

the production line every second – and right in the middle of it all are lots of KUKA robots. “In 2004, we

commissioned a machine builder to develop a special system. However, during the start-up phase, the

integrator was unexpectedly no longer available and we desperately needed the support of specialists,”

remembers Lothar Heinzelmann, Engineering Projects manager at Tricor. The clock was ticking and production

had to start on a scheduled date.

KUKA Customer Service proved to be the competent partner for the job. “We

responded immediately after receiving a call from Tricor,” says Wolfgang Wanka, Head of Application

Programming at KUKA, describing the first contact. KUKA Customer Service offers immediate support in the

event of a crisis. This ‘first-aid response’ was the start of a long-standing partnership between both

companies.